Difference between revisions of "Solar Cooker - diameter 1.4m"

From OHO - search engine for sustainable open hardware projects

Inddigital (talk | contribs) ((by SublimeText.Mediawiker)) |

Inddigital (talk | contribs) ((by SublimeText.Mediawiker)) |

||

| Line 29: | Line 29: | ||

__TOC__ | __TOC__ | ||

<!-- Manufacturing project, Supported by: GLS Treuhand Stiftung Neue Energie<br> --> | <!-- Manufacturing project, Supported by: GLS Treuhand Stiftung Neue Energie<br> --> | ||

Based on: https://www.youtube.com/watch?v=joJRrljm30g | Based on: https://www.youtube.com/watch?v=joJRrljm30g-- | ||

|licence=CCBYSA40 | |licence=CCBYSA40 | ||

|typeproject=Web | |typeproject=Web | ||

| Line 58: | Line 58: | ||

|cmpfile3=oho_cs14_CAD-files.zip | |cmpfile3=oho_cs14_CAD-files.zip | ||

}} | }} | ||

{{ProjektComponent | |||

|cmptitle=Project development<!-- | |||

|cmpimage=oho_cs14_imgref1.jpg --> | |||

|cmpimg= | |||

Based on the DIN 2221 standard, among others, OHO has established a series of <i class="mw-customtoggle-div1" style="color:#1b599a;">stages</i> in which the satisfactory [[Processes_involved_in_Project_Development|completion of this project]] was carried out | |||

<div style="margin:20px"></div> | |||

<div class="mw-collapsible" id="mw-customcollapsible-div1" data-origID="mw-customcollapsible-div1"><!-- mw-collapsed --> | |||

==== 1 Feasibility study ==== | |||

----- | |||

Manufacturing as OSAT technology is possible? | |||

[[File:oho_cs14_002.jpg|300px|thumb]] | |||

* Materials, components | |||

:: Required materials and components can be sourced or replaced locally? | |||

:: ✓ Yes, | |||

:: All the materials can be found in local environments, in the case of the reflective coating it may be necessary to purchase it online, however it is not a material that is difficult to access | |||

<div style="margin:40px"></div> | |||

<!-- | |||

[[File:oho_cs14_0jLA2u_G4Dg-0708.png|300px|thumb]] | |||

* Manufacturing processes | |||

:: Required manufacturing processes can be povided locally? | |||

:: ✓ Yes | |||

:: No specialized knowledge or complex equipment is required to manufacture this turbine | |||

<div style="margin:170px"></div> | |||

[[File:Oho_teh2_W9KErFi.jpeg|300px|thumb]] | |||

:: Even in the manufacture of the generator, the tasks can be carried out by personnel with general training in workshop processes | |||

<div style="margin:200px"></div> | |||

[[File:oho_cs14_wMM2m5Lkslw.jpg|300px|thumb]] | |||

* Specific training | |||

:: Is specific training for manufacturing necessary and can be provided? | |||

:: ✗ No | |||

:: Specific training is not considered necessary for the execution of this project, however, in addition to general knowledge of workshop processes, it will be advisable to have notions in: | |||

::: * Work with fiberglass | |||

::: * Wood carving for the molds of the blades --> | |||

<!-- ::: * Static alignment --> | |||

<!-- <div style="margin:100px"></div> | |||

* Sustainability | |||

:: Do all materials and processes meet the sustainability criteria? | |||

:: ✓ Yes | |||

:: The product and its production process can be considered as [https://en.wikipedia.org/wiki/Sustainability sustainable] | |||

<div style="margin:20px"></div> | |||

==== 2 Market analisis and requirements Functional and quantitative requirements ==== | |||

---- | |||

Functional and quantitative requirements | |||

* Market analysis | |||

: Analysis of the current products on the market: | |||

[[File:oho_cs14_y7xJrGTdqxQ.png|300px|thumb]] | |||

:::[https://www.amazon.co.uk/Darrieus-Vertical-Turbine-phase-generator/dp/B075TJGVYN VAWT Darrieus Vertical Axis Wind Turbine with 3 phase axial flux generator] | |||

