Difference between revisions of "Open Hardware Loom, Open Source Ecology Germany"

From OHO - search engine for sustainable open hardware projects

(Created page with "{{Projekt |subcat=Looms |projectname=Open Hardware Loom, Open Source Ecology Germany |projectnameES=Open Hardware Telar, Open Source Ecology Germany |projectnameDE=Open Hardwa...") |

|||

| (10 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

{{Projekt | {{Projekt | ||

|Images={{ProjektImages | |||

|projectimage=OHLOOM complete.png | |||

}}{{ProjektImages | |||

|projectimage=WindUp 40.jpg | |||

}}{{ProjektImages | |||

|projectimage=WindUp 37.jpg | |||

}}{{ProjektImages | |||

|projectimage=WindUp 39.jpg | |||

}}{{ProjektImages | |||

|projectimage=Assembly Guide-1.jpg | |||

}} | |||

|subcat=Looms | |subcat=Looms | ||

|projectname=Open Hardware Loom, Open Source Ecology Germany | |projectname=Open Hardware Loom OHLOOM, Open Source Ecology Germany | ||

|projectnameES=Open Hardware Telar, Open Source Ecology Germany | |projectnameES=Open Hardware Telar OHLOOM, Open Source Ecology Germany | ||

|projectnameDE=Open Hardware Webstuhl, Open Source Ecology Germany | |projectnameDE=Open Hardware Webstuhl OHLOOM, Open Source Ecology Germany | ||

|firstin=https://wiki.opensourceecology.de/Open_Hardware-Webstuhl_%E2%80%93_OHLOOM | |firstin=https://wiki.opensourceecology.de/Open_Hardware-Webstuhl_%E2%80%93_OHLOOM | ||

|trans_status=MT | |trans_status=MT | ||

| | |licence=CCBYSA40 | ||

|organization=Open Source Ecology Germany e.V. | |||

|project_status=active | |||

|design_files_pub=yes | |||

|cad_link=https://gitlab.com/OSEGermany/ohloom | |||

|cad_files_editable=yes | |||

|mechanical_licence=CCBYSA40 | |||

|electronic_files_pub=no | |||

|software_files_pub=no | |||

|assembly_inst_pub=yes | |||

|bill_materials_pub=no | |||

|contributing_guide_pub=no | |||

|issue_management_system=no | |||

|versioning_system=no | |||

|contains_pdf_drawings=yes | |||

|TechDoc={{ProjektComponent | |||

|cmptitle=PDF with all drawings | |||

|cmpfile1=TechDraw Catalog.pdf | |||

}}{{ProjektComponent | |||

|cmptitle=STL-files part 1 | |||

|cmpfile1=ClampRing.stl | |||

|cmpfile2=CombModul.stl | |||

|cmpfile3=PoleBase.stl | |||

|cmpfile4=RatchetPawl.stl | |||

|cmpfile5=RatchetWheel.stl | |||

}}{{ProjektComponent | |||

|cmptitle=STL-files part 2 | |||

|cmpfile1=ScrewSocket.stl | |||

|cmpfile2=ScrewSocket4ScrewHead.stl | |||

|cmpfile3=Warpclothbeam 1.stl | |||

|cmpfile4=Warpclothbeam 2.stl | |||

|cmpfile5=Warpclothbeam 3.stl | |||

}}{{ProjektComponent | |||

|cmptitle=STL-files part 3 | |||

|cmpfile1=Warpclothbeam 4.stl | |||

}} | |||

|Materials={{ProjektMaterials | |||

|matpartnumber=0 | |||

|matquantity=1 | |||

|matdesc=OHLOOM complete | |||

|matpdffile=Assembly.pdf | |||

}}{{ProjektMaterials | |||

|matpartnumber=1 | |||

|matdesc=Corpus Frame: | |||

}}{{ProjektMaterials | |||

|matpartnumber=2 | |||

|matquantity=2 | |||

|matdesc=Frameside | |||

|matspec=Sidepart, rawdim 580 x 140 x20 mm, UPK-No. 19040100 | |||

|matpdffile=Frameside.pdf | |||

}}{{ProjektMaterials | |||

|matpartnumber=3 | |||

|matquantity=2 | |||

|matdesc=Combholder | |||

|matspec=Combholder, rawdim 118 x 60 x 20 mm, UPK-No. 19040101 | |||

}}{{ProjektMaterials | |||

|matpartnumber=4 | |||

|matquantity=2 | |||

|matdesc=Crossbeam | |||

|matspec=Cross-link framepart, rawdim 572 x 100 x 20 mm, UPK-No. 19040102 | |||

|matpdffile=Crossbeam.pdf | |||

}}{{ProjektMaterials | |||

|matpartnumber=5 | |||

|matquantity=2 | |||

|matdesc=Warpclothbeam | |||

|matspec=Warpbeam and Clothbeam, rawdim 710 x 40 x 40 mm�; alternatetivly a cylindrical wooden shaft with 710 mm length and 35mm diameter will do as well, UPK-No. 19040103 | |||

