Difference between revisions of "Plastic injection machine, Precious Plastic"

Inddigital (talk | contribs) ((by SublimeText.Mediawiker)) |

|||

| (8 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

{{ | {{Projekt2 | ||

|Images={{ProjektImages | |Images= | ||

{{ProjektImages | |||

|projectimage=injection.jpg | |||

}} | |||

{{ProjektImages | |||

|projectimage=Plastic injection machine.png | |projectimage=Plastic injection machine.png | ||

}}{{ProjektImages | }} | ||

{{ProjektImages | |||

|projectimage=preciousplastic injection machine.png | |projectimage=preciousplastic injection machine.png | ||

}}{{ProjektImages | }} | ||

{{ProjektImages | |||

|projectimage=Precious Plastic - Build the injection (part 3.3) 0-12 screenshot.png | |||

}} | |||

{{ProjektImages | |||

|projectimage=Injection-image.jpg | |projectimage=Injection-image.jpg | ||

}} | }} | ||

| Line 24: | Line 33: | ||

|bill_materials_pub=yes | |bill_materials_pub=yes | ||

|contains_pdf_drawings=yes | |contains_pdf_drawings=yes | ||

|technology_readyness_level= | |technology_readyness_level=6 | ||

|TechDoc={{ | |Desc= | ||

{{ProjektComponent2 | |||

|cmpimage=community-injection2.jpg | |||

|cmptitle=Description | |||

|cmpimg= | |||

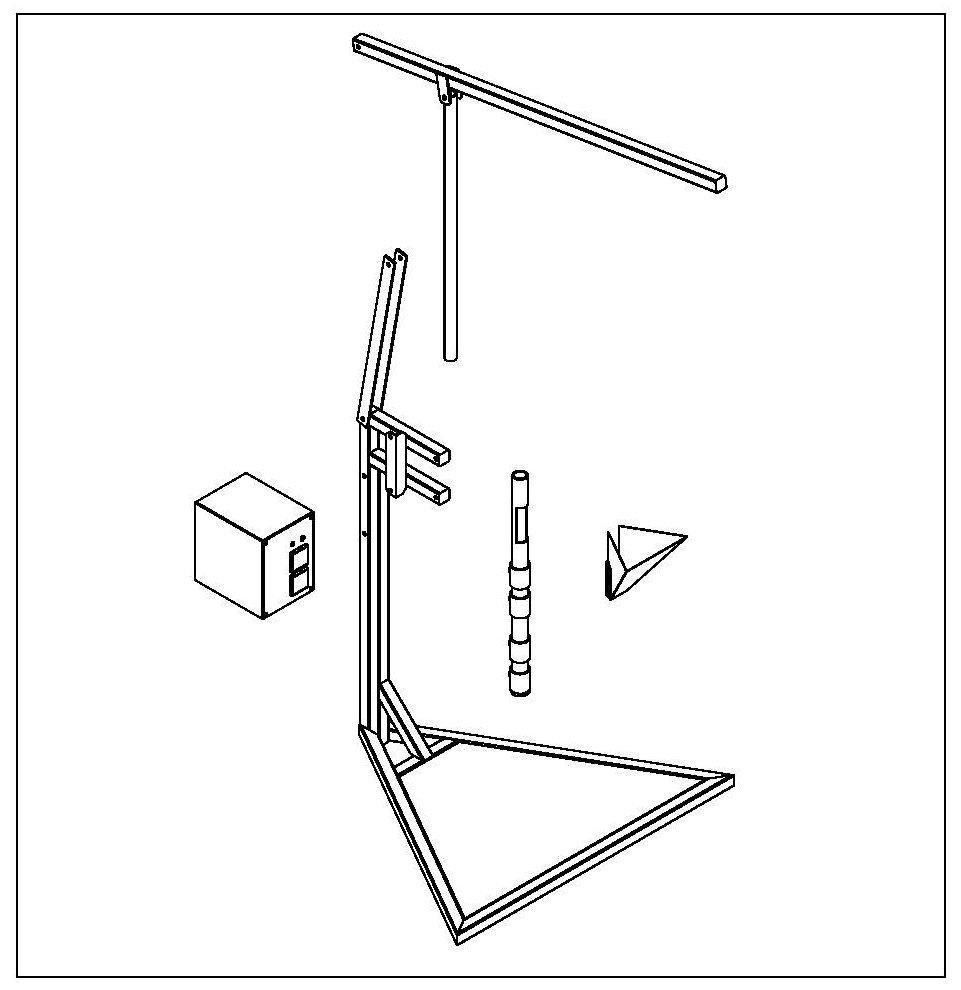

In order to develop a homemade machine, capable of making parts by injection of recycled plastic, this project is presented, developed by the Precious Plastic organization (P.P.), where a device is manufactured from reused iron parts and some electrical components, efficient for this purpose. Details of the original development are on the [https://community.preciousplastic.com/academy/build/injection P.P. website]. | |||

