Difference between revisions of "Workshop Crane powered by drill"

Inddigital (talk | contribs) ((by SublimeText.Mediawiker)) |

|||

| (14 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

{{ | {{Projekt2 | ||

|Images={{ProjektImages | |Images= | ||

{{ProjektImages | |||

|projectimage=25-11-20 09-37-10 a.m..jpg | |||

}} | |||

{{ProjektImages | |||

|projectimage=Workshop Crane powered .png | |projectimage=Workshop Crane powered .png | ||

}}{{ProjektImages | }} | ||

<!-- {{ProjektImages | |||

|projectimage=Oseg wc A1 workshop-crane 000.jpg | |projectimage=Oseg wc A1 workshop-crane 000.jpg | ||

}}{{ProjektImages | }} --> | ||

{{ProjektImages | |||

|projectimage=Oseg wc A1 workshop-crane 001.jpg | |projectimage=Oseg wc A1 workshop-crane 001.jpg | ||

}}{{ProjektImages | }} | ||

|projectimage= | {{ProjektImages | ||

}}{{ProjektImages | |projectimage=oho_wc_Workshop Crane powered by DRILL 11-28 screenshot.png | ||

}} | |||

{{ProjektImages | |||

|projectimage=oho_wc_Workshop Crane powered by DRILL 11-43 screenshot.png | |||

}} | |||

{{ProjektImages | |||

|projectimage=oho_wc_Workshop Crane powered by DRILL 11-45 screenshot.png | |||

}} | |||

{{ProjektImages | |||

|projectimage=oseg_wc_Workshop Crane powered by DRILL 11-16 screenshot.png | |||

}} | |||

{{ProjektImages | |||

|projectimage=oseg_wc_Workshop Crane powered by DRILL 11-19 screenshot.png | |||

}} | |||

{{ProjektImages | |||

|projectimage=Oseg wc A2 workshop-crane 001.jpg | |projectimage=Oseg wc A2 workshop-crane 001.jpg | ||

}}{{ProjektImages | }} | ||

{{ProjektImages | |||

|projectimage=Oseg wc B1-B2 part-list 001.jpg | |projectimage=Oseg wc B1-B2 part-list 001.jpg | ||

}}{{ProjektImages | }} | ||

{{ProjektImages | |||

|projectimage=Oseg wc B1-B2 part-list 002.jpg | |projectimage=Oseg wc B1-B2 part-list 002.jpg | ||

}}{{ProjektImages | }} | ||

{{ProjektImages | |||

|projectimage=Oseg wc 1.0 main-frame 001.jpg | |projectimage=Oseg wc 1.0 main-frame 001.jpg | ||

}}{{ProjektImages | }} | ||

{{ProjektImages | |||

|projectimage=Oseg wc 1.0 main-frame 002.jpg | |projectimage=Oseg wc 1.0 main-frame 002.jpg | ||

}}{{ProjektImages | }} | ||

{{ProjektImages | |||

|projectimage=Oseg wc 2.0 pivot-arm 001.jpg | |projectimage=Oseg wc 2.0 pivot-arm 001.jpg | ||

}}{{ProjektImages | }} | ||

{{ProjektImages | |||

|projectimage=Oseg wc 3.0 telescopic-tube 001.jpg | |projectimage=Oseg wc 3.0 telescopic-tube 001.jpg | ||

}}{{ProjektImages | }} | ||

{{ProjektImages | |||

|projectimage=Oseg wc 4.0 left-leg 001.jpg | |projectimage=Oseg wc 4.0 left-leg 001.jpg | ||

}}{{ProjektImages | }} | ||

{{ProjektImages | |||

|projectimage=Oseg wc 5.0 right-leg 001.jpg | |projectimage=Oseg wc 5.0 right-leg 001.jpg | ||

}}{{ProjektImages | }} | ||

{{ProjektImages | |||

|projectimage=Oseg wc 6.0 arm 001.jpg | |projectimage=Oseg wc 6.0 arm 001.jpg | ||

}} | }} | ||

| Line 33: | Line 62: | ||

|projectnameES=Grúa de taller impulsada por taladro | |projectnameES=Grúa de taller impulsada por taladro | ||

|projectnameDE=Bohrgetriebener Werkstattkran | |projectnameDE=Bohrgetriebener Werkstattkran | ||

|kewords=workshop, crane, diy, drill, reverse engneering, drawings, measure, 3d, perspective, match, image, parametric | |kewords=workshop, crane, diy, drill, reverse engneering, drawings, measure, 3d, perspective, match, image, parametric, modelling, analysis | ||

|firstin=https://www.youtube.com/watch?v=-okGzH4Ur_c | |firstin=https://www.youtube.com/watch?v=-okGzH4Ur_c | ||

|trans_status=MT | |trans_status=MT | ||

|licence=CCBYSA40 | |licence=CCBYSA40 | ||

|typeproject=Youtube | |typeproject=Youtube | ||

| Line 55: | Line 80: | ||

|versioning_system=yes | |versioning_system=yes | ||

|contains_pdf_drawings=yes | |contains_pdf_drawings=yes | ||

|technology_readyness_level= | |technology_readyness_level=6 | ||

|TechDoc={{ | |Desc= | ||

{{ProjektComponent2 | |||

|cmptitle=Description | |||

|cmpimage=25-11-20_09-37-10_a.m..jpg | |||

|cmpimg= | |||

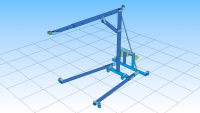

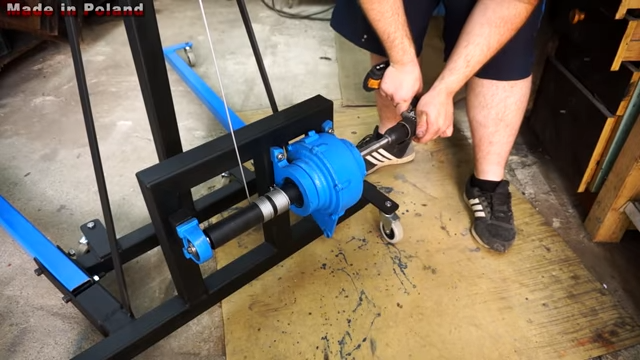

<p>Workshop crane powered by a hand drill | |||

Based on a video, the necessary parameters were determined to build the equipment in a professional way. | |||

Several tools were used such as perspective photo adjustment, anthropometric data to process images where people interact, mechanical resistance analysis, among others.</p> | |||

