Difference between revisions of "Solar Water Heater - Capacity 100L"

Inddigital (talk | contribs) ((by SublimeText.Mediawiker)) |

Inddigital (talk | contribs) ((by SublimeText.Mediawiker)) |

||

| Line 279: | Line 279: | ||

: A previous review stage was not carried out, but the technical observations were left for the formal certification stage, which is shown below. | : A previous review stage was not carried out, but the technical observations were left for the formal certification stage, which is shown below. | ||

<div style="margin:20px"></div> | <div style="margin:20px"></div> | ||

==== 5. Manufacturing, tests and improvements ==== | |||

----- | |||

To date, this project is on hold for manufacturing. | |||

<!-- * Workshop <br> Determination of the workshop for manufacturing: <br> Among the most important aspects to be fulfilled by the manufacturing workshop, we have: [[File:pdc_workshop3.jpg|300px|thumb]] | |||

** It does not require industrial or specialized processes such as plastic processing, CNC machining, complex chemical processes, among others | |||

** It has basic tools for working with metal and wood at a non-industrial level | |||

** It has measuring instruments appropriate to the processes, such as: vernier, tape measure, thread counter, gauges, etc. | |||

** Includes painting equipment such as compressor and spray gun | |||

** It is a space large enough and ordered for manufacturing, assembly and painting operations | |||

** It has qualified personnel in basic and intermediate works with metal, wood, painting, among others | |||

** Some parts or processes that are not available may be purchased or ordered from more specialized stores and workshops | |||

* Purchase | |||

[[File:oho_cs1_materials-list1.png|300px|thumb]] | |||

: Purchase of materials and components: | |||

: From the list of parts, the amounts of materials to be required from local suppliers were totaled | |||

** Structural profiles | |||

** Fasteners | |||

** Special profiles | |||

** Metal plates | |||

** Consumables | |||

<div style="margin:130px"></div> | |||

* Manufacturing of prototype <br> Fabrication according to specified quality standards: <br> The manufacturing process is oriented according to the order of the assemblies in the parts list and their assembly logic, this is shown in the various stages of the manufacturing video: [[File:oho_cm3_fab1.jpg|300px|thumb|link=https://www.youtube.com/watch?v=Oz5MzN0Pc_M]] | |||

** [https://www.youtube.com/watch?v=Oz5MzN0Pc_M&t=6s Introduction] | |||

** [https://www.youtube.com/watch?v=Oz5MzN0Pc_M&t=32s Cutting Blades] | |||

** [https://www.youtube.com/watch?v=Oz5MzN0Pc_M&t=82s Support table] | |||

** [https://www.youtube.com/watch?v=Oz5MzN0Pc_M&t=110s Equipment body] | |||

** [https://www.youtube.com/watch?v=Oz5MzN0Pc_M&t=284s Painting and assembly] | |||

<div style="margin:80px"></div> | |||

* Tests and improvement <br> Module tests, system tests, improvement of components: <br> Some [https://www.youtube.com/watch?v=Oz5MzN0Pc_M&t=338s tests] were carried out on the equipment, to verify the correct adjustment of the parts and the efficiency in its operation. [[File:oho_cm3_wtest1.jpg|300px|thumb|link=https://www.youtube.com/watch?v=Oz5MzN0Pc_M&t=338s]] | |||

** Lateral slack: Apply moderate force on the lever, from left to right and vice versa, alternately. The plates do not tilt | |||

** Example of real use: Making cuts of the samples of plate and sheet | |||

** Visual detail of the cut: Straight shape of the cut, Straight edge, no burrs | |||

<div style="margin:110px"></div> | |||

* Updates of technical documentation <br> Updates of plans, parts lists, assembly instructions: | |||

** The main plates (2.1 to 2.3) were manufactured in a thickness of 12mm, which is sufficient, instead of the 16mm initially proposed | |||