|matpdffile=Warpclothbeam P1-P4.pdf | |||

}}{{ProjektMaterials | |||

|matpartnumber=6 | |||

|matquantity=2 | |||

|matdesc=Ratchetpawl | |||

|matspec=Ratchet break / stopper, rawdim 130 x 20 x 20 mm, UPK-No. 19040104 | |||

|matpdffile=RatchetPawl.pdf | |||

}}{{ProjektMaterials | |||

|matpartnumber=7 | |||

|matquantity=2 | |||

|matdesc=Ratchetwheel | |||

|matspec=Ratchet wheel, 3D-printed, UPK-No. 19040109 | |||

|matpdffile=RatchetWheel.pdf | |||

}}{{ProjektMaterials | |||

|matpartnumber=8 | |||

|matquantity=2 | |||

|matdesc=Clampring | |||

|matspec=Ratchet clampring, 3D-printed, UPK-No. 19040112 | |||

|matpdffile=ClampRing.pdf | |||

}}{{ProjektMaterials | |||

|matpartnumber=9 | |||

|matquantity=1 | |||

|matdesc=Stringstick | |||

|matspec=Stick for connecting the heddle strings, rawdim 560 x 22 x 6 mm, UPK-No. 19040113 | |||

|matpdffile=Stringstick.pdf | |||

}}{{ProjektMaterials | |||

|matpartnumber=10 | |||

|matdesc=Weaving Comb: | |||

}}{{ProjektMaterials | |||

|matpartnumber=11 | |||

|matquantity=2 | |||

|matdesc=Slotbeam | |||

|matspec=Upper and lower framepart, rawdim 566 x 24 x 22 mm, UPK-No. 19040107 | |||

|matpdffile=Slotbeam.pdf | |||

}}{{ProjektMaterials | |||

|matpartnumber=12 | |||

|matquantity=4 | |||

|matdesc=Combmodul | |||

|matspec=Modul for building the comb, 3D-printed, UPK-No. 19040110 | |||

|matpdffile=CombModul.pdf | |||

}}{{ProjektMaterials | |||

|matpartnumber=13 | |||

|matdesc=Hardware: | |||

}}{{ProjektMaterials | |||

|matpartnumber=14 | |||

|matquantity=4 | |||

|matdesc=W35x4 | |||

|matspec=Woodscrew f. Combholder, UPK-No. 19040105 | |||

|matpdffile=Combholder.pdf | |||

}}{{ProjektMaterials | |||

|matpartnumber=15 | |||

|matquantity=8 | |||

|matdesc=W60x5 | |||

|matspec=Woodscrew f. Crosslink, UPK-No. 19040106 | |||

}}{{ProjektMaterials | |||

|matpartnumber=16 | |||

|matquantity=2 | |||

|matdesc=M8x180thread | |||

|matspec=Threaded rod M8 x 180 mm, for weaving comb, UPK-No. 19040108 | |||

}}{{ProjektMaterials | |||

|matpartnumber=17 | |||

|matquantity=8 | |||

|matdesc=M8nut | |||

|matspec=M8 nut, for weaving comb, UPK-No. 19040109 | |||

}}{{ProjektMaterials | |||

|matpartnumber=18 | |||

|matquantity=8 | |||

|matdesc=M6x70cyl | |||

|matspec=M6 cylinder screw, for ratchetwheel and clampring, UPK-No. 19040111 | |||