}} | |||

<div style="margin:20px"></div> | |||

{{ProjektComponent2 | |||

|cmptitle= Technical data | |||

|cmpimg= | |||

Some features of the machine: | |||

* Type: Injection | |||

* Version: 1.0 | |||

* Weight: 23 kg | |||

* Dimensions: 830 x 700 x 1300 mm | |||

* Barrel volume: 150 cm³ | |||

* Leverage: 3 | |||

* Injection pressure: 45 bars | |||

* Max mould size: 360 x 330 mm | |||

* Injections p/h: 10 - 30 | |||

* Voltage: 220V | |||

* AMP: 2.6A | |||

* Input Flake Size: Medium, Small | |||

* Temperature control: PID Controller, Solid State Relay and Thermocouple | |||

* Processed material: HDPE, LDPE, PP, PS | |||

* Output: 10-30 injections per hour depending on mould | |||

}} | |||

|TechDoc= | |||

{{ProjektComponent2 | |||

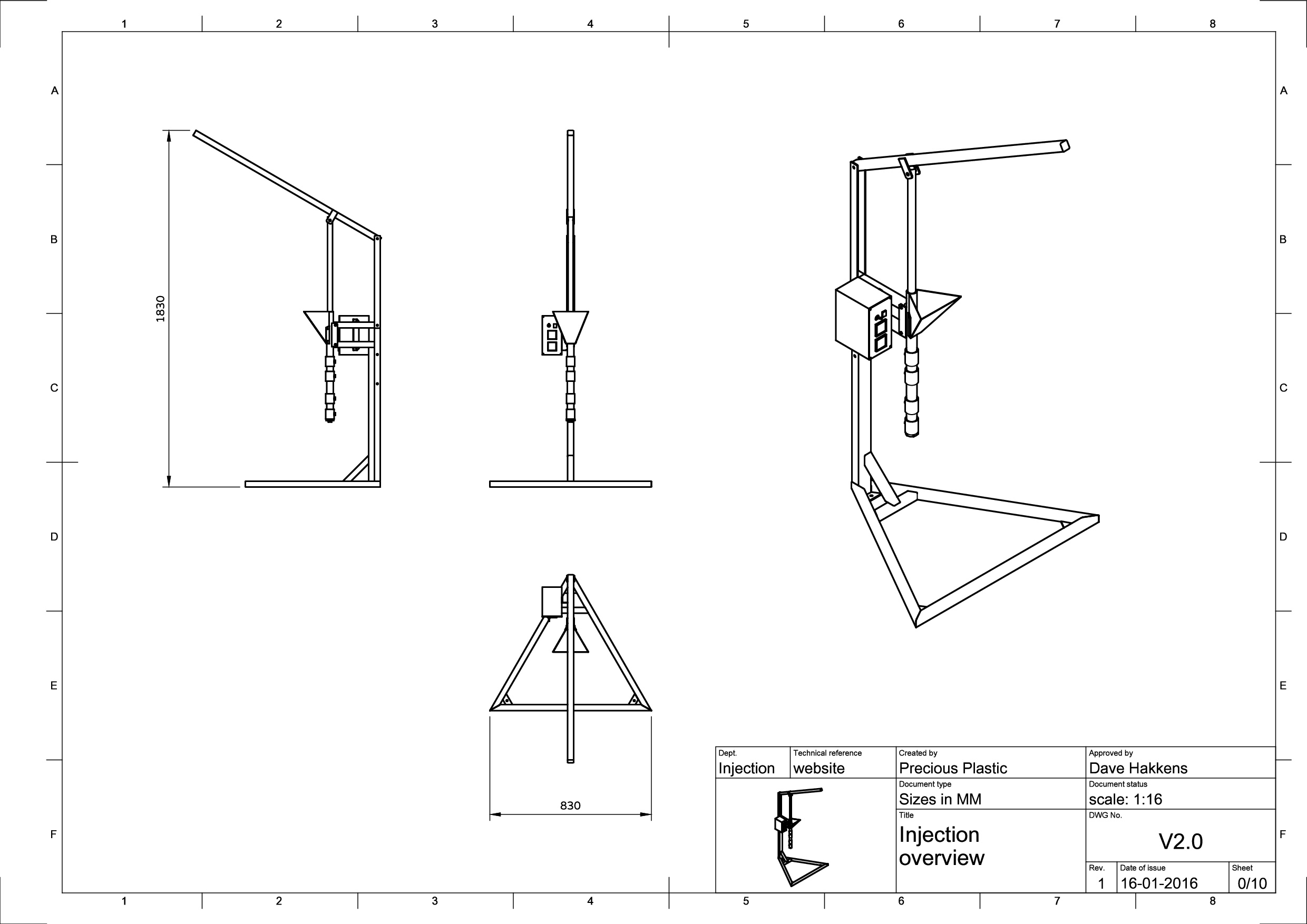

|cmptitle=Plastic injection machine - all drawings | |cmptitle=Plastic injection machine - all drawings | ||

