Based on the DIN 2221 standard, among others, OHO has established a series of stages in which the satisfactory completion of this project was carried out

1 Feasibility study

- Regarding the equipment for working with metals that may be needed in sustainable development initiatives, there are small and medium-scale lathes, for which OHO has proposed to evaluate the feasibility of designing and building equipment that serves to supply some cylindrical parts, where a certain level of quality is guaranteed in accordance with manufacturing processes that do not require very high precision.

- It was observed on the internet that there are already some DIY (homemade) devices, which, apparently, can fulfill this objective, however:

- The number of examples found is not very numerous, limiting the possibility of strengthening the idea of an open source lathe, made with totally accessible materials and processes, for practical applications, in low-income areas.

- Essential details about dimensions and assembly are not always well explained, plans are generally not available.

- The reviewed DIY cases are based on replicating commercial equipment or building a device with the necessary components, but without a technical analysis of the design and feasibility of the proposed solutions.

- Proposal (all aspects are subject to revision)

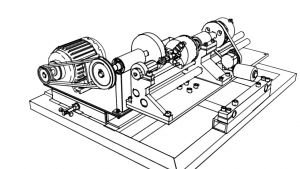

- The design and construction of a small-scale lathe is then proposed, which can be manufactured in a basic workshop, with the following characteristics:

- That can process non-hardened steel parts

- Maximum dimensions of the pieces to be processed: Diameter: 50mm, Length: 400mm

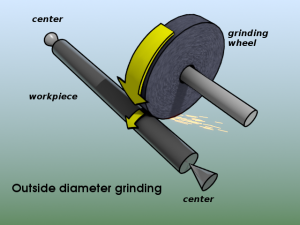

- That removes the material with abrasive wheels, this in order to reduce the forces transmitted to the structure and reduce costs for tool replacement

- The equipment must have a simplified design, for which some or all of these solutions can be applied:

- Main motor reused or purchased from other domestic components or adapt a high-performance manual drill (1/2”) In both cases, it must be possible to regulate the speed of rotation, which is facilitated in the case of the drill.

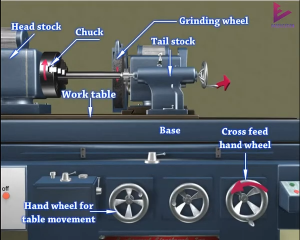

- Includes a clamp head and tailstock, which can be purchased.

- The grinding subsystem can consist of a bench grinder adapted to the equipment, with the capacity for axial and transversal movement and rotation in the vertical axis.

- See this link (adapted bench grinder)

The use of high precision linear bearings will make the project more expensive

- The equipment must have axial and transversal displacement guides, for which the use of tubes or calibrated bars is proposed, this to guarantee stability in movements and reduces costs and complexity compared to the use of bearings linear, dovetail, etc.

- Comparative analysis on the type of process to carry out

- A comparative test was carried out between the use of abrasive stones as a tool for a turning process, versus turning with usual cutting blades, for which an example was raised with the following premises:

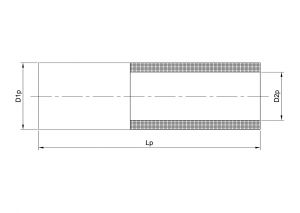

- D1p: Initial diameter of the part: 38mm

- D2p: Final diameter of the piece: 25mm

- Lp: Piece length: 100mm

- It was proposed to know in both cases (grinding or turning):

- Machining time for one part

- Weekly production

- The force generated in the lathe and

- The cost in tooling for a production of 1000 pieces

- The following results were obtained:

- Grinding process

- Characteristics of the tool used

- Cost of an abrasive wheel: 11USD

- Abrasive wheel thickness: 25mm

- Abrasive wheel outside diameter: 152.4mm

- Internal diameter of abrasive wheel (useful): 50mm

- Machining parameters

- Abrasive wheel speed: 30m/s

- Speed of the piece in grinding: 0.22m/s

- Feed in grinding: 17.5mm/rev

- Depth of pass in grinding: 0.01mm

- Rotational speed of abrasive wheel: 5662rpm

- Rotational speed of the piece in grinding: 133rpm

- Performance

- Time of one pass in grinding: 6.4s

- Number of passes in grinding: 650

- Time per piece in grinding: 69min

- Weekly production: 144 pieces/week

- Tooling cost

- Quantity of pieces per abrasive wheel: 632

- Cost of abrasive wheels to make 1000 pieces: 17USD

- Mechanical load

- Absorbed power in grinding: 1.22HP

- Grinding torque : 1.5N-m

- Force transmitted in grinding : 1174N

- Turning process

- Characteristics of the tool used

- Cost of a tool: 25USD

- Number of sharps per tool: 10

- Lifespan of a sharp tool: 50min

- Machining parameters

- Cutting speed in turning: 16m/min

- Feed in turning: 0.5mm/rev

- Depth of pass in turning: 1mm

- Rotational speed in turning: 134rpm

- Performance

- Time of one pass in turning: 89s

- Number of passes in turning: 7

- Time per part in turning: 10min

- Weekly production: 1039 pieces/week

- Tooling cost

- Number of pieces per blade: 51

- Cost of blades to make 1000 pieces: 485USD

- Mechanical load

- Absorbed power in turning : 2.5HP

- Turning torque : 129N-m

- Force transmitted in turning : 2384N

- Conclusions:

- Production performance drops significantly in the case of manufacturing the parts through the grinding process, achieving 15% of what can be produced by turning in the same period of time, this is due to the fact that the depth of past has a relationship of 3 to 100 with respect to both scenarios.

- When reviewing costs per tooling, the grinding process is far preferred over turning, grinding wheels were estimated for a wear ratio of 80 (volumetric ratio of wear to metal removed).

- Regarding the mechanical load resulting from machining, it could be determined that it increases in a proportion of 1:3 in the case of turning, so the respective forecasts must be taken when designing the bed, which It will support loads in the order of 300kgf, assuming a safety factor of 30%.

- Due to the above, this project will be oriented to the design and construction of a lathe that integrates the necessary components to carry out the cylindrical grinding process, mainly.

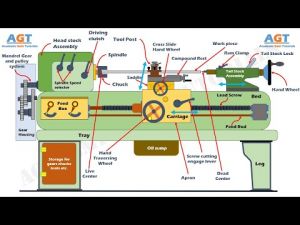

- Sub processes to be carried out in the machine

- The objective of this lathe to design is the production of parts that can usually be required in a non-industrialized workshop, with the capacity to manufacture machines and devices of medium complexity, through the use of Appropriate Technologies. In this sense, the operations that can normally be expected in a lathe to cover the aforementioned production and the fulfillment of such operations by the machine to be designed are indicated below:

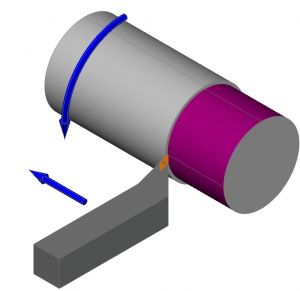

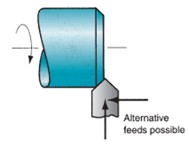

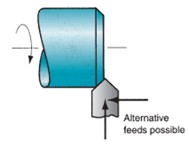

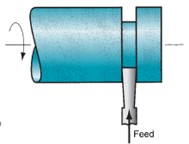

Turning

For parts that require the use of center point or steady rest, the non-interference of moving parts must be verified.

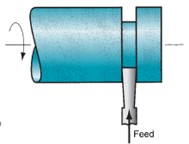

Facing

The radius of the part must be less than or equal to the useful width of the abrasive wheel.

Conical turning

The abrasive turning mechanism must be able to rotate and move obliquely on the cross slide (tool post grinder).

Chamfering

The abrasive turning mechanism must be able to rotate and move obliquely on the cross slide (tool post grinder).

Grooving, Cutoff

Requires the use of low thickness abrasive (cutting) wheels.

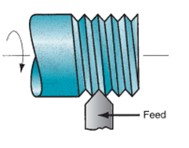

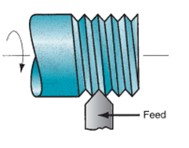

Threading

It only applies to finishing processes and requires mechanisms for automatic feed

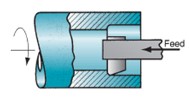

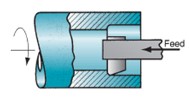

Internal turning

Requires the use of smaller diameter accessories, for example, diamond-tipped tools.

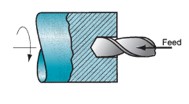

Drilling

It is an exclusive process for the use of drilling bits (metal in this case).

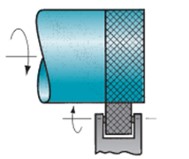

Knurling

It is an exclusive process for the use of knurling accessories.

Manufacturing as OSAT technology is possible?

- Required materials and components can be sourced or replaced locally?

- ✓ Yes, All the materials and components required for this project are accessible locally, among which we can mention:

- * Iron profiles and plates

- * Electric motor with belt transmission or simple reducer

- * Spindle with jaws for small lathe

- * Bench grinder

- * Among others

- Required manufacturing processes can be povided locally?

