Difference between revisions of "Bench Vice"

From OHO - search engine for sustainable open hardware projects

(Created page with "{{Projekt |Images={{ProjektImages |projectimage=Oseg bv A BENCH VICE NF.png }}{{ProjektImages |projectimage=Oseg bv 1 SPINDLE NF.png }}{{ProjektImages |projectimage=Oseg bv 2...") |

|||

| (10 intermediate revisions by 4 users not shown) | |||

| Line 1: | Line 1: | ||

{{Projekt | {{Projekt | ||

|Images={{ProjektImages | |Images={{ProjektImages | ||

|projectimage=Bench Vice.png | |||

}}{{ProjektImages | |||

|projectimage=Oseg bv A BENCH VICE NF.png | |projectimage=Oseg bv A BENCH VICE NF.png | ||

}}{{ProjektImages | }}{{ProjektImages | ||

| Line 17: | Line 19: | ||

|kewords=bench vice press wokshop metal work | |kewords=bench vice press wokshop metal work | ||

|trans_status=MT | |trans_status=MT | ||

|desc=This is a simple model for a workshop bench vice without casting parts and made of simple, welded parts. It can be made in any simple locksmith's shop or metal workshop with simple equipment. You only need a drill, a metal saw and a welding machine to make it. It consists of two jaws, one of which is fixed and the other can be moved by a spindle. | |||