<p>This project is published under the terms of the CC-BY-SA 4.0</p> | |||

<!-- Reference: https://www.youtube.com/watch?v=FGPVdLr42Yg --> | |||

}} | |||

<div style="margin:20px"></div> | |||

{{ProjektComponent2 | |||

|cmptitle= Technical data | |||

|cmpimg= | |||

<div> | |||

<table width="100%" style="border: solid 1px !important;"> | |||

<tr style="visibility: collapse;"> | |||

<td width='50%'></td> | |||

<td width='50%'></td> | |||

</tr> | |||

<tr style="border: solid 1px !important;"> | |||

<th style="display: table-cell;"> Feature | |||

</th> | |||

<th style="display: table-cell;"> Detail | |||

</th> | |||

</tr> | |||

<tr> | |||

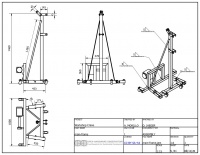

<td style="display: table-cell;"> General dimensions | |||

</td> | |||

<td style="display: table-cell;"> 2.1 m (L) x 1.2 m (W) x 1.4 m (H) | |||

</td> | |||

</tr> | |||

<tr> | |||

<td style="display: table-cell;"> Load capacity | |||

</td> | |||

<td style="display: table-cell;"> 200 kg, estimated by the manufacturer, may be more | |||

</td> | |||

</tr> | |||

<tr> | |||

<td style="display: table-cell;"> Reducer ratio | |||

</td> | |||

<td style="display: table-cell;"> 1:100 | |||

</td> | |||

</tr> | |||

<tr> | |||

<td style="display: table-cell;"> Wheel material | |||

</td> | |||

<td style="display: table-cell;"> Plastic, can be metallic | |||

</td> | |||

</tr> | |||

<tr> | |||

<td style="display: table-cell;"> Material construction | |||

</td> | |||

<td style="display: table-cell;"> 60x60x4 mm structural steel tube | |||

</td> | |||

</tr> | |||

<tr> | |||

<td style="display: table-cell;"> Other features | |||

</td> | |||

<td style="display: table-cell;"> | |||

<ul> | |||

<li>Modular design, collapsible for storage</li> | |||

<li>Adjustable arm extension, varies up to 465 mm</li> | |||

</ul> | |||

</td> | |||

</tr> | |||

</table> | |||

</div> | |||

}} | |||

|TechDoc={{ProjektComponent2 | |||

|cmptitle=Development Guide | |cmptitle=Development Guide | ||

|cmpimage=30-11-20 11-08-54 p.m..jpg | |cmpimage=30-11-20 11-08-54 p.m..jpg | ||

|cmpimg= | |||

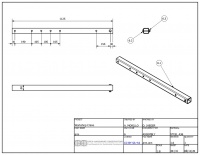

The design of the equipment involved several analyses, including perspective photo adjustment, anthropometric data processing, and mechanical resistance analysis. Perspective photo adjustment is used to ensure that the crane is designed accurately based on the perspective of the image. Anthropometric data processing is used to determine the appropriate size and dimensions of the crane based on human measurements among other factors like safety features, ease of use, and cost-effectiveness. | |||

|cmpfile1=Oseg wc Reverse-Engineerig-proces-para-Workshop-Crane-powered-by-DRILL 1-05.pdf | |cmpfile1=Oseg wc Reverse-Engineerig-proces-para-Workshop-Crane-powered-by-DRILL 1-05.pdf | ||