** Modification in the length of the bushings, according to the new plate thicknesses | |||

** Pieces 2.5 and 2.6, manufactured in 1/2" square bar, available in the workshop | |||

** Mobile blade (piece 2.7), with dimensions adjusted according to the leaf spring piece achieved, recovered material | |||

:Plans are expected to be updated with these changes, in order to have accurate information regarding the equipment manufactured --> | |||

==== 6. Certification DIN Spec 3105 ==== | |||

----- | |||

* Formal audit | |||

Verification of the completeness of the documents: | |||

:: * Parts list | |||

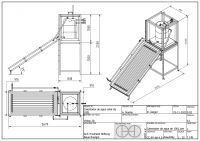

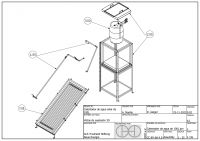

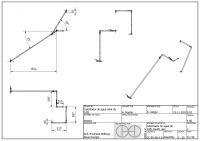

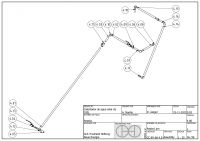

:: * Drawings of all parts and assemblies | |||

:: * Assembly instructions | |||

:: * Optional documents, technical notes | |||

: These formal aspects have been verified, the project meets them satisfactorily | |||

<div style="margin:0px"></div> | |||

* Assignment of reviewers <br> Search and assignment of peer-reviewers with sufficient expertise: | |||

**[[User:Xtech2020_review|Xtech2020_review]] | |||

** [[User:Thehunter|Thehunter]] | |||

* Peer-reviews <br> Realization of the peer reviews, technical clarification, improvements: | |||

:: * In process | |||

:: * In the [[#Parts_list|Parts list]] section, some comments have been made | |||

* Certificate <br> Issue of the certificate: In process | |||

<!-- ==== 7. Promotion, formation ==== | |||

----- | |||

* PDF documentation <br> Creation of PDF documentation, training materials etc.: | |||

* Video production <br> Production of blueprint videos, fabricaction videos etc.: | |||

* Publishing <br> Publishing on own website, Wikipedia, social media: | |||

* Use in projects <br> Use in development cooperation projects, cooperation with partners: | |||

--> | |||

</div> | </div> | ||

Revision as of 01:36, 21 January 2023

|

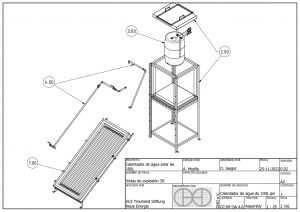

Solar Water Heater - Capacity 100L Basic Data Category: Solar collectors Keywords: thermal, heater, diy, water, heating, efficiency, renewable, sustainable, winter, frost, sun, thermosiphon, collector, drainage, insulation, fiberglass License: CC BY-SA 4.0 Organization: OHO Project status: Active Certification status: In process Technical documentation Maturity of the project: prototype

Contains PDF-drawings: Yes CAD files are editable: Yes Assembly instructions are published: Yes Bill of materials is published: Yes