<div style="column-count:2"> | |||

:::: * Price [USD]: - | |||

:::: * Source: amazon | |||

:::: * Country: USA | |||

:::: * Machine condition: New | |||

:::: * Rotor diameter [m]: 1 | |||

:::: * Indicated power [W]: 100 | |||

:::: * Blade height [m]: 1 | |||

:::: * Low speed start: No | |||

</div> | |||

<div style="margin:80px"></div> | |||

[[File:oho_cs14_zIFD6oY0_fE.png|300px|thumb]] | |||

:::[https://www.amazon.es/vertical-Generador-Darrieus-controlador-autocaravana/dp/B09STD4NTZ?th=1 ADSE-ER Vertical Wind Turbine, Wind Turbine Kit 1000W Darrieus Savonius Wind Power Generator with MPPT Controller 3 Fiberglass Blades for Deck, Marine, Motorhome (12 V)] | |||

<div style="column-count:2"> | |||

:::: * Price [USD]: 1330 | |||

:::: * Source: amazon | |||

:::: * Country: China | |||

:::: * Machine condition: New | |||

:::: * Rotor diameter [m]: 0.6 | |||

:::: * Indicated power [W]: 1000 | |||

:::: * Blade height [m]: 0.95 | |||

:::: * Low speed start: Yes | |||

</div> | |||

<div style="margin:70px"></div> | |||

[[File:oho_cs14_tRQzG5HvG9M.png|300px|thumb]] | |||

:::[https://www.alibaba.com/product-detail/promotion-vertical-wind-generator-eolienne-verticale_1600584857414.html?spm=a2700.details.0.0.23a196b5suMdCi promotion vertical wind generator eolienne verticale 1500w renewable energy] | |||

<div style="column-count:2"> | |||

:::: * Price [USD]: 432 | |||

:::: * Source: alibaba | |||

:::: * Country: China | |||

:::: * Machine condition: New | |||

:::: * Rotor diameter [m]: 0.6 | |||

:::: * Indicated power [W]: 1000 | |||

:::: * Blade height [m]: 1.1 | |||

:::: * Low speed start: Yes | |||

</div> | |||

<div style="margin:160px"></div> | |||

* Requirements definition <br> Definition of the main technical data: | |||

** Rotor diameter [m]: 1 - 2 | |||

** Power [W]: 500 - 1000 | |||

** Blade height [m]: 0.8 - 1.5 | |||

<div style="margin:20px"></div> | |||

* Optimal functions and features <br> Definition of necessary/optional functions and features: | |||

** Generator: Mandatory | |||

** Low speed start: Mandatory | |||

** Battery and charge controller: Desirable | |||

<div style="margin:20px"></div> | |||

==== 3 Search & analisis DIY technologies ==== | |||

---- | |||

The best technical solutions for all parts and components | |||

* OHO Search engine | |||

: Customization of the OHO search engine | |||

[[File:oho_cs14_oho-search1.jpg|300px|thumb|link=https://en.oho.wiki/wiki/Special:RunQuery/projectSearch?pfRunQueryFormName=projectSearch&ProjektSearch%5Bsearch%5D=turbine+vertical&wpRunQuery=Search]] | |||

: When doing a search in our repository, Darrieus-type turbines are loaded together with the group of vertical axis turbines, generating some results like those shown, even from equipment that is not strictly Darrieus, but with similar operating principles. | |||

<div style="margin:120px"></div> | |||

* Manual search | |||

: Manual search in Google, Youtube, special websites etc. | |||

[[File:oho_cs14_nT7QgD_PSlc.jpg|300px|thumb|link=https://www.youtube.com/watch?v=nT7QgD_PSlc]] | |||