}}{{ | }} | ||

{{ProjektComponent2 | |||

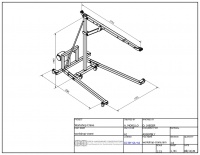

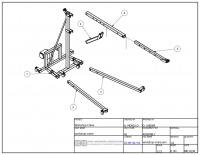

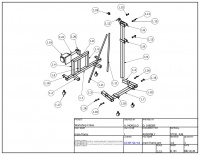

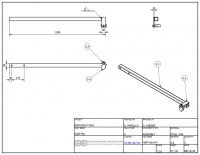

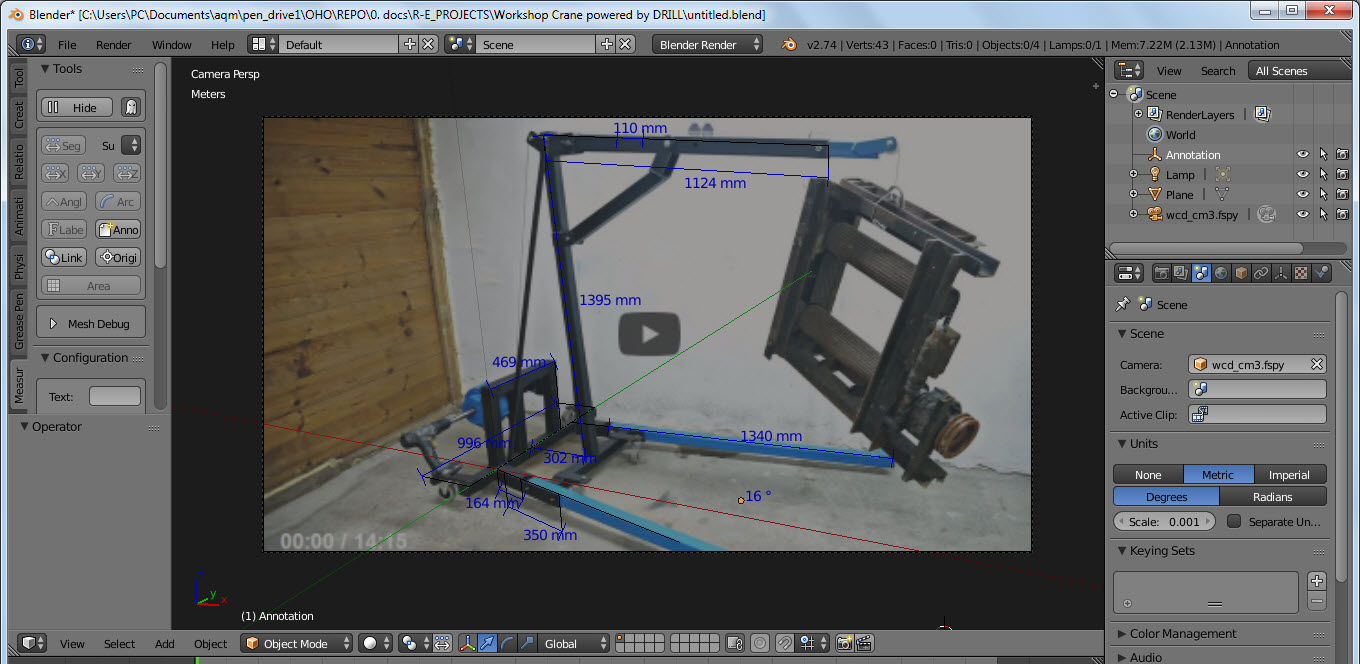

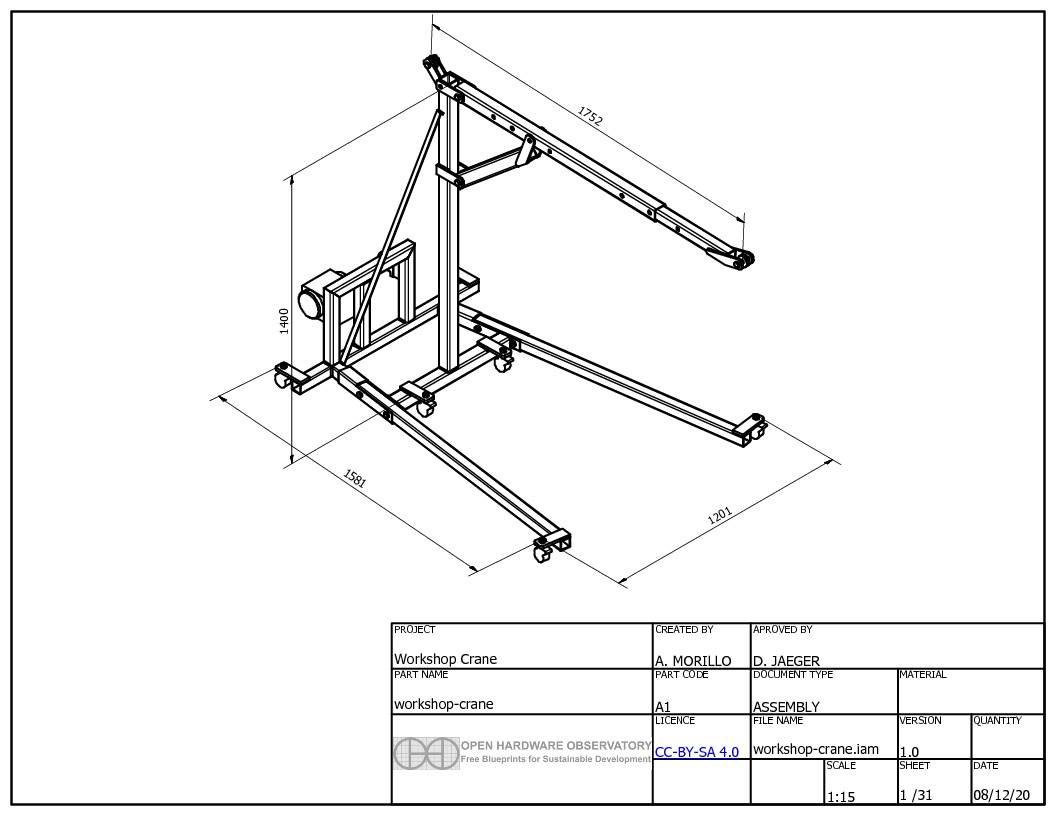

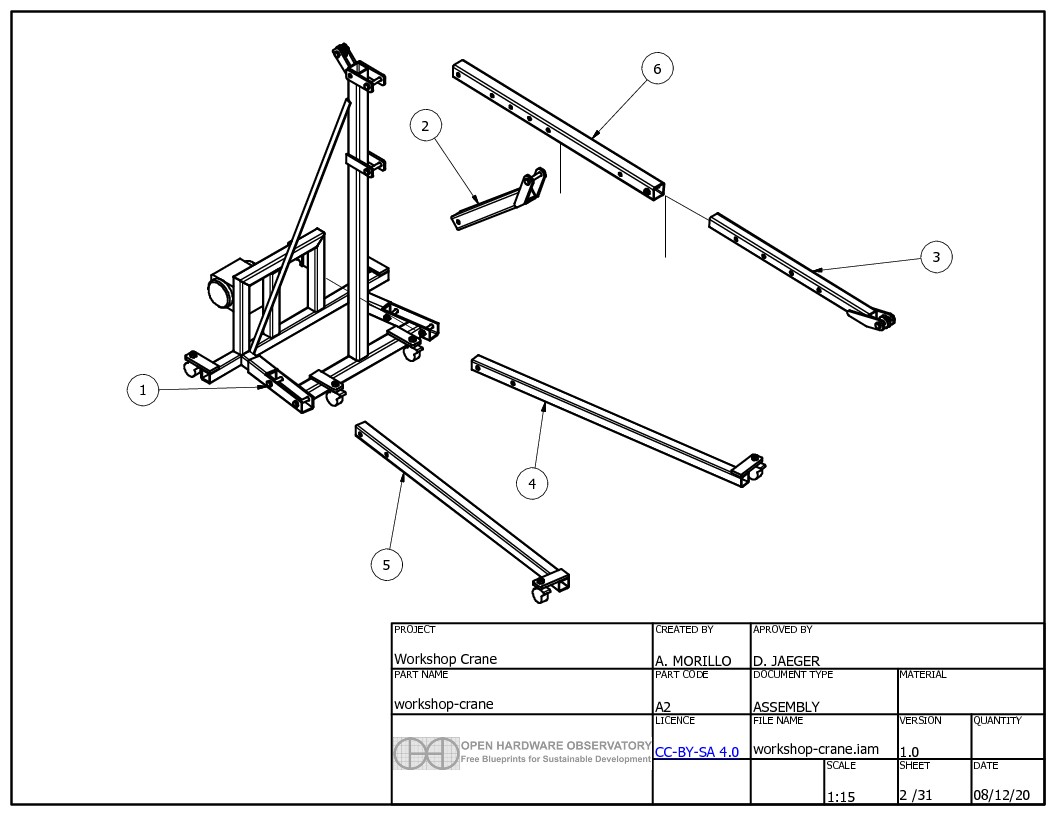

|cmptitle=PDF plans | |cmptitle=PDF plans | ||

|cmpimage=Oseg wc A1 workshop-crane 001.jpg | |cmpimage=Oseg wc A1 workshop-crane 001.jpg | ||

|cmpfile1=Oseg wc workshop-crane 1-02.pdf | |cmpfile1=Oseg wc workshop-crane 1-02.pdf | ||