yes yes

|

|

Description

Manufacturing project, Supported by: GLS Treuhand Stiftung Neue Energie

Technical documentation

PDF plans | |

|

|

Files: | |

CAD files | |

|

|

Files: | |

Technical development | |

|

|

Files: | |

Project development | |

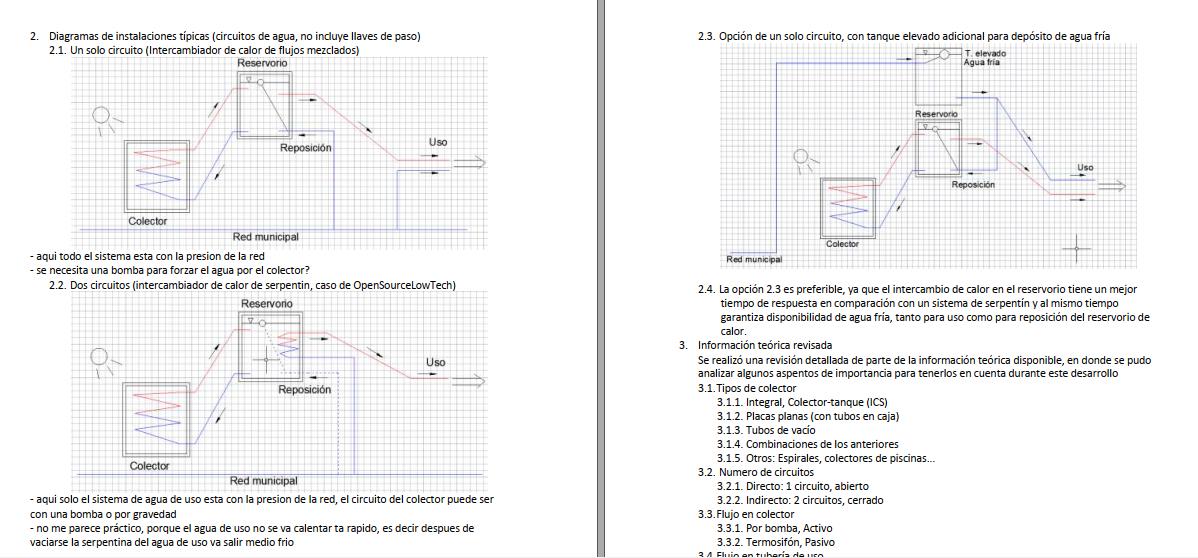

Based on the DIN 2221 standard, among others, OHO has established a series of stages in which the satisfactory completion of this project was carried out 1 Feasibility studyManufacturing as OSAT technology is possible?

2 Market analisis and requirements Functional and quantitative requirementsFunctional and quantitative requirements

3 Search & analisis DIY technologiesThe best technical solutions for all parts and components

4 Development and documentationPlans and specifications of all parts and components

5. Manufacturing, tests and improvementsTo date, this project is on hold for manufacturing. 6. Certification DIN Spec 3105

Verification of the completeness of the documents:

| |

+ General Reviews

Parts list

| Pos. | Qty. | Part Name | Part code | Part Type | Specifications | Review Status | Show All Comments | |