|cmpimage=PP_pim_001.jpg | |||

|cmpfile1=Injection all.pdf | |cmpfile1=Injection all.pdf | ||

}} | }} | ||

{{ProjektComponent2 | |||

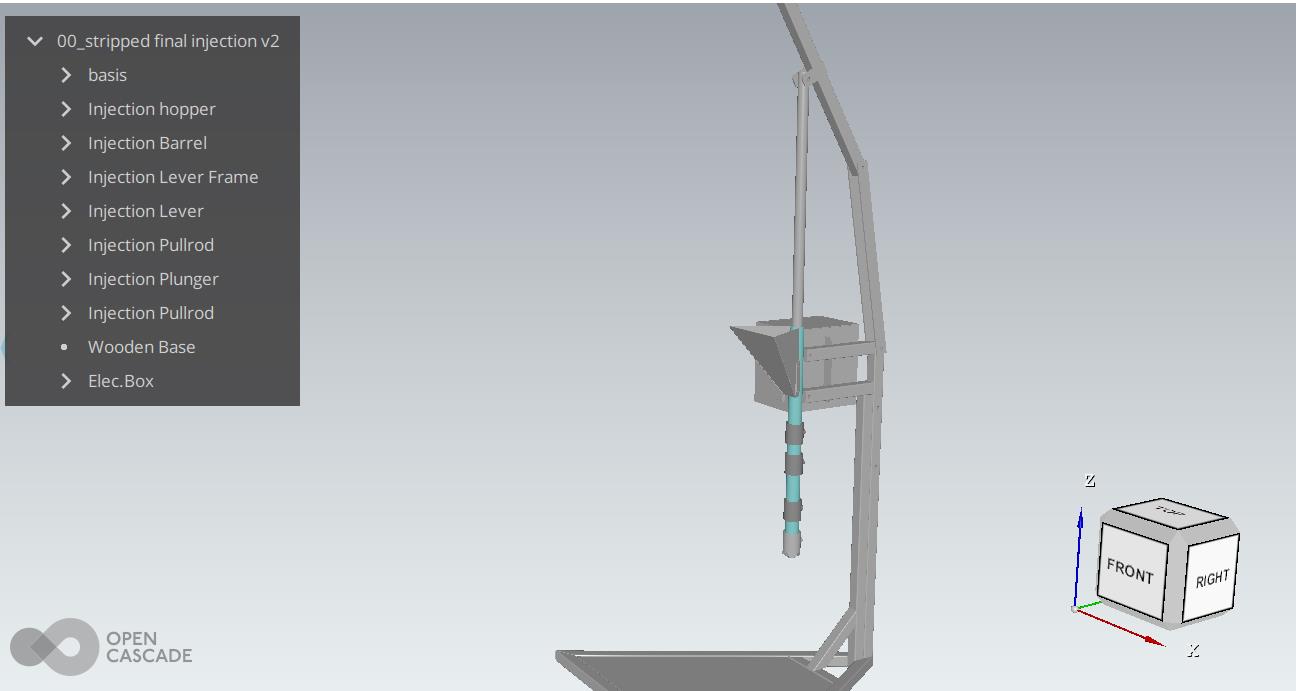

|cmptitle=Plastic injection machine - CAD-files | |cmptitle=Plastic injection machine - CAD-files | ||

|cmpimage=CAD1.jpg | |||

|cmpfile1=Injection V2.0 CAD.iges | |cmpfile1=Injection V2.0 CAD.iges | ||

|cmpfile2=Injection V2.0 CAD.sat | |cmpfile2=Injection V2.0 CAD.sat | ||

| Line 38: | Line 76: | ||

|cmpfile4=Injection V2.0 CAD.f3d | |cmpfile4=Injection V2.0 CAD.f3d | ||

}} | }} | ||

|Materials={{ProjektMaterials | {{ProjektComponent2 | ||

|cmptitle=Plastic injection machine - bill of materials | |||

|cmpfile1=Bill-of-Materials-Injection.pdf | |||

}} | |||

<div style="margin:20px"></div> | |||

{{ProjektComponent2 | |||

|cmptitle=Other technical notes | |||

|cmpimage=Precious Plastic - Build the injection (part 3.3) 3-39 screenshot.png | |||

|cmpimg= | |||

<h3>Tips & tricks while making</h3> | |||

* Take care welding around the hopper tabs. The heat can easily distort the barrel, ruining that perfect slide. | |||

* Adding an insulated barrel cover will increase efficiency and reduce the chances of the user accidentally touching the barrel when hot. | |||