}}{{ | }} | ||

{{ProjektComponent2 | |||

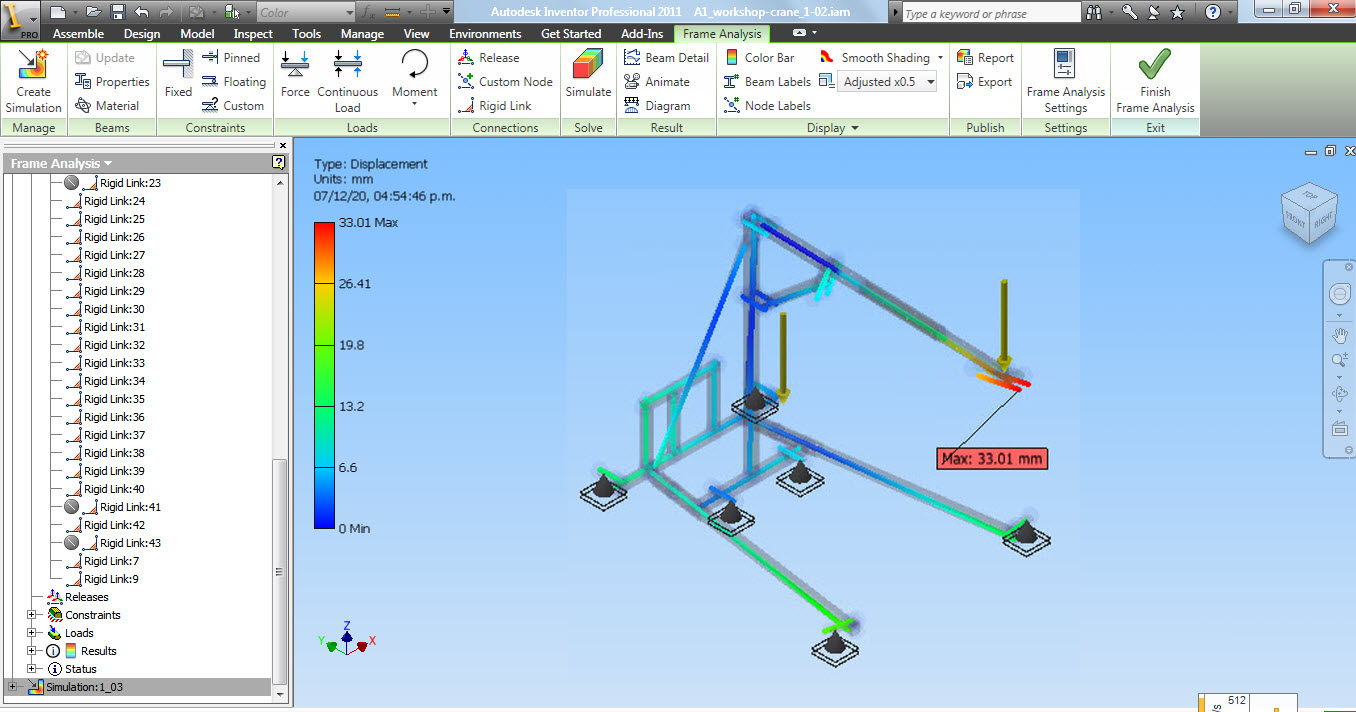

|cmptitle=Frame Analysis Report - example | |cmptitle=Frame Analysis Report - example | ||

|cmpimage=07-12-20 04-55-00 p.m..jpg | |cmpimage=07-12-20 04-55-00 p.m..jpg | ||

|cmpimg= | |||

Mechanical resistance analysis is used to ensure that the crane can withstand the weight and stress it will be subjected to during use. | |||

|cmpfile1=Workshop crane Frame Analysis Report.pdf | |cmpfile1=Workshop crane Frame Analysis Report.pdf | ||

