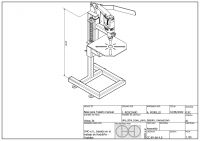

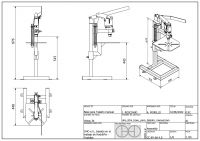

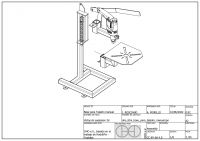

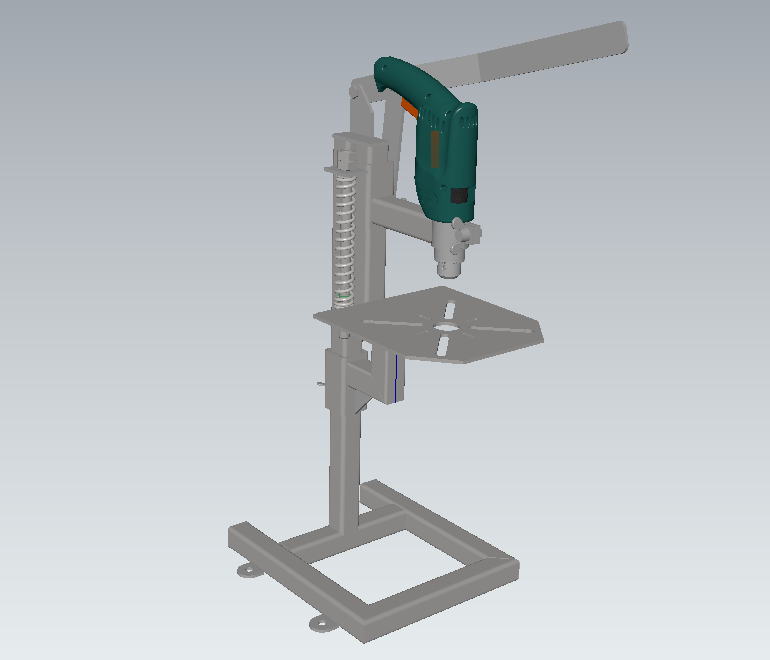

Stand for manual drill

Project data

|

Category: Bench drills URL (first publication): https://www.youtube.com/watch?v=LUPKzYBPz9Y Keywords: drill, stand, diy, metal, machine, workshop, open source, hole, drilling License: CC BY-SA 4.0 Organization: OHO Project status: Active

Maturity of the project: production / DIY

Contains PDF-drawings: Yes CAD files are editable: Yes Assembly instructions are published: Yes Bill of materials is published: Yes