* When building, the lever is stronger as a circular profile when compared to a square profile. Which will reduce the likelihood of bending it. | |||

}} | |||

<div style="margin:20px"></div> | |||

{{ProjektComponent2 | |||

|cmptitle=Assembly instructions | |||

<!-- |cmpimage= --> | |||

|cmpimg= | |||

Here are some plans with the assembly sets and pieces, which can be detailed at [https://www.youtube.com/watch?v=ogI8kt0w43Y this link] | |||

<div class="mw-collapsible" id="mw-customcollapsible-div1" data-origID="mw-customcollapsible-div1"> | |||

<div style="text-align:left;"> | |||

<i class="mw-customtoggle-div1" style="color:#1b599a;">Zoom in</i> | |||

</div> | |||

<div class="res-img col-auto col-sm-auto col-md-auto col-lg-5 col-xl-5"> | |||

[[File:assembly1.jpg]] | |||

<div style="margin:20px"></div> | |||

[[File:PP_pim_002.jpg]] | |||

<div style="margin:20px"></div> | |||

[[File:PP_pim_004.jpg]] | |||

<div style="margin:20px"></div> | |||

[[File:PP_pim_005.jpg]] | |||

<div style="margin:20px"></div> | |||

[[File:PP_pim_010.jpg]] | |||

</div> | |||

</div> | |||

<div class="mw-collapsible mw-collapsed" id="mw-customcollapsible-div1" data-origID="mw-customcollapsible-div1"> | |||