<div style="column-count:2"> | |||

:::: * Title: Building a vertical axis wind turbine_H type | |||

:::: * Views: 2469 | |||

:::: * Likes: 57 | |||

:::: * Comments: 8 | |||

:::: * Blade height [m]: 1.2 | |||

:::: * Low speed start: Pitch control | |||

:::: * Generator: 12V DC motor with reducer | |||

:::: * Airfoil: NACA 0018 | |||

</div> | |||

<div style="margin:140px"></div> | |||

[[File:oho_cs14_7GipP7c.jpeg|300px|thumb|link=https://www.youtube.com/shorts/Alf6EOTmlHM]] | |||

<div style="column-count:2"> | |||

:::: * Title: DIY 1kw Darrieus VAWT | |||

:::: * Views: 51292 | |||

:::: * Likes: 794 | |||

:::: * Comments: 37 | |||

:::: * Power [W]: 608 | |||

:::: * Low speed start: No | |||

:::: * Blade height [m]: 2 | |||

:::: * [https://www.fieldlines.com/index.php/topic,150186.0.html Main reference machine] | |||

</div> | |||

<div style="margin:300px"></div> | |||

[[File:oho_cs14_DTETK1Clb7w.jpg|300px|thumb|link=https://www.youtube.com/watch?v=DTETK1Clb7w]] | |||

<div style="column-count:2"> | |||

:::: * Title: DIY VAWT wind turbine generator 2016 | |||

:::: * Views: 71797 | |||

:::: * Likes: 482 | |||

:::: * Comments: 20 | |||

:::: * Blade height [m]: 1.2 | |||

:::: * Power [W]: 70 | |||

:::: * Low speed start: No | |||

:::: * Generator: Axial flux alternator | |||

:::: * Theoretical efficiency [%]: 29 | |||

</div> | |||

<div style="margin:140px"></div> | |||

[[File:oho_cs14_0jLA2u_G4Dg.jpg|300px|thumb|link=https://www.youtube.com/watch?v=0jLA2u_G4Dg]] | |||

<div style="column-count:2"> | |||

:::: * Title: Building a Vertical Axis Wind Turbine. We no longer sell this R2-40 Rotating Assembly. | |||

:::: * Views: 1712601 | |||

:::: * Likes: 12024 | |||

:::: * This example was added just to show a more robust design than usual | |||

</div> | |||

<div style="margin:200px"></div> --> | |||

<!-- * Networking | |||

: Contacting partners, associated organizations and experts | |||

[[File:oho_cs14_mFC_93DW_XQ-0017.jpg|300px|thumb|link=https://www.youtube.com/watch?v=mFC_93DW_XQ]] | |||

: During the initial stages of this project, we were able to contact the channel [https://www.youtube.com/@OpenSourceLowTech Opensourcelowtech] and exchange some ideas, for which we are very grateful | |||

: Initially, work was done on a replica of [https://www.youtube.com/watch?v=DHW392drALI one of their project], which served as experience for this case | |||

<div style="margin:160px"></div> --> | |||

<!-- ==== 4 Development and documentation ==== | |||

---- | |||

Plans and specifications of all parts and components | |||

* Analisis of functions & structures | |||

[[File:oho_cs14_011.jpg|300px|thumb|link=#Technical_development]] | |||

: Analysis of functions, assemblies and components | |||

: The conversion from wind energy to electricity occurs due to the shape of the blade profile, so one of the most important aspects of this project was to achieve an aerodynamic profile with the techniques and tools available for Appropriate Technologies | |||

: Additionally, the goal was set for the equipment to have a starting system at low wind speed, which was observed in commercial equipment but not much in DIY cases | |||

<div style="margin:150px"></div> | |||

* Technical solutions | |||

: Development of technical solutions for assemblies and parts | |||

: A review of the different options adopted in the DIY machines was carried out to meet each design requirement, observing the following variants for some evaluated details: | |||

