Technical drawings

The process of drawing up the plans is preferably carried out in the same program in which the CAD models were created (Inventor, SolidWorks, AutoCAD...). In this program, a drawing file [.idw or similar] must be created, from which the following pdf files must be generated:

General Pages

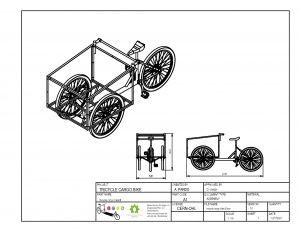

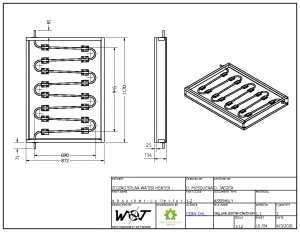

General Assembly Views

Here the project is represented in its entirety, using the appropriate scale, it includes orthogonal views, isometries, section views, detail views, general dimensions, weld details, among others, that show aspects of the assembly of the equipment in general. These views can span multiple pages, depending on the degree of complexity of the project.This section is identified with the code A1.

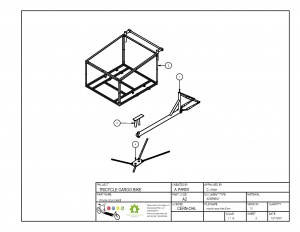

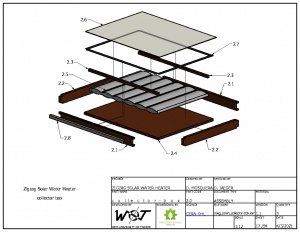

Single view of general explosion

On one page, the project's main assemblies should be displayed, separated and aligned according to their assembly logic, in an isometric view.Certain common components, such as screws, pipes, connecting elements, among others, may remain in the first level of the assembly or belong to the most important set with which they are related.This section is identified with the code A2.

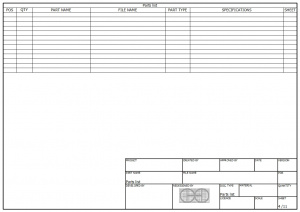

Complete part list.

In the same format as the Technical Drawings, a table must be added with the information of all the parts and assemblies, according to their hierarchical order.all fields must be filled according to the instructions explained below.It can span as many pages as necessary.This section is identified with the code B1, B2 ..., for each page.

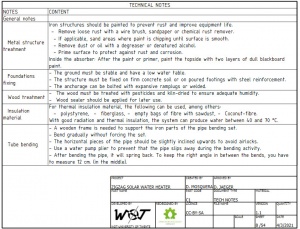

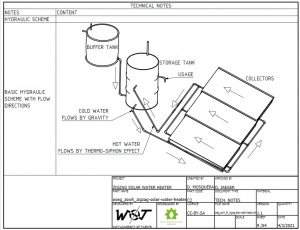

Technical Notes

Pages should be included for the aspects explained in Technical notes, confirming:

- General notes are in table format.

- Charts and diagrams are on later pages.

- Apply indents according to levels on the topics exposed.

- Use readable text.

- Use as many pages as necessary.

- This section is identified with the code C1, C2 ..., for each page.

Parts and Assemblies

Views of main assemblies or sub-assemblies

For each main assembly, general views of the assembly must be included, using the appropriate scale, including orthogonal views, isometries, section views, detail views, general dimensions, weld details, among others, that show aspects of the assembly's manufacture. These views can span multiple pages, depending on how complex the set is.This section is identified with the code corresponding to the set: 1, 2, 3 ...or 1.x, 2.x, 3.x for projects with more degrees of hierarchy.

Single explode view for main assemblies or sub-assemblies (if applicable)

For each set that requires more details, in addition to those indicated its views or that has some degree of complexity, a page must be included with its parts separated and aligned according to its assembly logic, in an isometric view.This section is identified with the code corresponding to the set: 1, 2, 3 ...or 1.x, 2.x, 3.x for projects with more degrees of hierarchy.

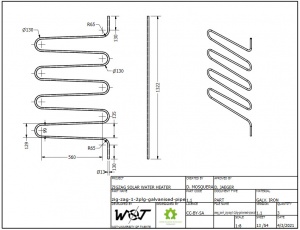

Views of parts or pieces

For the most basic levels of hierarchy, part drawings should be included with all the dimensions required for their manufacture, including orthogonal views, isometries, section views, detail views, dimensional tolerances (if applicable), surface quality symbols (if applicable).

Additional Notes

The developer must deliver:

- A single drawing file [.idw or similar] with all the above pages. Example: oseg_sp_screw-press.idw.

- A single .pdf file, generated from the drawing file. Example: oseg_sp_screw-press.pdf.

- A zipped folder with the separated pages in .dwg format. Example: oseg_sp_screw-press_DWG-files.zip.

In the Technical Drawings, standard parts are not included. View sheets may include orthogonal views, isometric views, cuts, details, annotations, etc. The established formats must be used.

The content of the application form must be written in English and must contain the following fields:

- PROJECT -> Name of the Project established or approved by OHO.

- CREATED BY -> abbreviation of the full name and surname of the developer (e.g. M. Serrantes).

- APPROVED BY -> abbreviation of the full name and surname of the director, e.g. D. Jaeger.

- PART NAME -> Name of the previously defined part or assembly, in case of the sheet for Parts list, enter Part List.

- PART CODE -> Part Code, already defined in the Parts list.

- DOCUMENT TYPE -> Depending on the content of the sheet, it can be: "PART" "ASSEMBLY" or "PARTS LIST".

- MATERIAL -> Indicate the material of the part, usually Steel C45, Steel A36.

- LICENCE -> Specify the license of the project, established or approved by OHO, e.g. "CERN-OHL".

- FILE NAME -> Filename of the part or assembly present in the sheet.

- VERSION -> Version number of the project, the first version is 1.0.

- QUANTITY -> Total quantity of the part or assembly in the sheet, within the complete assembly.

- SCALE -> Scale used by default in the sheet, specify in views if there are enlargements.

- SHEET -> Number of the sheet in the complete pdf in sheet/sheet format.

- DATE -> Date of last edition.

- DEVELOPED BY -> Organisation that developed the project, may include logo.

- REDESIGNED BY -> In case there are modifications in the design, place OSEG and your logo.

The sheet corresponding to the 'Part List' contains the same fields already defined in the Parts list of the Project, with the following exceptions:

- The 'PART CODE' field is replaced by 'FILE NAME'.

- The 'SHEET' column is included.

- The lines corresponding to each page of the Technical Notes section are included.

As an aid, you can use this template, which contains some defined styles, pages arranged to add views, macros to facilitate the correspondence between the pages of the plans and the Part list, among others.

For welded parts, it is preferred to use a simplified symbology, by means of weld beads seen in cut, or oriented arcs (caterpillar) for front views, as shown here. Arrows and annotations should be used only when it is very necessary to highlight some detail such as: coverage, shape and dimensions of the seam, type of weld, alloys, among others.