}}{{ | }} | ||

{{ProjektComponent2 | |||

|cmptitle=CAD files | |cmptitle=CAD files | ||

|cmpimage=09-12-20 04-54-48 p.m..jpg | |cmpimage=09-12-20 04-54-48 p.m..jpg | ||

|cmpfile1=Oseg wc CAD-files 1-01.zip | |cmpfile1=Oseg wc CAD-files 1-01.zip | ||

|cmpfile2=Oseg wc step.zip | |cmpfile2=Oseg wc step.zip | ||

}}{{ | }} | ||

<!--{{ProjektComponent2 | |||

|cmptitle=Video | |cmptitle=Video | ||

|cmpfile1=workshop-crane B.mp4 | |cmpfile1=workshop-crane B.mp4 | ||

}}{{ | }} --> | ||

<div style="margin:20px"></div> | |||

{{ProjektComponent2 | |||

|cmptitle=Assembly instructions | |||

<!-- |cmpimage=oho-spe-test1.png --> | |||

|cmpimg= | |||

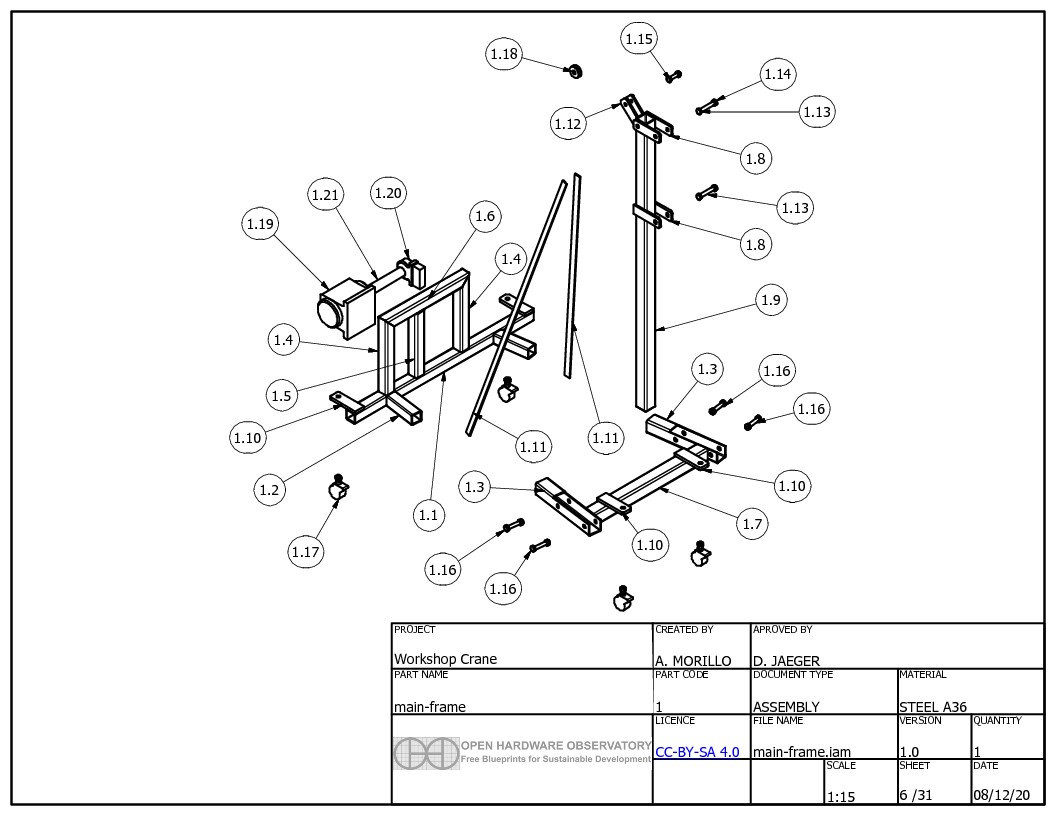

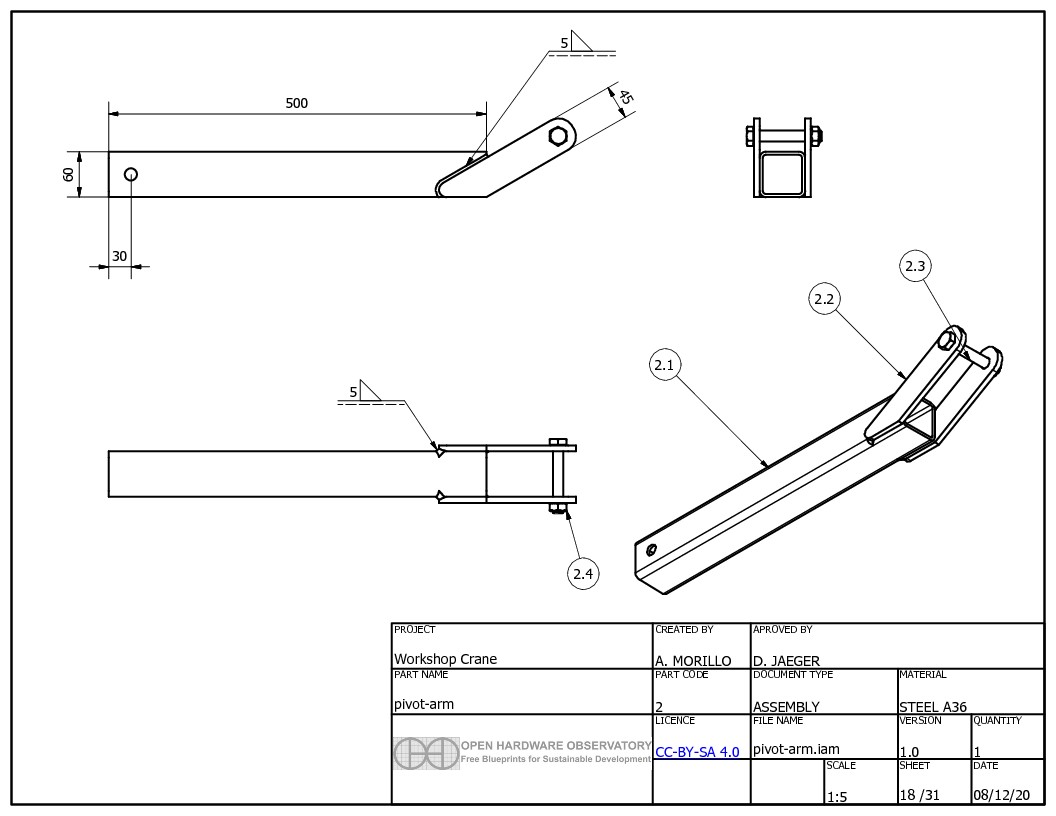

Here are some plans with the assembly sets and pieces. | |||

<!-- , which can be detailed at [https://www.youtube.com/watch?v=FGPVdLr42Yg this link] --> | |||

<div class="mw-collapsible" id="mw-customcollapsible-div1" data-origID="mw-customcollapsible-div1"> | |||