|licence=COHL12 | |licence=COHL12 | ||

|project_status=active | |project_status=active | ||

|design_files_pub=yes | |design_files_pub=yes | ||

|cad_files_editable=yes | |||

|mechanical_licence=COHL12 | |mechanical_licence=COHL12 | ||

|electronic_files_pub=no | |electronic_files_pub=no | ||

| Line 30: | Line 33: | ||

|contains_pdf_drawings=yes | |contains_pdf_drawings=yes | ||

|technology_readyness_level=2 | |technology_readyness_level=2 | ||

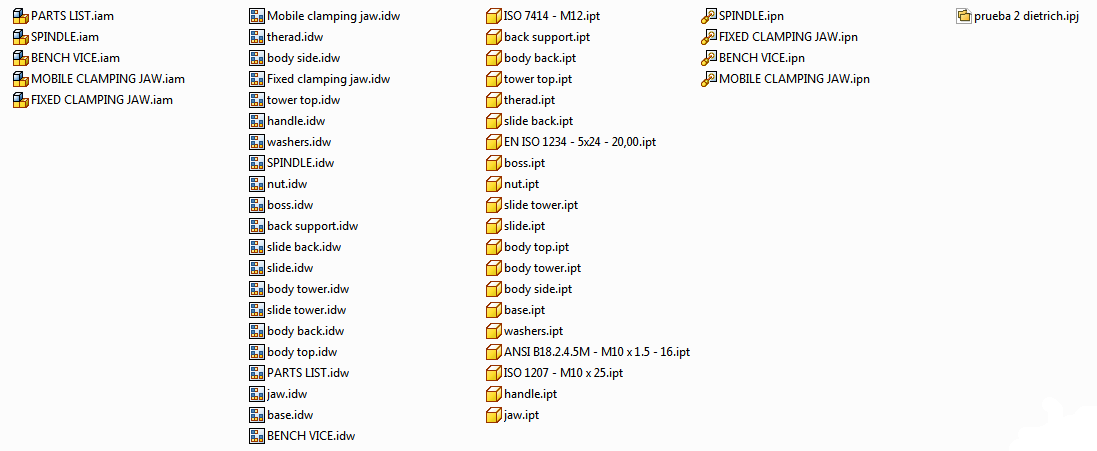

|TechDoc={{ProjektComponent | |||

|cmptitle=Bench Vice Cad Files | |||

|cmpimage=oseg_bv_cad1.png | |||

|cmpfile1=Inventor files.zip | |||

|cmpfile2=STEP.zip | |||

}}{{ProjektComponent | |||

|cmptitle=Banch Vice Complete PDF | |||

|cmpimage=oseg_bv_A BENCH VICE_NF.png | |||

|cmpfile1=Oseg bv bench-vice complete.pdf | |||

}} | |||

|Materials={{ProjektMaterials | |||

|matpartnumber=A | |||

|matdesc=Bench vice | |||

|matdrawingsheet=A | |||

|matpdffile=oseg_bv_A BENCH VICE.pdf | |||

|status_rev_1=approved | |||

}}{{ProjektMaterials | |||

|matpartnumber=B | |||

|matdesc=Parts list | |||

|matdrawingsheet=B | |||

|matpdffile=oseg_bv_B_part-list.pdf | |||

|status_rev_1=approved | |||

}}{{ProjektMaterials | |||

|matpartnumber=1 | |||

|matquantity=1 | |||

|matdesc=SPINDLE | |||

|matdrawingsheet=1 | |||

|matpdffile=oseg_bv_1 SPINDLE.pdf | |||

|status_rev_1=approved | |||

}}{{ProjektMaterials | |||

|matpartnumber=1.1 | |||

|matquantity=1 | |||

|matdesc=THERAD | |||

|matdrawingsheet=1.1 | |||

|matparttype=production | |||

|matspec=steel C45 | |||

|matpdffile=oseg_bv_1.1 therad.pdf | |||

|status_rev_1=approved | |||

}}{{ProjektMaterials | |||

|matpartnumber=1.2 | |||

|matquantity=1 | |||

|matdesc=BOSS | |||

|matdrawingsheet=1.2 | |||

|matparttype=production | |||

|matspec=steel C45 | |||

|matpdffile=oseg_bv_1.2 boss.pdf | |||

|status_rev_1=approved | |||

}}{{ProjektMaterials | |||

|matpartnumber=1.3 | |||

|matquantity=1 | |||

|matdesc=HANDLE | |||

|matdrawingsheet=1.3 | |||

|matparttype=production | |||

|matspec=steel C45 | |||

|matpdffile=oseg_bv_1.3 handle.pdf | |||

|status_rev_1=approved | |||

}}{{ProjektMaterials | |||

|matpartnumber=1.4 | |||

|matquantity=2 | |||

|matdesc=WASHERS | |||

|matdrawingsheet=1.4 | |||

|matparttype=standard | |||

|status_rev_1=approved | |||

}}{{ProjektMaterials | |||

|matpartnumber=1.5 | |||

|matquantity=2 | |||

|matdesc=ISO 7414 - M12 | |||

|matdrawingsheet=1.5 | |||

|matparttype=standard | |||

|status_rev_1=approved | |||

}}{{ProjektMaterials | |||

|matpartnumber=1.6 | |||

|matquantity=2 | |||

|matdesc=SPLIT PIN | |||

|matdrawingsheet=1.6 | |||

|matparttype=standard | |||

|status_rev_1=approved | |||

}}{{ProjektMaterials | |||

|matpartnumber=2 | |||

|matquantity=1 | |||

|matdesc=MOBILE CLAMPING JAW | |||

|matdrawingsheet=2 | |||

|matpdffile=oseg_bv_2 Mobile clamping jaw.pdf | |||

|status_rev_1=approved | |||

}}{{ProjektMaterials | |||

|matpartnumber=2.1 | |||

|matquantity=1 | |||

|matdesc=JAW | |||

|matdrawingsheet=2.1 | |||

|matparttype=production | |||

|matspec=steel C45 | |||

|matpdffile=oseg_bv_2.1 jaw.pdf | |||

|status_rev_1=approved | |||

}}{{ProjektMaterials | |||

|matpartnumber=2.2 | |||

|matquantity=1 | |||

|matdesc=SLIDE TOWER | |||

|matdrawingsheet=2.2 | |||

|matparttype=production | |||

|matspec=steel C45 | |||

|matpdffile=oseg_bv_2.2 slide tower.pdf | |||

|status_rev_1=approved | |||

}}{{ProjektMaterials | |||

|matpartnumber=2.3 | |||

|matquantity=1 | |||

|matdesc=TOWER TOP | |||

|matdrawingsheet=2.3 | |||