}}{{ProjektMaterials | |||

|matpartnumber=19 | |||

|matquantity=8 | |||

|matdesc=M6nut | |||

|matspec=M6 nut, for ratchetwheel and clampring, UPK-No. 17092308 | |||

}}{{ProjektMaterials | |||

|matpartnumber=20 | |||

|matquantity=1 | |||

|matdesc=Shuttle | |||

|matspec=Shuttle, for weaving, rawdim 500 x 45 x 6 mm, UPK-No. 19040114 | |||

|matpdffile=Shuttle.pdf | |||

}}{{ProjektMaterials | |||

|matpartnumber=21 | |||

|matdesc=Warpclothbeam shaft | |||

|matparttype=standard | |||

|matpdffile=Warpclothbeam Shaft.pdf | |||

}}{{ProjektMaterials | |||

|matpartnumber=22 | |||

|matdesc=Pole base | |||

|matparttype=production | |||

|matpdffile=PoleBase.pdf | |||

}} | |||

|certificate_requested=No | |certificate_requested=No | ||

|certificate_status=in process | |||

}} | }} | ||

Latest revision as of 09:54, 19 July 2021

|

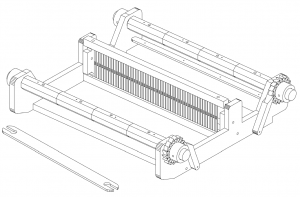

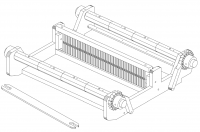

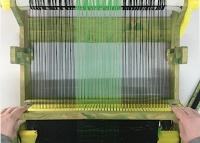

Open Hardware Loom OHLOOM, Open Source Ecology Germany Basic Data Category: Looms URL (first publication): https://wiki.opensourceecology.de/Open_Hardware-Webstuhl_%E2%80%93_OHLOOM License: CC BY-SA 4.0 Organization: Open Source Ecology Germany e.V. Project status: Active Certification status: In process Technical documentation

Contains PDF-drawings: Yes CAD files are editable: Yes Assembly instructions are published: Yes Bill of materials is published: No

no no

|

|

Technical documentation

PDF with all drawings | |

Files: | |

STL-files part 1 | |

Files: | |

STL-files part 2 | |

Files: | |

STL-files part 3 | |

Files: | |

+ General Reviews

Parts list

| Pos. | Qty. | Part Name | Part code | Part Type | Specifications | Review Status | Show All Comments | |

|---|---|---|---|---|---|---|---|---|

| 0 | 1 | OHLOOM complete | ||||||

| 1 | Corpus Frame: | |||||||

| 2 | 2 | Frameside | Sidepart, rawdim 580 x 140 x20 mm, UPK-No. 19040100 | |||||

| 3 | 2 | Combholder | Combholder, rawdim 118 x 60 x 20 mm, UPK-No. 19040101 | |||||

| 4 | 2 | Crossbeam | Cross-link framepart, rawdim 572 x 100 x 20 mm, UPK-No. 19040102 | |||||

| 5 | 2 | Warpclothbeam | Warpbeam and Clothbeam, rawdim 710 x 40 x 40 mm�; alternatetivly a cylindrical wooden shaft with 710 mm length and 35mm diameter will do as well, UPK-No. 19040103 | |||||

| 6 | 2 | Ratchetpawl | Ratchet break / stopper, rawdim 130 x 20 x 20 mm, UPK-No. 19040104 | |||||

| 7 | 2 | Ratchetwheel | Ratchet wheel, 3D-printed, UPK-No. 19040109 | |||||

| 8 | 2 | Clampring | Ratchet clampring, 3D-printed, UPK-No. 19040112 | |||||

| 9 | 1 | Stringstick | Stick for connecting the heddle strings, rawdim 560 x 22 x 6 mm, UPK-No. 19040113 | |||||

| 10 | Weaving Comb: | |||||||

| 11 | 2 | Slotbeam | Upper and lower framepart, rawdim 566 x 24 x 22 mm, UPK-No. 19040107 | |||||

| 12 | 4 | Combmodul | Modul for building the comb, 3D-printed, UPK-No. 19040110 | |||||

| 13 | Hardware: | |||||||

| 14 | 4 | W35x4 | Woodscrew f. Combholder, UPK-No. 19040105 | |||||

| 15 | 8 | W60x5 | Woodscrew f. Crosslink, UPK-No. 19040106 | |||||

| 16 | 2 | M8x180thread | Threaded rod M8 x 180 mm, for weaving comb, UPK-No. 19040108 | |||||

| 17 | 8 | M8nut | M8 nut, for weaving comb, UPK-No. 19040109 | |||||

| 18 | 8 | M6x70cyl | M6 cylinder screw, for ratchetwheel and clampring, UPK-No. 19040111 | |||||

| 19 | 8 | M6nut | M6 nut, for ratchetwheel and clampring, UPK-No. 17092308 | |||||

| 20 | 1 | Shuttle | Shuttle, for weaving, rawdim 500 x 45 x 6 mm, UPK-No. 19040114 | |||||

| 21 | Warpclothbeam shaft | Standard | ||||||

| 22 | Pole base | Production | ||||||