|---|---|---|---|---|---|---|---|---|

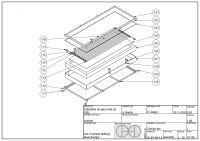

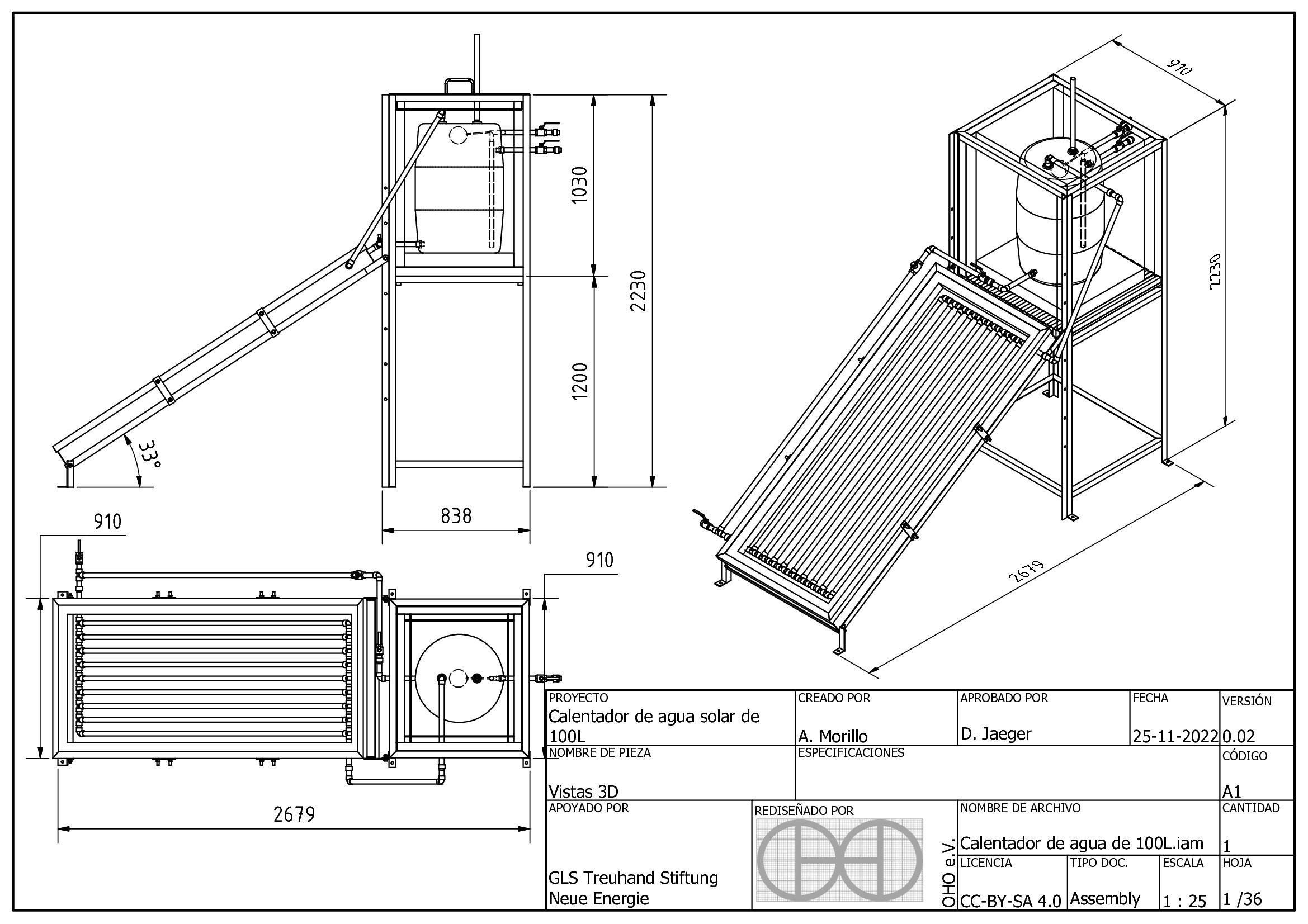

| A1 | 1 | 3D Views | ||||||

| A2 | 1 | 3D Explosion Views | ||||||

| B | Parts list | |||||||

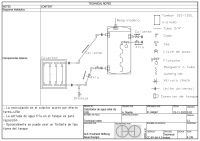

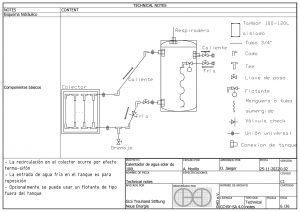

| C | Technical notes | Hydraulic Schematic, General Notes, Operation and Maintenance Manual | ||||||

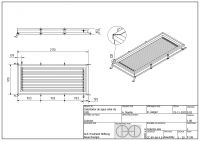

| 1.00 | 1 | Collector | ||||||

| 1.01 | 4 | Crossmember1 | Production | Angle 1 1/2*1 1/2"*4mm*910mm, A36 Steel | ||||

| 1.02 | 4 | Beam1 | Production | Angle 1 1/2*1 1/2"*4mm*2110mm, A36 Steel | ||||

| 1.03 | 1 | Transparent plate | Buy | Glass 2100*900*5mm | ||||

| 1.04 | 1 | Collector insulation | Buy | Fiberglass wool, surface 2m2, thickness 80mm | ||||

| 1.05 | 1 | Collector plate | Production | Galvanized sheet 1932*728mm, 20 gauge | ||||

| 1.06 | 4 | Cover anchor | Production | Plate 1 1/2*3/16"*175mm, A36 Steel | ||||

| 1.07 | 1 | Collector box | Production | Galvanized sheet 1200*2400mm, 20-gauge, bent and riveted | ||||