<div style="text-align:left;"> | |||

<i class="mw-customtoggle-div1" style="color:#1b599a;">Zoom in</i> | |||

</div> | |||

<div class="res-img col-auto col-sm-auto col-md-auto col-lg-5 col-xl-5"> | |||

[[File:Oseg_wc_A2_workshop-crane_001.jpg]] | |||

<div style="margin:20px"></div> | |||

[[File:Oseg_wc_1.0_main-frame_002.jpg]] | |||

<div style="margin:20px"></div> | |||

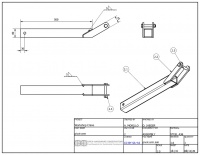

[[File:Oseg_wc_2.0_pivot-arm_001.jpg]] | |||

<div style="margin:20px"></div> | |||

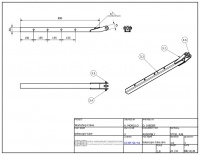

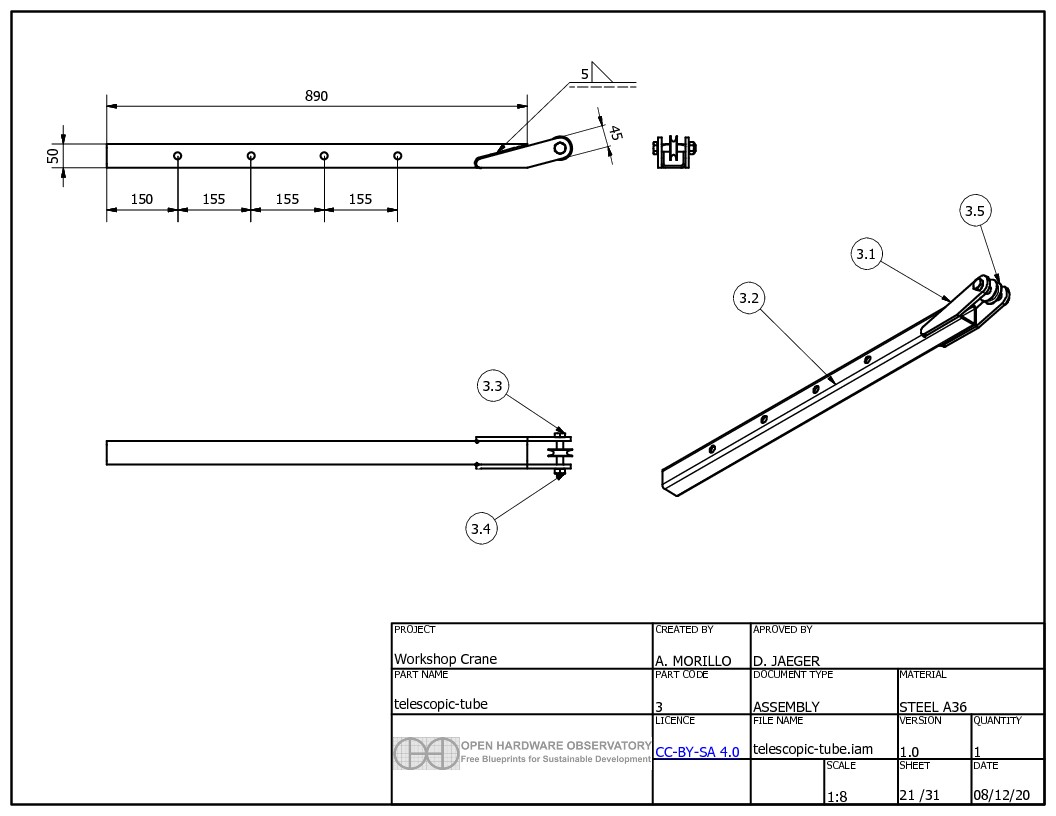

[[File:Oseg_wc_3.0_telescopic-tube_001.jpg]] | |||

<div style="margin:20px"></div> | |||

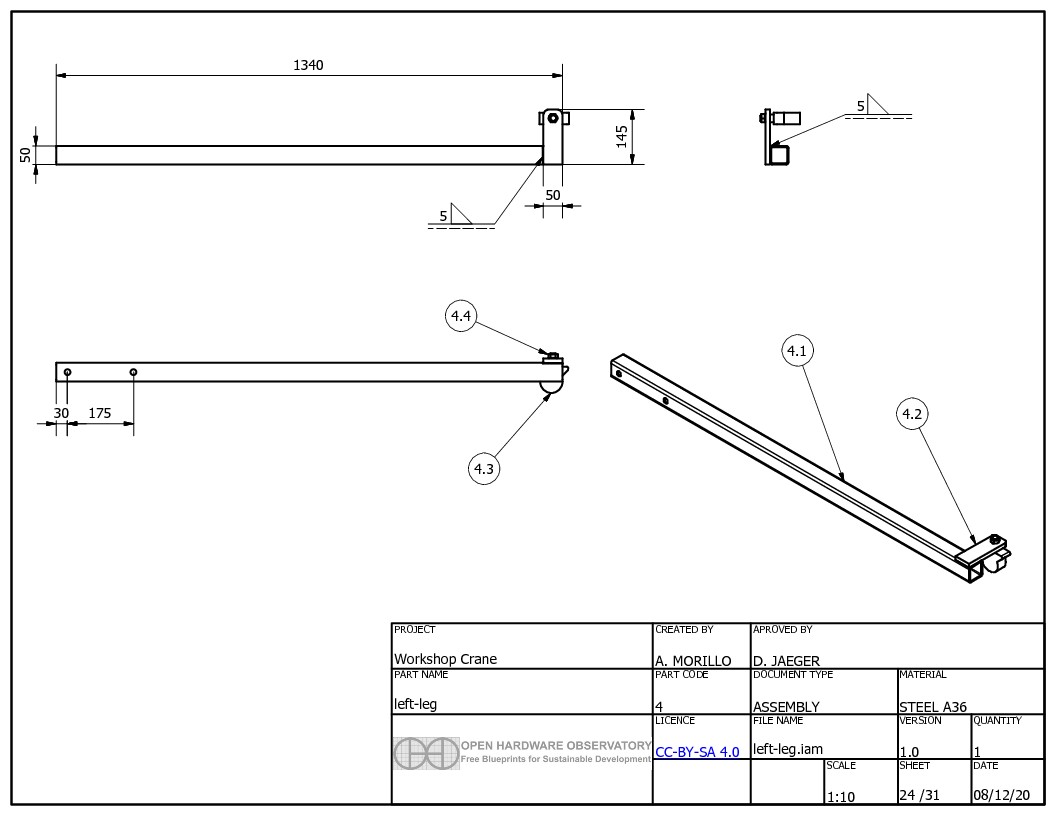

[[File:Oseg_wc_4.0_left-leg_001.jpg]] | |||

<div style="margin:20px"></div> | |||

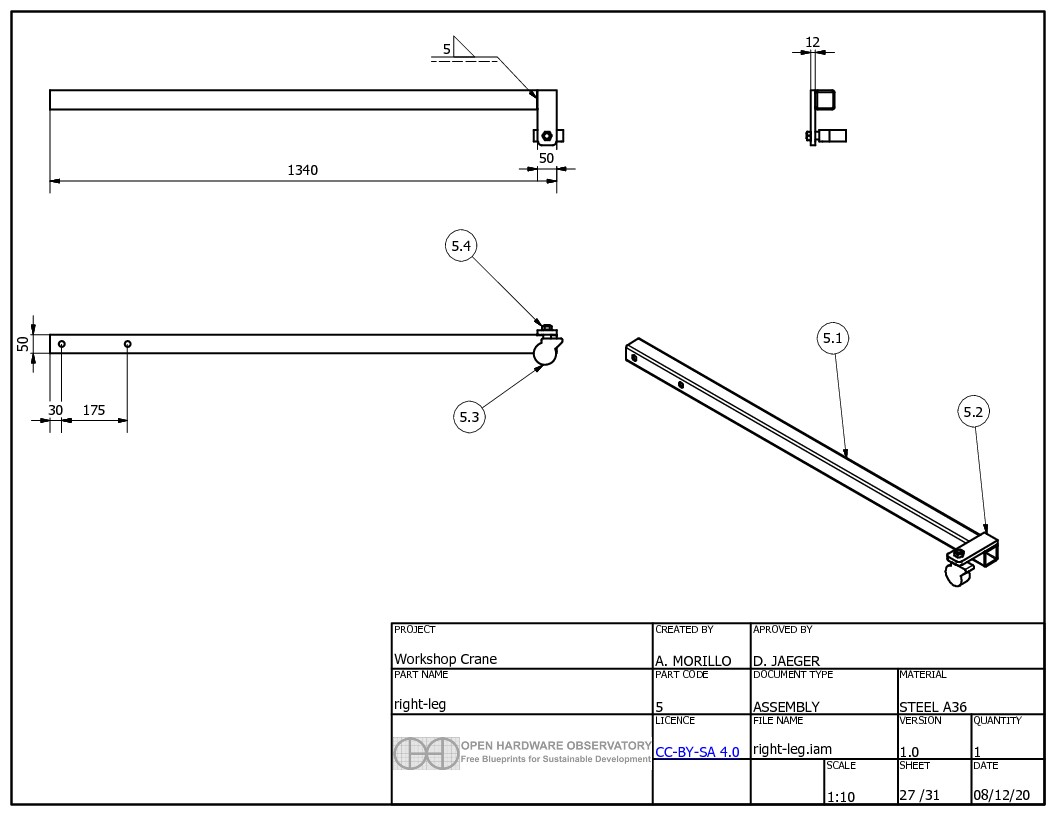

[[File:Oseg_wc_5.0_right-leg_001.jpg]] | |||

<div style="margin:20px"></div> | |||

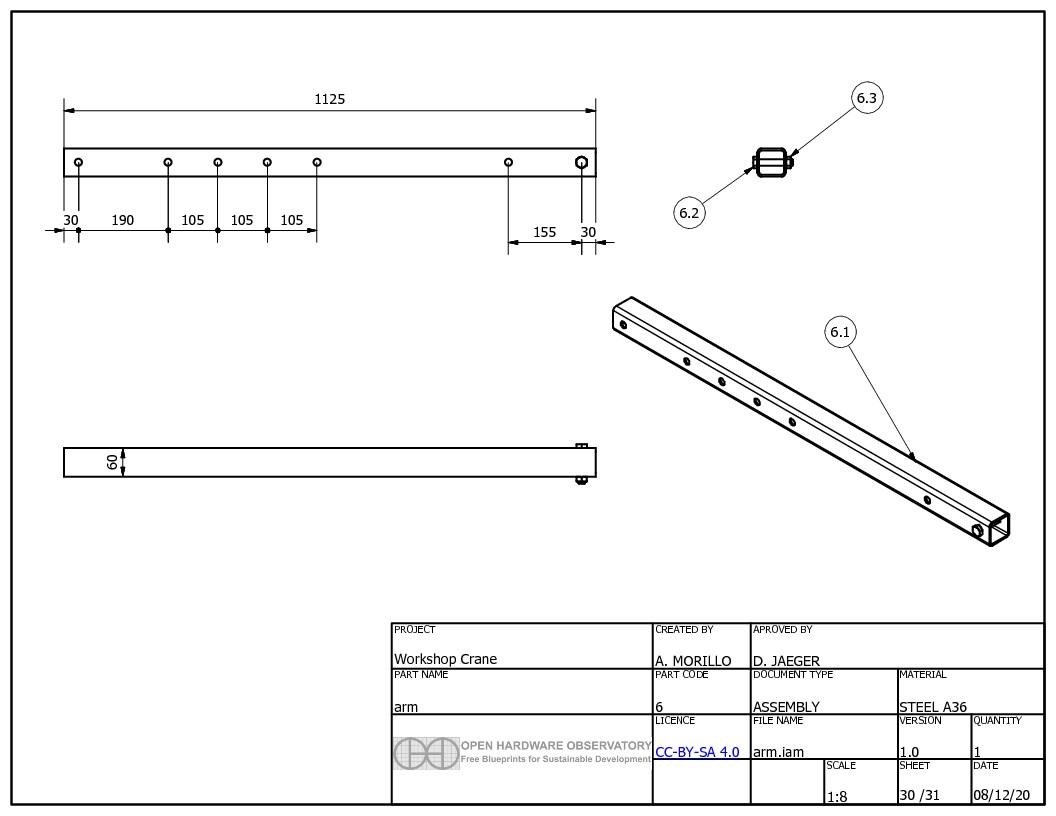

[[File:Oseg_wc_6.0_arm_001.jpg]] | |||

</div> | |||

</div> | |||

<div class="mw-collapsible mw-collapsed" id="mw-customcollapsible-div1" data-origID="mw-customcollapsible-div1"> | |||

<div style="text-align:left;;"> | |||

<i class="mw-customtoggle-div1" style="color:#1b599a;">Zoom out</i> | |||

</div> | |||

<div> | |||

[[File:Oseg_wc_A2_workshop-crane_001.jpg]] | |||

<div style="margin:20px"></div> | |||

[[File:Oseg_wc_1.0_main-frame_002.jpg]] | |||

<div style="margin:20px"></div> | |||

[[File:Oseg_wc_2.0_pivot-arm_001.jpg]] | |||

<div style="margin:20px"></div> | |||

[[File:Oseg_wc_3.0_telescopic-tube_001.jpg]] | |||

<div style="margin:20px"></div> | |||

[[File:Oseg_wc_4.0_left-leg_001.jpg]] | |||

<div style="margin:20px"></div> | |||

[[File:Oseg_wc_5.0_right-leg_001.jpg]] | |||

<div style="margin:20px"></div> | |||

[[File:Oseg_wc_6.0_arm_001.jpg]] | |||

</div> | |||

</div> | |||

On the original developer's video, you can see the manufacturing stages, you can access it at [https://www.youtube.com/watch?v=FGPVdLr42Yg this link] | |||

}} | |||

<div style="margin:20px"></div> | |||

{{ProjektComponent2 | |||

|cmptitle=Tests, practical applications | |||

|cmpimage=oseg_wc_Workshop Crane powered by DRILL 13-6 screenshot.png | |||

|cmpimg= | |||

The crane is put to the test after its manufacture, demonstrating its proper functioning for tasks in the workshop: | |||