:: * Evaluated detail: Blade Construction | |||

<div style="margin-left:30px"><ul> | |||

<li style="display: inline-block;"> [[File:oho_cs14_QgR5xIdiONo.jpg|thumb|none|200px|Wooden ribs covered with flexible foil|link=https://www.youtube.com/watch?v=QgR5xIdiONo]] </li> | |||

<li style="display: inline-block;"> [[File:oho_cs14_wMM2m5Lkslw.jpg|thumb|none|200px|Fiberglass covered ribs|link=https://www.youtube.com/watch?v=wMM2m5Lkslw]] </li> | |||

<li style="display: inline-block;"> [[File:oho_cs14_IFRX5s76ofM.jpg|thumb|none|200px|Wire cut foam material|link=https://www.youtube.com/watch?v=IFRX5s76ofM]] </li> | |||

<li style="display: inline-block;"> [[File:oho_cs14_lEHK4KeKxfs.jpg|thumb|none|200px|With PVC pipes|link=https://www.youtube.com/watch?v=lEHK4KeKxfs]] </li> | |||

</ul></div> | |||

:: * Evaluated detail: Airfoil | |||

<div style="margin-left:30px"><ul> | |||

<li style="display: inline-block;"> [[File:oho_cs14_IFRX5s76ofM.jpg|thumb|none|200px|NACA 0018|link=https://www.youtube.com/watch?v=IFRX5s76ofM]] </li> | |||

<li style="display: inline-block;"> [[File:oho_cs14_6SASRw4.jpeg|thumb|none|200px|NACA 1418|link=https://mdpi-res.com/d_attachment/energies/energies-13-03196/article_deploy/energies-13-03196.pdf?version=1592567343]] </li> | |||

<li style="display: inline-block;"> [[File:oho_cs14_Nd9Hyf9.jpeg|thumb|none|200px|NACA 0015|link=http://educypedia.karadimov.info/library/finalreport.pdf]] </li> | |||

<li style="display: inline-block;"> [[File:oho_cs14_jBkZZd2.jpeg|thumb|none|200px|AH93W215|link=https://www.researchgate.net/publication/335320655_A_Comparison_Study_of_Airfoils_Used_in_H-Rotor_Darrieus_Wind_Turbine]] </li> | |||

<li style="display: inline-block;"> [[File:oho_cs14_KmfOcqD.jpeg|thumb|none|200px|S-1046|link=https://www.sciencedirect.com/science/article/abs/pii/S0360544212006755]] </li> | |||

<li style="display: inline-block;"> [[File:oho_cs14_R6nQrCm.jpeg|thumb|none|200px|NACA 0024|link=https://www.semanticscholar.org/paper/Computational-Analysis-of-Various-Airfoil-Profile-Modi-Gilke/e0982a5b3c37c67a57960de9c30c162af83a0b77]] </li> | |||

</ul></div> | |||

:: * Evaluated detail: Generator type | |||

<div style="margin-left:30px"><ul> | |||

<li style="display: inline-block;"> [[File:oho_cs14_nT7QgD_PSlc.jpg|thumb|none|200px|DC Motor|link=https://www.youtube.com/watch?v=nT7QgD_PSlc]] </li> | |||

<li style="display: inline-block;"> [[File:oho_cs14_DTETK1Clb7w.jpg|thumb|none|200px|Axial flux alternator|link=https://www.youtube.com/watch?v=DTETK1Clb7w]] </li> | |||

<li style="display: inline-block;"> [[File:oho_cs14_0BE5cuap2AQ.jpg|thumb|none|200px|Car alternator|link=https://www.youtube.com/watch?v=0BE5cuap2AQ]] </li> | |||

</ul></div> | |||

:: * Evaluated detail: Self start method | |||

<div style="margin-left:30px"><ul> | |||

<li style="display: inline-block;"> [[File:oho_cs14_wHu1bRso4u0.jpg|thumb|none|200px|Combined Savonius|link=https://www.youtube.com/watch?v=wHu1bRso4u0]] </li> | |||