|matparttype=production | |||

|matspec=steel C45 | |||

|matpdffile=Oseg bv 2.3 tower top.pdf | |||

|status_rev_1=approved | |||

}}{{ProjektMaterials | |||

|matpartnumber=2.4 | |||

|matquantity=1 | |||

|matdesc=SLIDE BACK | |||

|matdrawingsheet=2.4 | |||

|matparttype=production | |||

|matspec=steel C45 | |||

|matpdffile=oseg_bv_2.4 slide back.pdf | |||

|status_rev_1=approved | |||

}}{{ProjektMaterials | |||

|matpartnumber=2.5 | |||

|matquantity=2 | |||

|matdesc=HEX JAM NUT | |||

|matdrawingsheet=2.5 | |||

|matparttype=standard | |||

|status_rev_1=approved | |||

}}{{ProjektMaterials | |||

|matpartnumber=2.6 | |||

|matquantity=1 | |||

|matdesc=BACK SUPPORT | |||

|matdrawingsheet=2.6 | |||

|matparttype=production | |||

|matspec=steel C45 | |||

|matpdffile=oseg_bv_2.6 back support.pdf | |||

|status_rev_1=approved | |||

}}{{ProjektMaterials | |||

|matpartnumber=2.7 | |||

|matquantity=1 | |||

|matdesc=SLIDE | |||

|matdrawingsheet=2.7 | |||

|matparttype=production | |||

|matspec=steel C45 | |||

|matpdffile=oseg_bv_2.7 slide.pdf | |||

|status_rev_1=approved | |||

}}{{ProjektMaterials | |||

|matpartnumber=2.8 | |||

|matquantity=2 | |||

|matdesc=ISO 1207 - M10 x 25 | |||

|matdrawingsheet=2.8 | |||

|matparttype=standard | |||

|status_rev_1=approved | |||

}}{{ProjektMaterials | |||

|matpartnumber=3 | |||

|matquantity=1 | |||

|matdesc=FIXED CLAMPING JAW | |||

|matdrawingsheet=3 | |||

|matpdffile=oseg_bv_3 fixed clamping jaw.pdf | |||

|status_rev_1=approved | |||

}}{{ProjektMaterials | |||

|matpartnumber=3.1 | |||

|matquantity=1 | |||

|matdesc=BASE | |||

|matdrawingsheet=3.1 | |||

|matparttype=production | |||

|matspec=steel C45 | |||

|matpdffile=oseg_bv_3.1 base.pdf | |||

|status_rev_1=approved | |||

}}{{ProjektMaterials | |||

|matpartnumber=3.2 | |||

|matquantity=2 | |||

|matdesc=BODY SIDE | |||

|matdrawingsheet=3.2 | |||

|matparttype=production | |||

|matspec=steel C45 | |||

|matpdffile=oseg_bv_3.2 body side.pdf | |||

|status_rev_1=approved | |||

}}{{ProjektMaterials | |||

|matpartnumber=3.3 | |||

|matquantity=1 | |||

|matdesc=BODY TOP | |||

|matdrawingsheet=3.3 | |||

|matparttype=production | |||

|matspec=steel C45 | |||

|matpdffile=oseg_bv_3.3 body top.pdf | |||

|status_rev_1=approved | |||

}}{{ProjektMaterials | |||

|matpartnumber=3.4 | |||

|matquantity=1 | |||

|matdesc=NUT | |||

|matdrawingsheet=3.4 | |||

|matparttype=production | |||

|matspec=steel C45 | |||

|matpdffile=oseg_bv_3.4 nut.pdf | |||

|status_rev_1=approved | |||

}}{{ProjektMaterials | |||

|matpartnumber=3.5 | |||

|matquantity=1 | |||

|matdesc=BODY TOWER | |||

|matdrawingsheet=3.5 | |||

|matparttype=production | |||

|matspec=steel C45 | |||

|matpdffile=oseg_bv_3.5 body tower.pdf | |||

|status_rev_1=approved | |||

}}{{ProjektMaterials | |||

|matpartnumber=3.6 | |||

|matquantity=1 | |||

|matdesc=BODY BACK | |||

|matdrawingsheet=3.6 | |||

|matparttype=production | |||

|matspec=steel C45 | |||

|matpdffile=oseg_bv_3.6 body back.pdf | |||

|status_rev_1=approved | |||

}} | |||

|certificate_requested=No | |certificate_requested=No | ||

|certificate_status=in process | |||

}} | }} | ||

Latest revision as of 03:28, 20 January 2022

|

Bench Vice Basic Data Category: Screw clamps Keywords: bench vice press wokshop metal work License: CERN OHL v1.2 Project status: Active Certification status: In process Technical documentation

Contains PDF-drawings: Yes CAD files are editable: Yes Assembly instructions are published: No Bill of materials is published: Yes