| 1.08 | 4 | Cover nut | Standard | Hex nut 1/2", UNC, grade 5 | ||||

| 1.09 | 2 | Lid plate | Production | Plate 1 1/2*3/16"*152mm, A36 Steel | ||||

| 1.10 | 4 | Cover bolt | Production | Threaded Rod 1/2"*13 UNC* 38mm | ||||

| 1.11 | 2 | Anchor ear1 | Production | Plate 1 1/2*3/16"*51mm, A36 Steel | ||||

| 1.12 | 2 | Manifold leg | Production | Angle 1 1/2*1 1/2"*4mm*150mm, A36 Steel | ||||

| 1.13 | 2 | Manifold water elbow | Standard | 3/4" PVC Elbow, threaded, high temperature | ||||

| 1.14 | 16 | Manifold water pipe 01 | Production | PVC pipe 3/4"*48mm, threaded, high temperature | ||||

| 1.15 | 16 | Manifold water tee | Standard | 3/4" PVC tee, threaded, high temperature | ||||

| 1.16 | 2 | Manifold water pipe 02 | Production | 3/4"*175mm PVC pipe, threaded, high temperature | ||||

| 1.17 | 2 | Universal union1 | Standard | 3/4" PVC universal union, threaded, high temperature | ||||

| 1.18 | 9 | Manifold water pipe 03 | Production | 3/4"*1800mm PVC pipe, threaded, high temperature | ||||

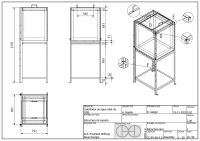

| 2.00 | 1 | Supporting structure | ||||||

| 2.01 | 4 | Column | Production | Angle 1 1/2*1 1/2"*4mm*2230mm, Steel A36 | ||||

| 2.02 | 6 | Prop1 | Production | Angle 1 1/2*1 1/2"*4mm*800mm, A36 Steel | ||||

| 2.03 | 6 | Strut2 | Production | Angle 1 1/2*1 1/2"*4mm*900mm, Steel A36 | ||||

| 2.04 | 2 | Hitch profile | Production | Angle 1 1/2*1 1/2"*4mm*2230mm, A36 Steel | ||||

| 2.05 | 4 | Anchor ear2 | Production | Plate 1 1/2*3/16"*51mm, A36 Steel | ||||

| 2.06 | 2 | Reservoir side1 | Production | Galvanized sheet 894*915mm, 20 gauge | ||||

| 2.07 | 2 | Reservoir side2 | Production | Galvanized sheet 784*975mm, 20 ga. | ||||

| 2.08 | 16 | Table1 | Production | Wooden lath 2*1"*792mm, attached to 2.09 with nails | ||||

| 2.09 | 2 | Table2 | Production | Wooden lath 2*1"*826mm | ||||

| 2.10 | 2 | Reservoir isolator1 | Buy | Fiberglass wool, surface 0.8m2, thickness 80mm | ||||

| 2.11 | 2 | Reservoir Insulator2 | Buy | Fiberglass wool, area 0.7m2, thickness 80mm | ||||

| 2.12 | 1 | Reservoir Insulator3 | Buy | Fiberglass wool, surface 0.5m2, thickness 80mm | ||||

| 2.13 | 2 | Coupling bolt | Standard | Hexagonal screw 1/2*1", UNC, grade 5 | ||||

| 2.14 | 2 | Coupling nut | Standard | Hexagonal nut 1/2", UNC, grade 5 | ||||

| 2.15 | 2 | Cover plate1 | Production | Plate 1*1/8"*792mm, Steel A36 | ||||

| 2.16 | 2 | Lid plate2 | Production | Flat Plate 1*1/8"*525mm, A36 Steel | ||||

| 2.17 | 2 | Handle | Production | 1/2" round bar, L 310mm, bent | ||||

| 2.18 | 1 | Lid liner | Production | Galvanized sheet 1035*1145mm, 20 gauge, bent and riveted | ||||

| 2.19 | 1 | Reservoir insulator4 | Buy | Fiberglass wool, surface area 0.6m2, thickness 80mm | ||||