yes yes

|

Project details

Description

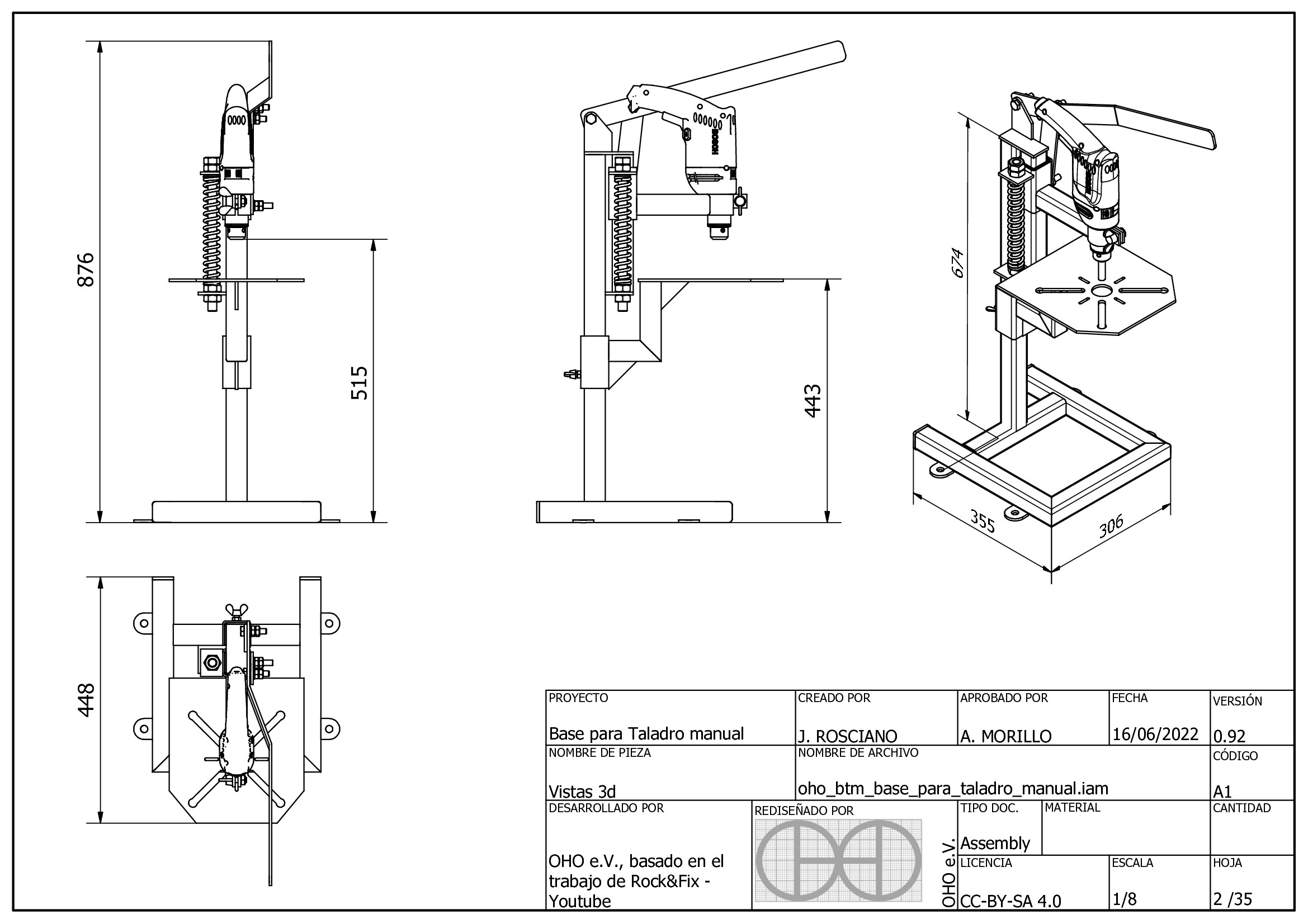

In this project, a DIY manual drill press base is developed, designed based on Rock and Fix homemade Youtube video that shows the construction process step by step. The base is made using accessible materials and common workshop tools, making it accessible and cost-effective for DIY enthusiasts. Detailed plans and precise measurements are provided so that users can easily replicate the design and obtain a functional and sturdy base for their manual drill, allowing them to carry out precise and safe drilling in their DIY projects.

Technical data

Based on the technical characteristics of some commercial equipment used in workshops, the following characteristics or requirements were extracted:

- Clamp diameter: 38-43mm

- Base size: 150-200mm

- Maximum clamp height: 250-350mm

- Drilling career: 150-170mm

- Leverage: 1:6

- Mobile platform in z axis: Yes, sliding

- Return Mechanism: Yes, compression spring

- Feed stop: Yes

Technical documentation

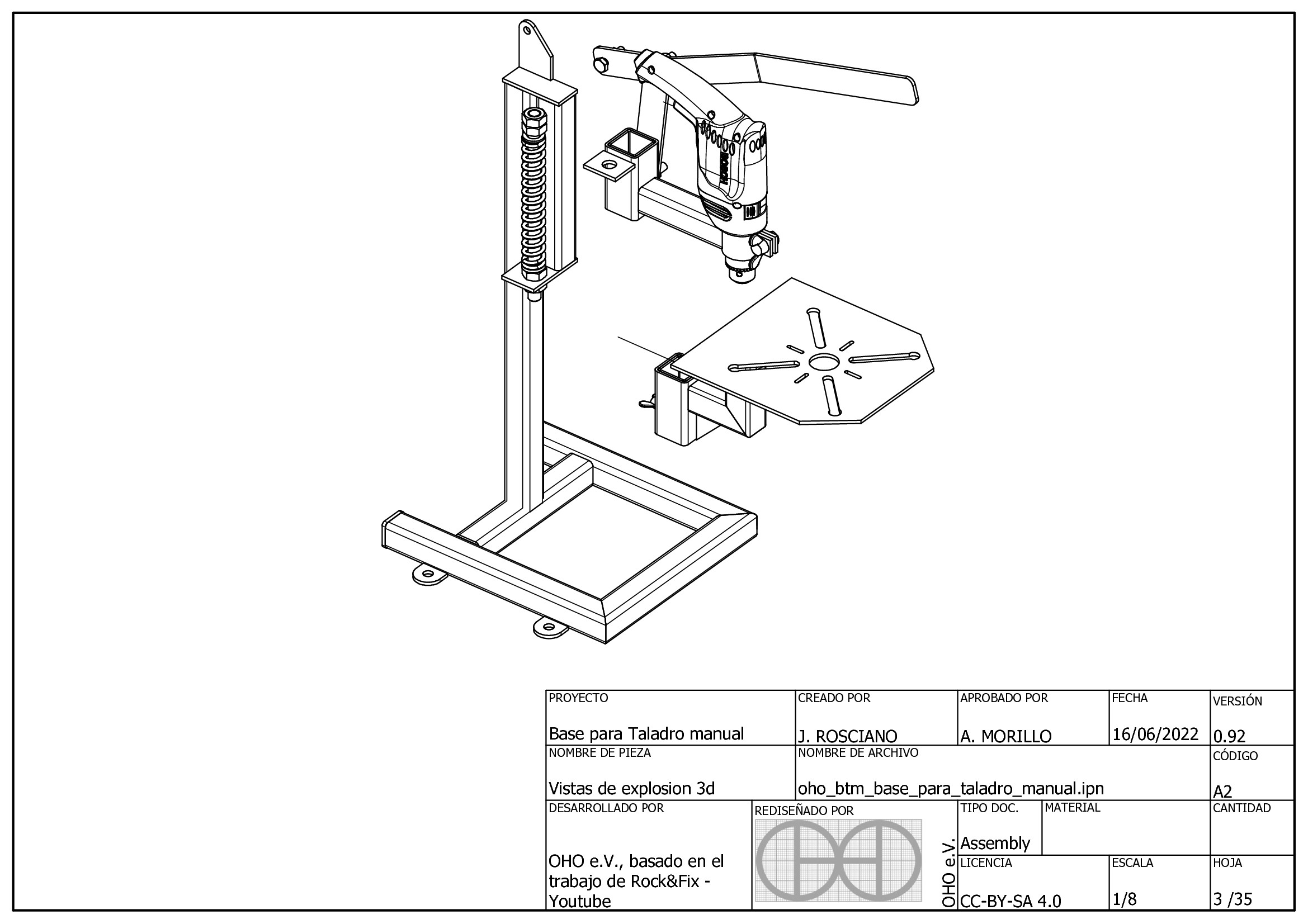

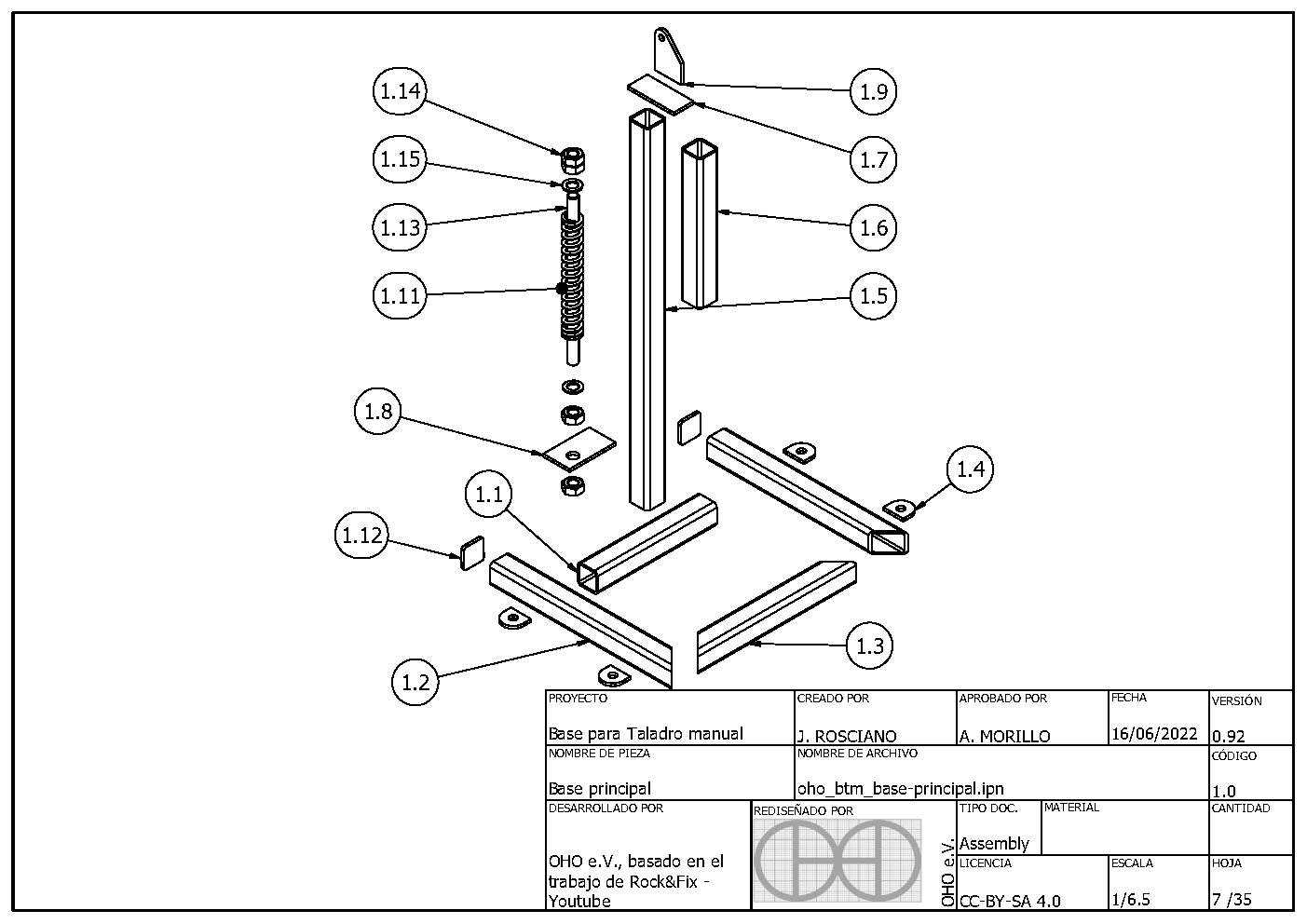

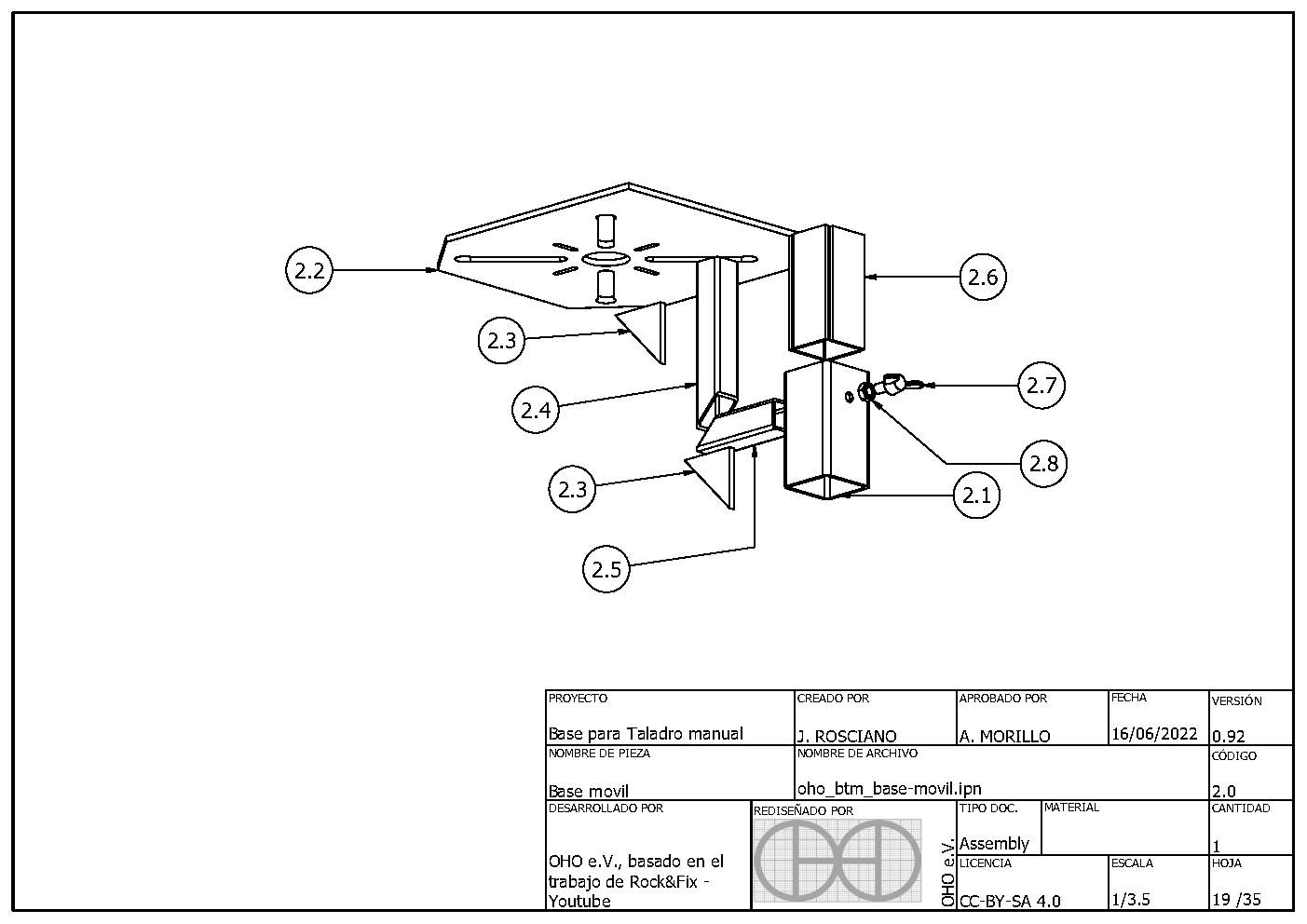

Assembly instructions

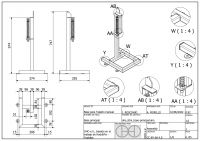

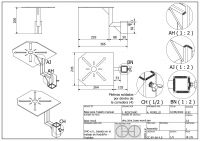

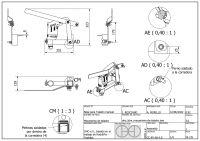

Here are some plans with the assembly sets and pieces, which can be detailed at this link

Tests, practical applications

After fabricating the drill base, the equipment was tested, which included:

- Lateral clearance: Apply moderate force on the lever, from left to right and vice versa, alternately.

- Front clearance: Apply moderate force on the lever only from top to bottom, alternately pressing the drill bit against the sample piece or other less hard piece.

- Main test: Drill holes in the test plate, using a 3/8" or 1/2" drill bit. (In the editing of the video a text or voice should be included, indicating the size of the drill bit used.)

- Measurement of the borehole:

- Measure with a vernier the diameter of the hole (to verify accuracy)

- Turn the vernier 90° horizontally and repeat this measurement (this is to verify circularity).