- ✓ Yes

- No specialized knowledge or complex equipment is required to manufacture this lathe.

- Is specific training for manufacturing necessary and can be provided?

- ✓ Yes

- The people to develop the project must have solid knowledge in machining processes.

- Do all materials and processes meet the sustainability criteria?

- ✓ Yes

- The product and its production process can be considered as sustainable

2 Market analisis and requirements Functional and quantitative requirements

Functional and quantitative requirements

- Analysis of the current products on the market:

- VEVOR Mini Metal Lathe, 7"x14" Benchtop Metal Lathe, 550W Variable Speed 2250 rpm Metal Lathe, with 3-jaw Chuck Mini Lathe Machine, Precision Mini Lathe w/Tool Box Digital Display for Metal Turning

- * Price [USD]: 599

- * Source: amazon

- * Country: USA

- * Machine condition: New

- * Distance between centers [mm]: 350 (14")

- * Center height [mm]: 180 (7")

- * Spindle bore [mm]: 21

- * Cuck diameter [mm]: 80

- * Power [W]: 550

- * Speed [rpm]: 50 - 2250

- Proxxon 24002 Precision Lathe PD 250/E

- * Price [USD]: 1230

- * Source: ebay

- * Country: USA

- * Machine condition: New

- * Distance between centers [mm]: 250

- * Center height [mm]: 70

- * Spindle bore [mm]: 14

- * Cuck diameter [mm]: 70

- * Power [W]: 140

- * Speed [rpm]: 100 - 3000

- Grizzly Industrial G8688-7" x 12" Mini Metal Lathe

- * Price [USD]: 1180

- * Source: amazon

- * Country: USA

- * Machine condition: New

- * Distance between centers [in]: 12

- * Center height [in]: 7

- * Spindle bore [mm]: 20

- * Cuck diameter [in]: 6 1/4

- * Power [hp]: 1/3

- * Speed [rpm]: 100 - 2500

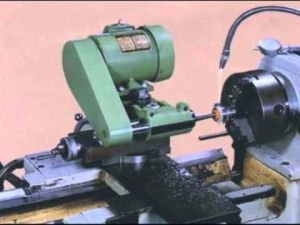

- Grizzly T27400 - 3/4 HP Tool Post Grinder

- * Price [USD]: 1495

- * Source: amazon

- * Country: USA

- * Machine condition: New

- * Power [hp]: 3/4

- * Inner wheel: 3/4*3/4", 60-grit

- * Outer wheel: 6*3/4", 60-grit

- * Speed[rpm]: 4500(external), 18500(internal)

- * This item is included as a reference for the commercial accessory necessary in the cylindrical grinding process on a lathe

- Requirements definition

Definition of the main technical data:

- Distance between centers [mm]: 350-400

- Center height [mm]: 200

- Spindle hole [mm]: 30

- Power on lathe [W]: 400-800

- Grinding power [W]: 600-1000

- Max Grinding Speed [rpm]: 3000-3600

- Expected tolerance [mm]: 0.1 (DIY equipment, limit values)

- These are reference values, based on commercial equipments and accessories.

- Optimal functions and features

Definition of necessary/optional functions and features:

- Cutting medium: bench grinder (initial premise)

- Tailstock: Mandatory

- Cross slide with turret for the grinding device: Mandatory

3 Search & analisis DIY technologies

The best technical solutions for all parts and components

- Customization of the OHO search engine

- To search for cases in our repository, the category classifier was used for metalworking lathes.

- Manual search in Google, Youtube, special websites etc.

- * Title: Building a lathe from industrial scrap

- * Views/likes/comments: 2461867/31689/1219

- * Engine power: 3hp

- * Chuck Diameter: 130mm

- * Size: 1000*400mm

- * Displacements: Square linear rail guide

- * Feed: ACME pitch 4mm

- * Additional comment: Manufactured in a machining workshop, oversized motor

- * Title: Homemade Lathe Machines

- * Views/likes/comments: 154978/2100/129

- * Distance between rails: 160mm

- * Rails length: 900mm

- * Feed: Rack with gear

- * Displacements: Rails and skids fabricated with an angle of 1"

- * Chuck diameter: 150 - 170 mm

- * Additional comment: Case mostly with qualitative information on the process

- * Title: Homemade Lathe Machine Full Episode.

- * Views/likes/comments: 721344/6575/194

- * Feed: Low grade threaded bar

- * Displacements: Round iron bars, inside iron pipes (no bushing)

- * Chuck diameter: 100 - 120 mm (DIY manufactured)

- * Additional comment: Less precision in the process in general. Case mostly with qualitative information on the process.