* [https://youtu.be/FGPVdLr42Yg?t=722 Lifting a geared motor] | |||

* [https://youtu.be/FGPVdLr42Yg?t=767 Lifting a set of metal rollers] | |||

}} | |||

|Materials={{ProjektMaterials | |Materials={{ProjektMaterials | ||

|matpartnumber=A1 | |matpartnumber=A1 | ||

Latest revision as of 02:55, 18 April 2023

Project data

|

Category: Mobile cranes URL (first publication): https://www.youtube.com/watch?v=-okGzH4Ur_c Keywords: workshop, crane, diy, drill, reverse engneering, drawings, measure, 3d, perspective, match, image, parametric, modelling, analysis License: CC BY-SA 4.0 Project status: Active Certification status: Approved

Contains PDF-drawings: Yes CAD files are editable: Yes Assembly instructions are published: Yes Bill of materials is published: Yes

yes yes

|

Project details

Description

Workshop crane powered by a hand drill Based on a video, the necessary parameters were determined to build the equipment in a professional way. Several tools were used such as perspective photo adjustment, anthropometric data to process images where people interact, mechanical resistance analysis, among others.

This project is published under the terms of the CC-BY-SA 4.0

Technical data

| Feature | Detail |

|---|---|

| General dimensions | 2.1 m (L) x 1.2 m (W) x 1.4 m (H) |

| Load capacity | 200 kg, estimated by the manufacturer, may be more |

| Reducer ratio | 1:100 |

| Wheel material | Plastic, can be metallic |

| Material construction | 60x60x4 mm structural steel tube |

| Other features |

|

Technical documentation

Development Guide

The design of the equipment involved several analyses, including perspective photo adjustment, anthropometric data processing, and mechanical resistance analysis. Perspective photo adjustment is used to ensure that the crane is designed accurately based on the perspective of the image. Anthropometric data processing is used to determine the appropriate size and dimensions of the crane based on human measurements among other factors like safety features, ease of use, and cost-effectiveness.

Frame Analysis Report - example

Mechanical resistance analysis is used to ensure that the crane can withstand the weight and stress it will be subjected to during use.

Assembly instructions

Here are some plans with the assembly sets and pieces.