<li style="display: inline-block;"> [[File:oho_cs14_paj1myckU-w.jpg|thumb|none|200px|Variable pitch|link=https://www.youtube.com/watch?v=paj1myckU-w]] </li> | |||

<li style="display: inline-block;"> [[File:oho_cs14_BlIM43fRp60.jpg|thumb|none|200px|Magnus effect|link=https://www.youtube.com/watch?v=BlIM43fRp60]] </li> | |||

</ul></div> | |||

:: * Evaluated detail: Mast Type | |||

<div style="margin-left:30px"><ul> | |||

<li style="display: inline-block;"> [[File:oho_cs14_7GipP7c.jpeg|thumb|none|200px|Truss tower|link=https://www.youtube.com/shorts/Alf6EOTmlHM]] </li> | |||

<li style="display: inline-block;"> [[File:oho_cs14_0B1Fb2m0W20.jpg|thumb|none|200px|Tubular post|link=https://www.youtube.com/watch?v=0B1Fb2m0W20]] </li> | |||

</ul></div> | |||

: See related comments: [[{{TALKPAGENAME}}|Discussion]] | |||

<div style="margin:20px"></div> | |||

* Technical documentation | |||

: Creation of plans, parts lists, assembly instructions | |||

: Once all the necessary information was available, the [[#PDF_plans|project plans]] were prepared | |||

<div style="margin:0px"></div> | |||

* Peer-Reviews | |||

: Peer-Reviews by the community, team members, experts etc. | |||

: Among some revised and improved aspects of the project, prior to the publication of the plans, we can mention: | |||

:: * Improvements in the presentation format of technical notes, they include illustrations on manufacturing | |||

:: * Using a template with a grid for quick copying of the airfoil and manufacturing of the blades | |||

:: * Use of metal straps to hold the Savonius internal blade (version 0.02 - part 1.18) | |||

:: * Simplification in the H-shape of the turbine structure, without requiring tensioning trusses in it | |||

<div style="margin:20px"></div> | |||

==== 5. Manufacturing, tests and improvements ==== | |||

----- | |||

To date, this project is on hold for manufacturing | |||

* Workshop <br> Determination of the workshop for manufacturing: | |||

: This project is considered as belonging to the group of Appropriate Technologies, for which it has been developed with the intention of the greatest possible access to processes and materials by the developers, with a basic, moderately equipped workshop, however, it is necessary also have the following facilities: | |||

:: * Tools and materials for working with fiberglass | |||

:: * Tools for carving wood, in the case of blade moulds | |||

:: * Adequate spaces, tools and equipment to carry out electrical work, in the case of generator connections and the associated electrical network | |||

: Although these conditions do not pose a greater difficulty during manufacturing, it is left to the developer's discretion to choose between carrying out this work or requesting the services of a third party to guarantee a professional work | |||

The purchasing, prototype manufacturing, testing, and documentation updating sub-processes, will be developed once the manufacturing stage is completed --> | |||

<!-- * Purchase | |||

[[File:oho_cs14_materials-list1.png|300px|thumb]] | |||

: Purchase of materials and components: | |||

: From the list of parts, the amounts of materials to be required from local suppliers were totaled | |||

** Structural profiles | |||

** Fasteners | |||

** Special profiles | |||

** Metal plates | |||

** Consumables | |||

<div style="margin:130px"></div> | |||

* Manufacturing of prototype <br> Fabrication according to specified quality standards: <br> The manufacturing process is oriented according to the order of the assemblies in the parts list and their assembly logic, this is shown in the various stages of the manufacturing video: [[File:oho_cm3_fab1.jpg|300px|thumb|link=https://www.youtube.com/watch?v=Oz5MzN0Pc_M]] | |||

