Difference between revisions of "Talk:Vice for drill press"

From OHO - search engine for sustainable open hardware projects

| Line 4: | Line 4: | ||

[[File:Rr-c3.jpg|thumb]] | [[File:Rr-c3.jpg|thumb]] | ||

: The normal thing will be to use this vise for flat pieces such as bars, plates, etc., however I will take note of your observation, a small wedge inside the rail could help guarantee alignment | :The normal thing will be to use this vise for flat pieces such as bars, plates, etc., however I will take note of your observation, a small wedge inside the rail could help guarantee alignment | ||

== Part number 7 -- [[User:Aquilesmorillo|Aquilesmorillo]] ([[User talk:Aquilesmorillo|talk]]) 20:41, 3 November 2023 (CET) == | == Part number 7 -- [[User:Aquilesmorillo|Aquilesmorillo]] ([[User talk:Aquilesmorillo|talk]]) 20:41, 3 November 2023 (CET) == | ||

For this type of manufacturing, I think that a double nut on both sides is unnecessary, with one welding point and two nuts it is enough | For this type of manufacturing, I think that a double nut on both sides is unnecessary, with one welding point and two nuts it is enough | ||

Revision as of 22:19, 3 November 2023

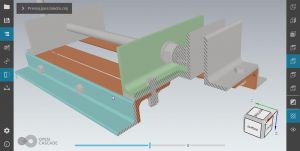

Part number 1 -- Xtech2020 review (talk) 20:13, 3 November 2023 (CET)

How do you ensure that the jaw moves aligned? An irregular piece can cause it to tilt and get stuck.

- The normal thing will be to use this vise for flat pieces such as bars, plates, etc., however I will take note of your observation, a small wedge inside the rail could help guarantee alignment

Part number 7 -- Aquilesmorillo (talk) 20:41, 3 November 2023 (CET)

For this type of manufacturing, I think that a double nut on both sides is unnecessary, with one welding point and two nuts it is enough