- * Title: DIY lathe on metal made from scrap

- * Views/likes/comments: 1200000/10430/176

- * Main motor: 1.1 kw

- * Velocity: 1400 rpm

- * Chuck diameter: 125 mm

- * Structure: Skeleton at 1 1/2" angles

- * Bench: UPN200 profile, 200*800 mm

- * Rails: Iron angle 1 1/2"

- * Feed: Low grade threaded bar

- * Additional comment: It will be taken as a reference machine for aspects such as the structure, the bench and some construction details.

- * Title: Homemade Lathe Machine

- * Views/likes/comments: 27734994/204398/6115

- * Chuck diameter: 125 mm

- * Structure: 2 U profiles of 4", plates between 10 and 70 mm

- * Bench: 200*1100mm including the chuck

- * Rails: Round with linear bearings blocks

- * Feed: Special helical profile

- * Estimated precision: 0.05 mm

- * Investment: 600 USD

- * Additional comment: Good stability in the rotation of the head, the set of rails, linear bearings and helical profile increase the cost of the project.

- * Title: Heavy duty Homemade Lathe

- * Views/likes/comments: 3011094/53503/4181

- * Estimated precision: 0.1 mm

- * Investment: 800 USD, 200 hrs

- * Additional comment: Case mostly with qualitative information on the process.

- * Title: My homemade tool post grinder

- * Views/likes/comments: 26708/315/34

- * Tool post grinder attachment

- * Three-phase motor, 135W, 1350 rpm

- * Transmission: belt ~1:5

- * Spindle with collet ER-16

- * External grinding wheel: ~4"

4 Development and documentation

Plans and specifications of all parts and components

- Analisis of functions & structures

- Analysis of functions, assemblies and components

- A review of the most important technical aspects in the design of this equipment was carried out, managing to identify and select its components, as well as its operating principles

- It should be noted that the analysis was made by combining cases of initiatives on metal lathes and cases of tool post grinder, since no DIY reference was found that performs both functions (cylindrical grinding).

- Development of technical solutions for assemblies and parts

- A review of the different options adopted in the DIY machines was carried out to meet each design requirement, observing the following variants for some evaluated details:

- * Evaluated detail: Lathe motor

- * Evaluated detail: Cutting medium

-

-

Rotary stone with motor (cylindrical grinding)

-

-

- * Evaluated detail: Bed and cross slide displacement

-

Linear bearings and helical profile

-

Iron metal profiles (angle)

-

Slides with round bars and guide tubes

- * Evaluated detail: Workpiece clamping

- * Evaluated detail: Free end centering

- See related comments: Discussion

- Creation of plans, parts lists, assembly instructions

- Currently the plans, CAD files, and others, are in their initial phase of preparation

- Peer-Reviews by the community, team members, experts etc.

- Among some revised and improved aspects of the project, prior to the publication of the plans, we can mention:

- * The grinding process with abrasives is not very well known, so the team turned to some theoretical and practical sources, such as Creep Feed, this being a point that our peers suggested we address based on tests, since there is not much information in the average small machine workshops.

- * Even so, the challenge of moving forward with the project was assumed, since, according to the testimony of the peers, it is worth having a small lathe, even if it is of low precision, for applications that are not very demanding, since it is an expensive service and scarce, and as already seen, according to initial estimates, there may be significant savings in cutting tools, as long as the production volume is not critical, with the use of abrasives for roughing.

- * Another outstanding point is achieving a minimum of precision in the equipment to be designed, since otherwise it would not be feasible, for which it is expected to work in the order of 0.1 mm, which can be useful in certain processes that will be seen in the discussions. This implies the need to consider aspects such as:

- - A robust bench

- - Rails with the best cost-precision ratio

- - Acquire certain components that, due to their complexity, should not be made in a workshop (chuck, tailstok mandrel, reasonable cost grinding mechanism...)

- - A resistant union in all the components, especially in the elements of transmission of power

5. Manufacturing, tests and improvements

To date, this project is on hold for manufacturing

- Workshop

Determination of the workshop for manufacturing:

- This project is considered as belonging to the group of Appropriate Technologies, for which it has been developed with the intention of the greatest possible access to processes and materials by the developers, with a basic, moderately equipped workshop, however, it is necessary also have the following facilities:

- * Tools and instruments for precision works in the order of 0.1 mm or less

- * Suitable equipment for cutting and welding thick parts (between 5 and 12 mm)

- * Adequate spaces, tools and equipment to carry out electrical work, in the case of the lathe drive motor and its electrical connections

- * Access to a turning and milling service for some parts that require machining

- Although these conditions do not pose a greater difficulty during manufacturing, it is left to the developer's discretion to choose between carrying out this work or requesting the services of a third party to guarantee a professional work

|