On the original developer's video, you can see the manufacturing stages, you can access it at this link

Tests, practical applications

The crane is put to the test after its manufacture, demonstrating its proper functioning for tasks in the workshop:

+ General Reviews

Reviews

| Pos. | Qty. | Part Name | Part code | Part Type | Specifications | Review Status | Show All Comments | |

|---|---|---|---|---|---|---|---|---|

| A1 | 1 | WORKSHOP CRANE | A1 |

REV1: Approved |

||||

| A2 | 1 | WORKSHOP CRANE | A2 | Standard |

REV1: Approved |

|||

| B1 | PART LIST | B |

REV1: Approved |

|||||

| 1 | 1 | Main Frame | 1 |

REV1: Approved |

||||

| 1.1 | 1 | Tube 50*50*4*1000 mm | 1.1 | Production | EN 10210-2, STEEL A36 |

REV1: Approved |

||

| 1.2 | 2 | Tube 50*50*4*172 mm | 1.2 | Production | EN 10210-2, STEEL A36 |

REV1: Approved |

||

| 1.3 | 1 | Tube 60*60*4*350 mm | 1.3 | Production | EN 10210-2, STEEL A36 |

REV1: Approved |

||

| 1.4 | 2 | Tube 50*50*4*360 mm | 1.4 | Production | EN 10210-2, STEEL A36 |

REV1: Approved |

||

| 1.5 | 1 | Tube 50*50*4*310 mm | 1.5 | Production | EN 10210-2, STEEL A36 |

REV1: Approved |

||

| 1.6 | 1 | Tube 50*50*4*470 mm | 1.6 | Production | EN 10210-2, STEEL A36 |

REV1: Approved |

||

| 1.7 | 1 | Tube 60*60*4*638 mm | 1.7 | Production | EN 10210-2, STEEL A36 |

REV1: Approved |

||

| 1.8 | 4 | flat steel bar 45*8*145 mm | 1.8 | Production | EN 10058, STEEL A36 |

REV1: Approved |

||

| 1.9 | 1 | Tube 60*60*4*1400 mm | 1.9 | Production | EN 10210-2, STEEL A36 |

REV1: Approved |

||

| 1.10 | 4 | flat steel bar 50*12*145 mm | 1.10 | Production | EN 10058, STEEL A36 |

REV1: Approved |

||

| 1.11 | 2 | flat steel bar 25*5*1308 mm | 1.11 | Production | EN 10058, STEEL A36 |

REV1: Approved |

||

| 1.12 | 2 | flat steel bar 45*8*135 mm | 1.12 | Production | EN 10058, STEEL A36 |

REV1: Approved |

||

| 1.13 | 2 | Hex-Head Bolt | 1.13 | Standard | DIN 931-1 - M14 x 90 |

REV1: Approved |

||

| 1.14 | 11 | Hex Nut | 1.14 | Standard | DIN 555-5 - M14 |

REV1: Approved |

||

| 1.15 | 1 | Hex-Head Bolt | 1.15 | Standard | DIN 931-1 - M14 x 55 |

REV1: Approved |

||

| 1.16 | 4 | Hex-Head Bolt | 1.16 | Standard | DIN 931-1 - M14 x 75 |

REV1: Approved |

||

| 1.17 | 4 | WHEEL | 1.17 | Buy | CAP 200 KG |

REV1: Approved |

||

| 1.18 | 1 | PULLEY | 1.18 | Buy | D 50 mm, CABLE 10 mm |

REV1: Approved |

||

| 1.19 | 1 | Reducer | 1.19 | Buy | i = 1:100, SECURITY BRAKE |

REV1: Approved |

||

| 1.20 | 1 | Bearing | 1.20 | Buy | DEPENDS ON ITEM 1.20 |

REV1: Approved |

||

| 1.21 | 1 | Hollow Shaft | 1.21 | Buy | DEPENDS ON ITEM 1.20 |

REV1: Approved |

||

| 2 | 1 | Pivot Arm | 2 |

REV1: Approved |

||||

| 2.1 | 1 | Tube 60*60*4*500 mm | 2.1 | Production | EN 10210-2, STEEL A36 |

REV1: Approved |

||

| 2.2 | 2 | flat steel bar 45*8*222 mm | 2.2 | Production | EN 10058, STEEL A36 |

REV1: Approved |

||

| 2.3 | 1 | Hex-Head Bolt | 2.3 | Standard | DIN 931-1 - M14 x 90 |

REV1: Approved |

||

| 2.4 | 1 | Hex Nut | 2.4 | Standard | DIN 555-5 - M14 |

REV1: Approved |

||

| 3 | 1 | Telescopic Tube | 3 |

REV1: Approved |

||||

| 3.1 | 2 | flat steel bar 45*8*267 mm | 3.1 | Production | EN 10058, STEEL A36 |

REV1: Approved |

||

| 3.2 | 1 | Tube 50*50*4*890 mm | 3.2 | Production | EN 10210-2, STEEL A36 |

REV1: Approved |

||

| 3.3 | 1 | Hex-Head Bolt | 3.3 | Standard | DIN 931-1 - M14 x 80 |

REV1: Approved |

||

| 3.4 | 1 | Hex Nut | 3.4 | Standard | DIN 555-5 - M14 |

REV1: Approved |

||

| 3.5 | 1 | PULLEY | 3.5 | Buy | D 50 mm, CABLE 10 mm |

REV1: Approved |

||

| 4 | 1 | Lef Leg | 4 |

REV1: Approved |

||||

| 4.1 | 1 | Tube 50*50*4*1340 mm | 4.1 | Production | EN 10210-2, STEEL A36 |

REV1: Approved |

||

| 4.2 | 1 | flat steel bar 50*12*145 mm | 4.2 | Production | EN 10058, STEEL A36 |

REV1: Approved |

||

| 4.3 | 1 | WHEEL | 4.3 | Buy | CAP 200 KG |

REV1: Approved |

||

| 4.4 | 1 | Hex Nut | 4.4 | Standard | DIN 555-5 - M14 |

REV1: Approved |

||

| 5 | 1 | Right Leg | 5 |

REV1: Approved |

||||

| 5.1 | 1 | Tube 50*50*4*1340 mm | 5.1 | Production | EN 10210-2, STEEL A36 |

REV1: Approved |

||

| 5.2 | 1 | flat steel bar 50*12*145 mm | 5.2 | Production | EN 10058, STEEL A36 |

REV1: Approved |

||

| 5.3 | 1 | WHEEL | 5.3 | Buy | CAP 200 KG |

REV1: Approved |

||

| 5.4 | 1 | Hex Nut | 5.4 | Standard | DIN 555-5 - M14 |

REV1: Approved |

||

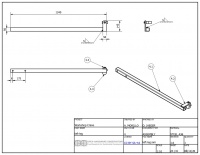

| 6 | 1 | Arm | 6 |

REV1: Approved |

||||

| 6.1 | 1 | Tube 60*60*4*1125 mm | 6.1 | Production | EN 10210-2, STEEL A36 |

REV1: Approved |

||

| 6.2 | 1 | Hex-Head Bolt | 6.2 | Standard | DIN 931-1 - M14 x 75 |

REV1: Approved |

||

| 6.3 | 1 | Hex Nut | 6.3 | Standard | DIN 555-5 - M14 |

REV1: Approved |

||