<div style="text-align:left;;"> | |||

<i class="mw-customtoggle-div1" style="color:#1b599a;">Zoom out</i> | |||

</div> | |||

<div class="res-img" style="width: 800px"> | |||

[[File:assembly1.jpg]] | |||

<div style="margin:20px"></div> | |||

[[File:PP_pim_002.jpg]] | |||

<div style="margin:20px"></div> | |||

[[File:PP_pim_004.jpg]] | |||

<div style="margin:20px"></div> | |||

[[File:PP_pim_005.jpg]] | |||

<div style="margin:20px"></div> | |||

[[File:PP_pim_010.jpg]] | |||

</div> | |||

</div> | |||

}} | |||

<div style="margin:20px"></div> | |||

{{ProjektComponent2 | |||

|cmptitle=Tests, practical applications | |||

|cmpimage=Precious Plastic - Build the injection (part 3.3) 0-17 screenshot.png | |||

|cmpimg= | |||

It can be seen that the machine can produce injected parts from recycled plastic, see [https://www.youtube.com/watch?v=qtZv96ciFIU?t=641 this point in the video]. | |||

}} | |||

|Materials= | |||

{{ProjektMaterials | |||

|matpartnumber=1 | |matpartnumber=1 | ||

|matquantity=1 | |matquantity=1 | ||

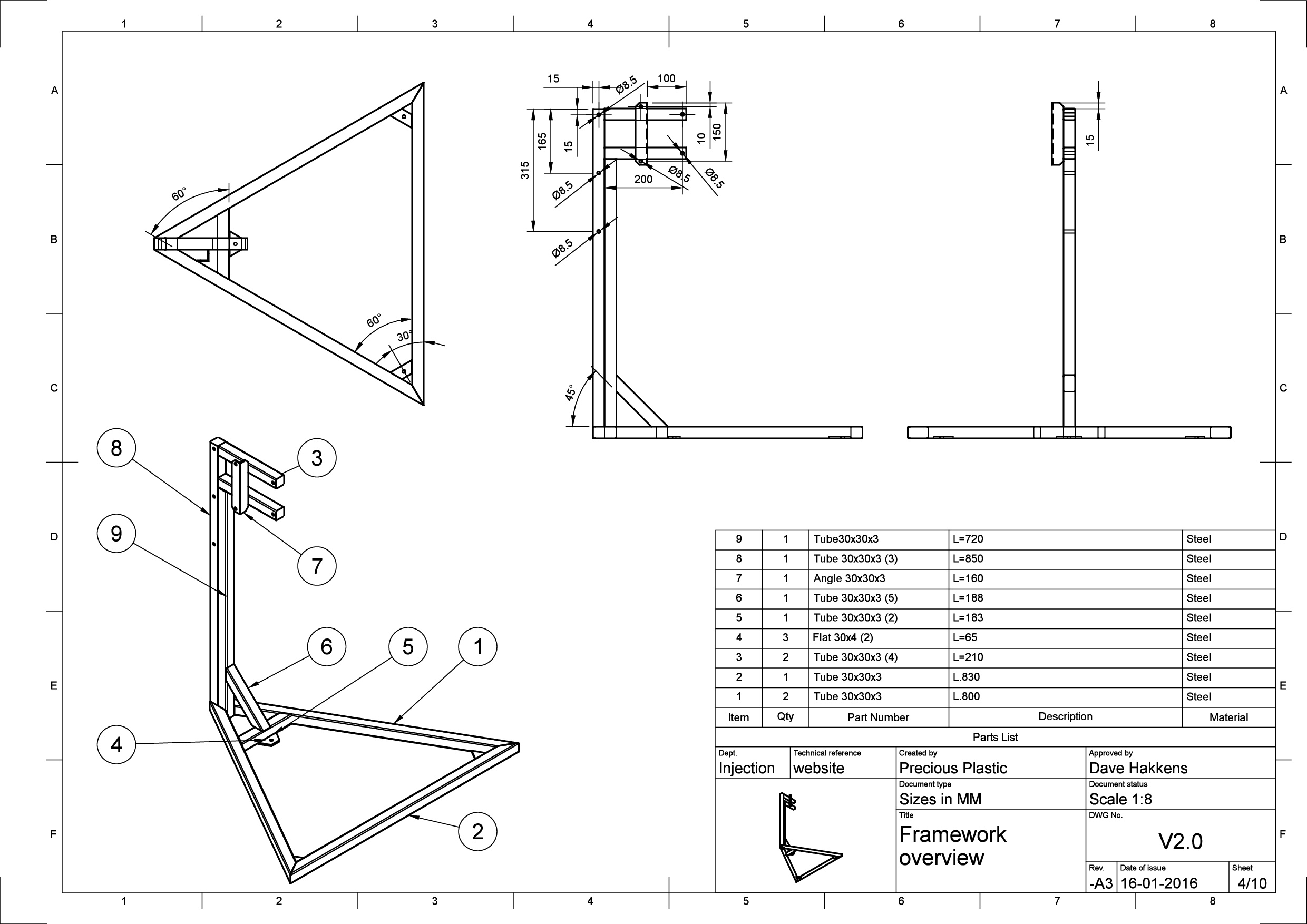

|matdesc=Framework | |matdesc=Framework | ||

|matpdffile=04 injection framework overview A3.pdf | |matpdffile=04 injection framework overview A3.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=1.1 | |matpartnumber=1.1 | ||

|matquantity=2 | |matquantity=2 | ||

| Line 50: | Line 150: | ||

|matspec=Steel, L.800 | |matspec=Steel, L.800 | ||

|matpdffile=04 injection framework overview A3.pdf | |matpdffile=04 injection framework overview A3.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=1.2 | |matpartnumber=1.2 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 57: | Line 158: | ||

|matspec=Steel, L.830 | |matspec=Steel, L.830 | ||

|matpdffile=04 injection framework overview A3.pdf | |matpdffile=04 injection framework overview A3.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=1.3 | |matpartnumber=1.3 | ||

|matquantity=2 | |matquantity=2 | ||

| Line 64: | Line 166: | ||

|matspec=Steel, L=210 | |matspec=Steel, L=210 | ||

|matpdffile=04 injection framework overview A3.pdf | |matpdffile=04 injection framework overview A3.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=1.4 | |matpartnumber=1.4 | ||

|matquantity=3 | |matquantity=3 | ||