yes no

|

|

Description

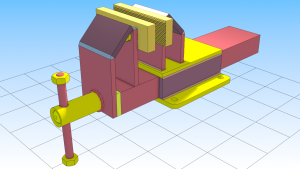

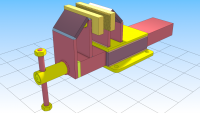

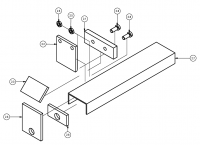

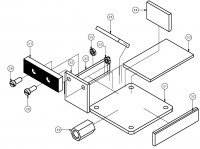

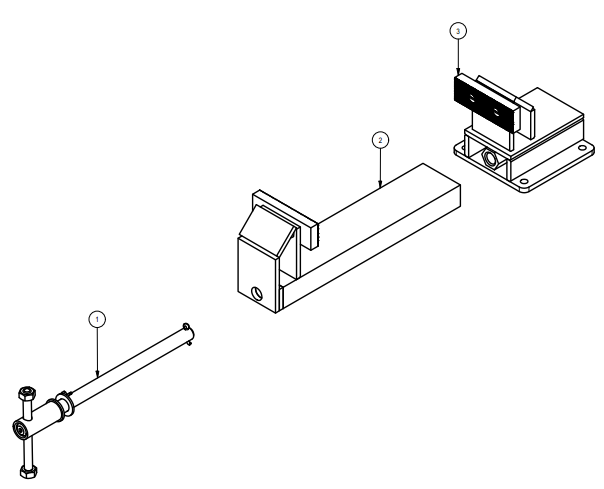

This is a simple model for a workshop bench vice without casting parts and made of simple, welded parts. It can be made in any simple locksmith's shop or metal workshop with simple equipment. You only need a drill, a metal saw and a welding machine to make it. It consists of two jaws, one of which is fixed and the other can be moved by a spindle.

Technical documentation

Bench Vice Cad Files | |

|

|

Files: | |

Banch Vice Complete PDF | |

|

|

Files: | |

+ General Reviews

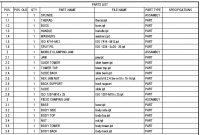

Parts list

| Pos. | Qty. | Part Name | Part code | Part Type | Specifications | Review Status | Show All Comments | |

|---|---|---|---|---|---|---|---|---|

| A | Bench vice | A |

REV1: Approved |

|||||

| B | Parts list | B |

REV1: Approved |

|||||

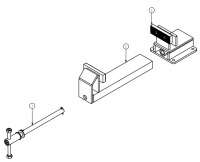

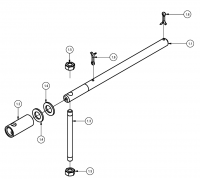

| 1 | 1 | SPINDLE | 1 |

REV1: Approved |

||||

| 1.1 | 1 | THERAD | 1.1 | Production | steel C45 |

REV1: Approved |

||

| 1.2 | 1 | BOSS | 1.2 | Production | steel C45 |

REV1: Approved |

||

| 1.3 | 1 | HANDLE | 1.3 | Production | steel C45 |

REV1: Approved |

||

| 1.4 | 2 | WASHERS | 1.4 | Standard |

REV1: Approved |

|||

| 1.5 | 2 | ISO 7414 - M12 | 1.5 | Standard |

REV1: Approved |

|||

| 1.6 | 2 | SPLIT PIN | 1.6 | Standard |

REV1: Approved |

|||

| 2 | 1 | MOBILE CLAMPING JAW | 2 |

REV1: Approved |

||||

| 2.1 | 1 | JAW | 2.1 | Production | steel C45 |

REV1: Approved |

||

| 2.2 | 1 | SLIDE TOWER | 2.2 | Production | steel C45 |

REV1: Approved |

||

| 2.3 | 1 | TOWER TOP | 2.3 | Production | steel C45 |

REV1: Approved |

||

| 2.4 | 1 | SLIDE BACK | 2.4 | Production | steel C45 |

REV1: Approved |

||

| 2.5 | 2 | HEX JAM NUT | 2.5 | Standard |

REV1: Approved |

|||

| 2.6 | 1 | BACK SUPPORT | 2.6 | Production | steel C45 |

REV1: Approved |

||

| 2.7 | 1 | SLIDE | 2.7 | Production | steel C45 |

REV1: Approved |

||

| 2.8 | 2 | ISO 1207 - M10 x 25 | 2.8 | Standard |

REV1: Approved |

|||

| 3 | 1 | FIXED CLAMPING JAW | 3 |

REV1: Approved |

||||

| 3.1 | 1 | BASE | 3.1 | Production | steel C45 |

REV1: Approved |

||

| 3.2 | 2 | BODY SIDE | 3.2 | Production | steel C45 |

REV1: Approved |

||

| 3.3 | 1 | BODY TOP | 3.3 | Production | steel C45 |

REV1: Approved |

||

| 3.4 | 1 | NUT | 3.4 | Production | steel C45 |

REV1: Approved |

||

| 3.5 | 1 | BODY TOWER | 3.5 | Production | steel C45 |

REV1: Approved |

||

| 3.6 | 1 | BODY BACK | 3.6 | Production | steel C45 |

REV1: Approved |

||