** [https://www.youtube.com/watch?v=Oz5MzN0Pc_M&t=6s Introduction] | |||

** [https://www.youtube.com/watch?v=Oz5MzN0Pc_M&t=32s Cutting Blades] | |||

** [https://www.youtube.com/watch?v=Oz5MzN0Pc_M&t=82s Support table] | |||

** [https://www.youtube.com/watch?v=Oz5MzN0Pc_M&t=110s Equipment body] | |||

** [https://www.youtube.com/watch?v=Oz5MzN0Pc_M&t=284s Painting and assembly] | |||

<div style="margin:80px"></div> | |||

* Tests and improvement <br> Module tests, system tests, improvement of components: <br> Some [https://www.youtube.com/watch?v=Oz5MzN0Pc_M&t=338s tests] were carried out on the equipment, to verify the correct adjustment of the parts and the efficiency in its operation. [[File:oho_cm3_wtest1.jpg|300px|thumb|link=https://www.youtube.com/watch?v=Oz5MzN0Pc_M&t=338s]] | |||

** Lateral slack: Apply moderate force on the lever, from left to right and vice versa, alternately. The plates do not tilt | |||

** Example of real use: Making cuts of the samples of plate and sheet | |||

** Visual detail of the cut: Straight shape of the cut, Straight edge, no burrs | |||

<div style="margin:110px"></div> | |||

* Updates of technical documentation <br> Updates of plans, parts lists, assembly instructions: | |||

** The main plates (2.1 to 2.3) were manufactured in a thickness of 12mm, which is sufficient, instead of the 16mm initially proposed | |||

** Modification in the length of the bushings, according to the new plate thicknesses | |||

** Pieces 2.5 and 2.6, manufactured in 1/2" square bar, available in the workshop | |||

** Mobile blade (piece 2.7), with dimensions adjusted according to the leaf spring piece achieved, recovered material | |||

:Plans are expected to be updated with these changes, in order to have accurate information regarding the equipment manufactured --> | |||

<!-- ==== 6. Certification DIN Spec 3105 ==== | |||

----- | |||

* Formal audit | |||

[[File:pdc_certification-process-diag-page1.jpg|300px|thumb|link=Process_-_Certification_DIN_Spec_3105]] | |||

: Verification of the completeness of the documents: | |||

:: * Parts list | |||

:: * Drawings of all parts and assemblies | |||

:: * Assembly instructions | |||

:: * Optional documents, technical notes | |||

:: * These formal aspects have been verified, the project meets them satisfactorily | |||

<div style="margin:0px"></div> | |||

* Assignment of reviewers <br> Search and assignment of peer-reviewers with sufficient expertise: | |||

**[[User:Xtech2020_review|Xtech2020_review]] | |||

** [[User:Thehunter|Thehunter]] | |||

* Peer-reviews <br> Realization of the peer reviews, technical clarification, improvements: | |||

:: * In process | |||

:: * In the [[#Parts_list|Parts list]] section, some comments have been made | |||

* Certificate <br> Issue of the certificate: In process --> | |||

<!-- | |||

<!~~ ==== 7. Promotion, formation ==== | |||

----- | |||

* PDF documentation <br> Creation of PDF documentation, training materials etc.: | |||

* Video production <br> Production of blueprint videos, fabricaction videos etc.: | |||

* Publishing <br> Publishing on own website, Wikipedia, social media: | |||

* Use in projects <br> Use in development cooperation projects, cooperation with partners: | |||

