Difference between revisions of "Talk:Vice for drill press"

From OHO - search engine for sustainable open hardware projects

| Line 4: | Line 4: | ||

[[File:Rr-c3.jpg|thumb]] | [[File:Rr-c3.jpg|thumb]] | ||

--[[User:Dev2023|Dev2023]] ([[User talk:Dev2023|talk]]) 21: | : --[[User:Dev2023|Dev2023]] ([[User talk:Dev2023|talk]]) 21:58, 3 November 2023 (CET) | ||

The vise will be used to hold flat pieces such as bars and plates so it would not be misaligned, however, some wedges between the rails can be considered to improve alignment in the case mentioned. | : The vise will be used to hold flat pieces such as bars and plates so it would not be misaligned, however, some wedges between the rails can be considered to improve alignment in the case mentioned. | ||

== Part number 7 -- [[User:Aquilesmorillo|Aquilesmorillo]] ([[User talk:Aquilesmorillo|talk]]) 20:41, 3 November 2023 (CET) == | == Part number 7 -- [[User:Aquilesmorillo|Aquilesmorillo]] ([[User talk:Aquilesmorillo|talk]]) 20:41, 3 November 2023 (CET) == | ||

For this type of manufacturing, I think that a double nut on both sides is unnecessary, with one welding point and two nuts it is enough | For this type of manufacturing, I think that a double nut on both sides is unnecessary, with one welding point and two nuts it is enough | ||

Revision as of 22:58, 3 November 2023

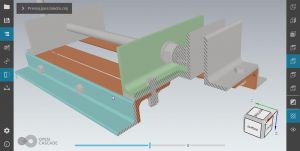

Part number 1 -- Xtech2020 review (talk) 20:13, 3 November 2023 (CET)

How do you ensure that the jaw moves aligned? An irregular piece can cause it to tilt and get stuck.

- The vise will be used to hold flat pieces such as bars and plates so it would not be misaligned, however, some wedges between the rails can be considered to improve alignment in the case mentioned.

Part number 7 -- Aquilesmorillo (talk) 20:41, 3 November 2023 (CET)

For this type of manufacturing, I think that a double nut on both sides is unnecessary, with one welding point and two nuts it is enough