Logresse 2

From OHO - search engine for sustainable open hardware projects

|

Logresse 2 Basic Data Category: 3D printer URL (first publication): https://www.logre.eu/wiki/Logresse Keywords: 3D printer License: CC BY-SA 3.0 Project status: Active

Technical documentation Maturity of the project: production / DIY

CAD files are editable: Yes Assembly instructions are published: Yes Bill of materials is published: Yes

no no

Project management

Open-o-meter: 6 Product category: Business & Industrial

|

|

Description

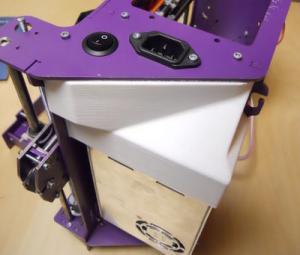

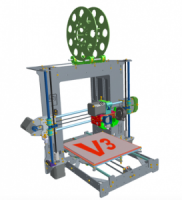

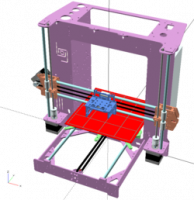

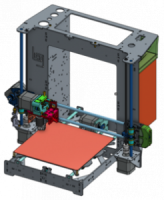

La Logresse is a 3D printer from Irobri's(http://www.reprap.org/wiki/P3Steel P3-Steel), a redesign of the(http://www.twelvepro.com/ Twelve Pro), itself based on Josef Prusa's(http://reprap.org/wiki/Prusa_i3 Prusa I3). Leonardo, the first version of the P3-Steel was built in April 2013, after Irobri attended a Maker Show in Zaragoza (Spain). Its frame, made of 3mm thick laser-cut steel sheet, ensures excellent rigidity and limits the use of printed plastic parts. The assembly of the chassis and adjustments are made easier by the interlocking of the plates fixed by means of captive nuts, and La Logresse takes all these advantages into account, with even greater rigidity. And by designing additional metal parts, especially those on the X axis and the slide, it further reduces plastic parts. It also provides additional space for power supply, various electronics, etc...

+ General Reviews