~~> | |||

</div> --> | |||

}} | |||

|Materials= | |Materials= | ||

{{ProjektMaterials | {{ProjektMaterials | ||

Revision as of 22:16, 24 January 2023

|

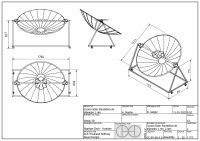

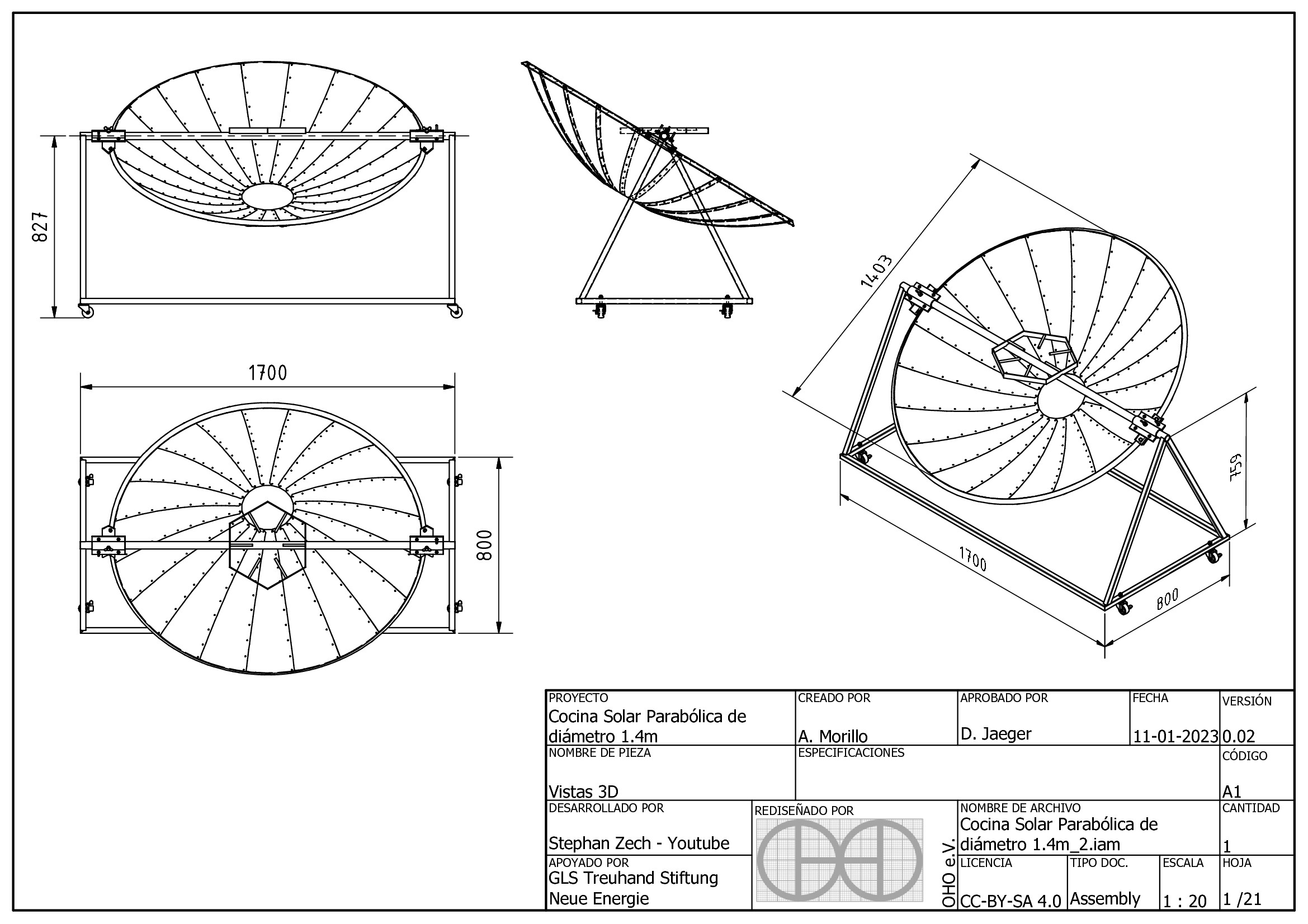

Solar Cooker - diameter 1.4m Basic Data Category: Solar cooker Keywords: solar, oven, parabolic, energy, reflector, cook, food, watt, boil, mirror License: CC BY-SA 4.0 Organization: OHO Project status: Active Certification status: In process Technical documentation Maturity of the project: prototype