See the testing process in this link

+ General Reviews

Reviews

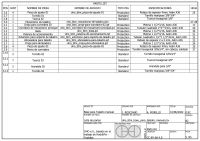

| Pos. | Qty. | Part Name | Part code | Part Type | Specifications | Review Status | Show All Comments | |

|---|---|---|---|---|---|---|---|---|

| A1 | 3D Views | |||||||

| A2 | Exploded 3D views | |||||||

| B | Parts list | |||||||

| 1.00 | Main base | |||||||

| 1.01 | 1 | Central base beam | Production | Square tubular 1 1/2*1 1/2*2mm, ASTM A36 | ||||

| 1.02 | 2 | Lateral base beam | Production | Square tubular 1 1/2*1 1/2*1 1/2*2mm, ASTM A36 | ||||

| 1.03 | 1 | Front base beam | Production | Square tubular 1 1/2*1 1/2*1 1/2*2mm, ASTM A36 | ||||

| 1.04 | 4 | Anchor ear | Production | Flat bar 1 1/2*3/16, ASTM A36 | ||||

| 1.05 | 1 | Column | Production | Square tubular 1 1/2*1 1/2*1 1/2*2mm, ASTM A36 | ||||

| 1.06 | 1 | Vertical guide | Production | Tubular square 1 1/2*1 1/2*1 1/2*2mm, ASTM A36 | ||||

| 1.07 | 1 | Guide plate 1 | Production | Flat bar 1 1/2*3/16, ASTM A36 | ||||

| 1.08 | 1 | Guide plate 02 | Production | Flat bar 1 1/2*3/16, ASTM A36 | ||||

| 1.09 | 1 | Upper ear | Production | Flat bar 1 1/2*3/16, ASTM A36 | ||||

| 1.11 | 1 | Spring | Buy | Spring L 196mm, D 25mm, d 2.5mm, n 17 turns, F 22kg | ||||

| 1.12 | 2 | Tube cap | Production | Plate 1 1/2*3/16, ASTM A36 | ||||

| 1.13 | 1 | Threaded rod | Standard | Threaded rod, 5/8" x 280mm | ||||

| 1.14 | 4 | Nut 01 | Standard | Nut, 5/8 | ||||

| 1.15 | 2 | Washer 01 | Standard | Washer, for 5/8 | ||||

| 2.00 | 1 | Mobile base | ||||||

| 2.01 | 1 | Sliding mobile base | Production | Square tubular 2*2"*2mm, ASTM A36 | ||||

| 2.02 | 1 | Movable base plate | Production | Plate, 5mm, ASTM A36 | ||||

| 2.03 | 2 | Gusset | Production | Plate 1 1/2*3/16, ASTM A36 | ||||

| 2.04 | 1 | Mobile base extension | Production | Square tubular 1 1/2*1 1/2*1 1/2*2mm, ASTM A36 | ||||

| 2.05 | 1 | Mobile base extension 02 | Production | Square tubular 1 1/2*1 1/2*1 1/2*2mm, ASTM A36 | ||||

| 2.06 | 4 | Adjusting piece 01 | Production | 4mm thick piece of scrap, ASTM A36 | ||||

