Toolbox for Opto-Mechanical Components

From OHO - search engine for sustainable open hardware projects

|

Toolbox for Opto-Mechanical Components Basic Data Category: Business, industry URL (first publication): https://journals.plos.org/plosone/article?id=10.1371/journal.pone.0169832 Keywords: Construction elevator License: CC BY 4.0 Project status: Active

Technical documentation Maturity of the project: prototype

Assembly instructions are published: No Bill of materials is published: Yes

no no

Project management

Open-o-meter: 2 Product category: Business & Industrial

|

|

Description

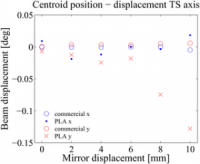

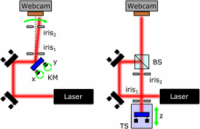

In this article we present the development of a set of opto-mechanical components (a kinematic mount, a translation stage and an integrating sphere) that can be easily built using a 3D printer based on Fused Filament Fabrication (FFF) and parts that can be found in any hardware store. Here we provide a brief description of the 3D models used and some details on the fabrication process. Moreover, with the help of three simple experimental setups, we evaluate the performance of the opto-mechanical components developed by doing a quantitative comparison with its commercial counterparts. Our results indicate that the components fabricated are highly customizable, low-cost, require a short time to be fabricated and surprisingly, offer a performance that compares favorably with respect to low-end commercial alternatives.

+ General Reviews