Contains PDF-drawings: Yes CAD files are editable: Yes Assembly instructions are published: Yes Bill of materials is published: Yes

yes yes

|

|

Description

Based on: https://www.youtube.com/watch?v=joJRrljm30g--

Technical documentation

PDF plans | |

|

|

Files: | |

CAD files | |

|

|

Files: | |

Project development | |

Based on the DIN 2221 standard, among others, OHO has established a series of stages in which the satisfactory completion of this project was carried out

1 Feasibility studyManufacturing as OSAT technology is possible?

| |

+ General Reviews

Parts list

| Pos. | Qty. | Part Name | Part code | Part Type | Specifications | Review Status | Show All Comments | |

|---|---|---|---|---|---|---|---|---|

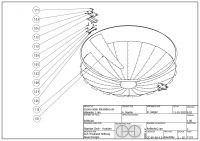

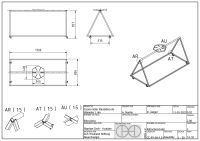

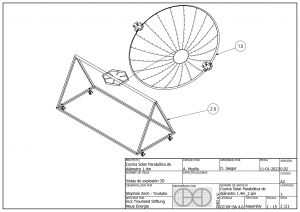

| A1 | 1 | 3D Views | ||||||

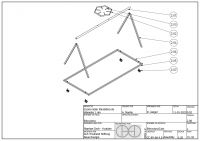

| A2 | 1 | 3D Explosion Views | ||||||

| B | Parts list | |||||||

| C | Technical notes | |||||||

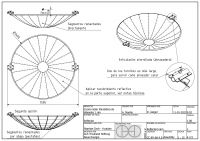

| 1.00 | 1 | Reflector | ||||||

| 1.01 | 20 | Parbolic segment | 26 gauge galvanized steel sheet (0.48 mm) | |||||

| 1.02 | 2 | Articulation support | Angle 1 1/2*1 1/2*1 1/2*4mm*150mm | |||||

| 1.03 | 4 | Clamp channel | Round iron pipe 1 1/4", sch40*150mm | |||||

| 1.04 | 8 | Clamp ear | Plate 1*1/8"*150mm | |||||

| 1.05 | 4 | Articulation screw | Hexagonal bolt M8*16mm, grade 5 | |||||

| 1.06 | 4 | Hinge nut | Hexagonal nut M8, grade 5 | |||||

| 1.07 | 4 | Hinge washer | Flat washer for M8 | |||||

| 1.08 | 6 | Clamp screw1 | Hexagonal screw M6*12mm, grade 5 | |||||

| 1.09 | 2 | Clamp screw2 | Hexagonal bolt M6*40mm, grade 5 | |||||

| 1.10 | 8 | Clamp nut | Hexagonal nut M6, grade 5 | |||||

| 1.11 | 2 | Clamp bolt | Wing bolt M8*12mm | |||||

| 1.12 | 2 | Clamp nut | Hexagonal nut M8, welded | |||||

| 1.13 | 1 | Reflector band | Plate 1*1/8"*4473mm | |||||

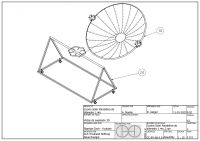

| 2.00 | 1 | Structure | ||||||

| 2.01 | 2 | Fixed shaft | Round iron pipe, 1", sch40 | |||||

| 2.02 | 6 | Burner beams | Plate 1*1/8"*200mm | |||||

| 2.03 | 6 | Burner support | Round iron bar 10mm*100mm | |||||

| 2.04 | 4 | Strut | 1*1"*2mm*830mm square iron pipe 1*1"*2mm*830mm | |||||

| 2.05 | 2 | Base1 | Square iron pipe 1*1"*2mm*1700mm | |||||

| 2.06 | 2 | Base2 | Square iron pipe 1*1"*2mm*800mm | |||||

| 2.07 | 4 | Adjustable wheel | Caster type adjustable wheel or similar, diameter 2". | |||||