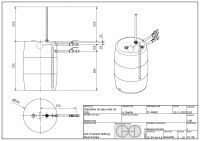

| 3.00 | 1 | Reservoir | ||||||

| 3.01 | 1 | Reservoir tank | Buy | HDPE plastic drum, Volume 100-120L | ||||

| 3.02 | 1 | Floating | Buy | Floating ball or out of tank, inlet and outlet connections 3/4" threaded | ||||

| 3.03 | 1 | Reservoir water pipe1 | Production | PVC pipe 3/4"*600mm, threaded, high temperature | ||||

| 3.04 | 2 | Reservoir tank connection | Standard | Tank connection 3/4", threaded, high temperature | ||||

| 3.05 | 1 | Breather | Production | 3/4"*500mm PVC pipe, threaded, high temperature | ||||

| 3.06 | 2 | Universal union - reservoir | Standard | 3/4" PVC universal union, threaded, high temperature | ||||

| 3.07 | 2 | Reservoir water pipe2 | Production | PVC pipe 3/4"*290mm, threaded, high temperature, sectioned for stopcock installation | ||||

| 3.08 | 2 | Reservoir stopcock, use and replacement | Standard | 1/2" stopcock | ||||

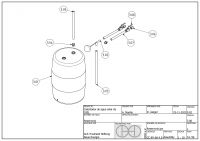

| 4.00 | 1 | Nets1 | ||||||

| 4.01 | 1 | Manifold inlet pipe1 | Production | PVC pipe 3/4"*1860mm, threaded, high temperature | ||||

| 4.02 | 1 | Manifold inlet pipe2 | Production | 3/4"*376mm PVC pipe, threaded, high temperature | ||||

| 4.03 | 1 | Pipe3 collector inlet | Production | PVC pipe 3/4"*100mm, threaded, high temperature | ||||

| 4.04 | 1 | Pipe4 manifold inlet | Production | PVC pipe 3/4"*70mm, threaded, high temperature | ||||

| 4.05 | 1 | Pipe5 manifold inlet | Production | 3/4"*50mm PVC pipe, threaded, high temperature | ||||

| 4.06 | 1 | Pipe6 collector inlet | Production | PVC pipe 3/4"*200mm, threaded, high temperature | ||||

| 4.07 | 1 | Pipe7 collector inlet | Production | PVC pipe 3/4"*84mm, threaded, high temperature | ||||

| 4.08 | 1 | Tank connection for collector inlet | Standard | Tank connection 3/4", threaded, high temperature | ||||

| 4.09 | 2 | Universal union - network | Standard | Universal union PVC 3/4", threaded, high temperature | ||||

| 4.10 | 5 | Mains elbow | Standard | PVC elbow 3/4", threaded, high temperature | ||||

| 4.11 | 1 | Check valve | Buy | 3/4" check valve, threaded, swing type | ||||

| 4.12 | 1 | Mains tee | Standard | Tee 3/4" PVC, threaded, high temperature | ||||

| 4.13 | 2 | Mains, recirculation and drain valve | Standard | 1/2" stopcock | ||||

| 4.14 | 1 | Pipe8 manifold inlet | Production | 3/4"*990mm PVC pipe, threaded, high temperature | ||||

| 4.15 | 1 | Pipe9 manifold inlet | Production | 3/4"*480mm PVC pipe, threaded, high temp. | ||||

| 4.16 | 1 | Pipe10 manifold inlet | Production | 3/4"*70mm PVC pipe, threaded, high temperature | ||||

| 4.17 | 1 | Pipe11 manifold inlet | Production | 3/4"*50mm PVC pipe, threading, high temperature | ||||

| 4.18 | 1 | Pipe12 collector inlet | Production | 3/4"*65mm PVC pipe, threaded, high temperature | ||||