| 2.07 | 1 | Screw 01 | Standard | Wing nut 3/8*3/4" | ||||

| 2.08 | 1 | Nut 02 | Standard | Hexagonal nut 3/8" | ||||

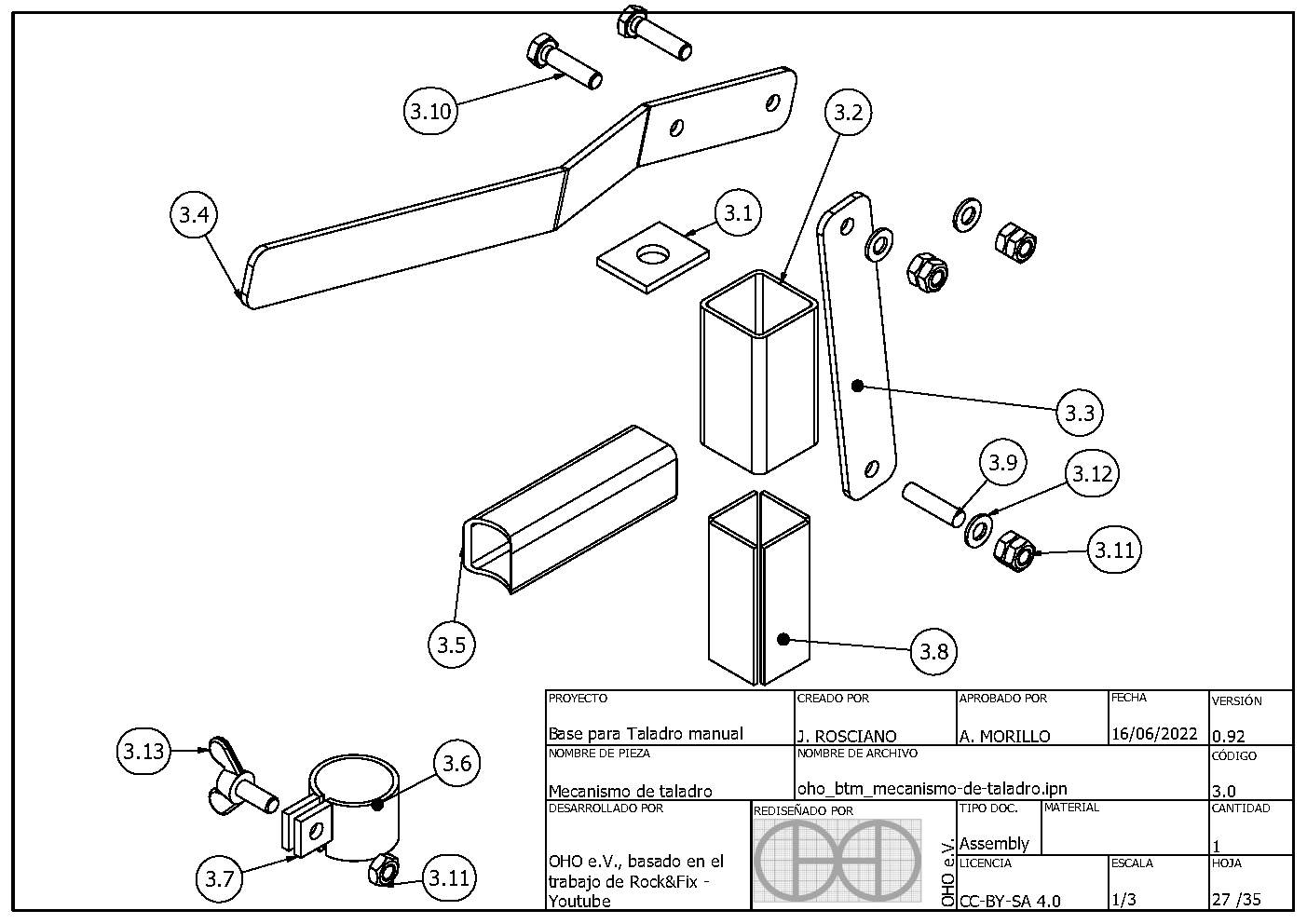

| 3.00 | 1 | Drilling mechanism | ||||||

| 3.01 | 1 | Ear for slide 02 | Production | Plate 1 1/2*3/16, ASTM A36 | ||||

| 3.02 | 1 | Main mechanism slide | Production | Square tubular 2*2"*2mm, ASTM A36 | ||||

| 3.03 | 1 | Connecting rod | Production | Plate 1 1/2*3/16, ASTM A36 | ||||

| 3.04 | 1 | Drive lever | Production | Flat bar 1 1/2*3/16, ASTM A36 | ||||

| 3.05 | 1 | Extension for drill support | Production | Square tubular 1 1/2*1 1/2*1 1/2*2mm, ASTM A36 | ||||

| 3.06 | 1 | Clamp for drill | Production | 2 to 3mm thick strip, ASTM A36 | ||||

| 3.07 | 1 | Ear for clamp | Production | Flat bar 1 1/2*3/16, ASTM A36 | ||||

| 3.08 | 4 | Adjusting piece 02 | Production | 4mm thick strip, ASTM A36 | ||||

| 3.09 | 1 | Slide bolt | Production | Hexagonal bolt 3/8x3/4", headless, welded | ||||

| 3.10 | 2 | Screw 02 | Standard | Hexagonal Screw 3/8x3/4" Hex Nut 3/8x3/4 | ||||

| 3.11 | 7 | Nut 03 | Standard | Hex Nut 3/8" Hex Nut | ||||

| 3.12 | 2 | Washer 02 | Standard | Washer for 3/8" | ||||

| 3.13 | 1 | Screw 04 | Standard | 3/8*3/4" wing nut | ||||