| Line 71: | Line 174: | ||

|matspec=Steel, L=65 | |matspec=Steel, L=65 | ||

|matpdffile=04 injection framework overview A3.pdf | |matpdffile=04 injection framework overview A3.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=1.5 | |matpartnumber=1.5 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 78: | Line 182: | ||

|matspec=Steel, L=183 | |matspec=Steel, L=183 | ||

|matpdffile=04 injection framework overview A3.pdf | |matpdffile=04 injection framework overview A3.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=1.6 | |matpartnumber=1.6 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 85: | Line 190: | ||

|matspec=Steel, L=188 | |matspec=Steel, L=188 | ||

|matpdffile=04 injection framework overview A3.pdf | |matpdffile=04 injection framework overview A3.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=1.7 | |matpartnumber=1.7 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 92: | Line 198: | ||

|matspec=Steel, L=160 | |matspec=Steel, L=160 | ||

|matpdffile=04 injection framework overview A3.pdf | |matpdffile=04 injection framework overview A3.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=1.8 | |matpartnumber=1.8 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 99: | Line 206: | ||

|matspec=Steel, L=850 | |matspec=Steel, L=850 | ||

|matpdffile=04 injection framework overview A3.pdf | |matpdffile=04 injection framework overview A3.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=1.9 | |matpartnumber=1.9 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 106: | Line 214: | ||

|matspec=Steel, L=720 | |matspec=Steel, L=720 | ||

|matpdffile=04 injection framework overview A3.pdf | |matpdffile=04 injection framework overview A3.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=1.10 | |matpartnumber=1.10 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 112: | Line 221: | ||

|matspec=Wood, 18mm | |matspec=Wood, 18mm | ||

|matpdffile=08 injection framework wooden base A4.pdf | |matpdffile=08 injection framework wooden base A4.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=1.11 | |matpartnumber=1.11 | ||

|matquantity=1 | |matquantity=1 | ||

|matdesc=Framework Pullrod 2X | |matdesc=Framework Pullrod 2X | ||

|matpdffile=05 injection framework pullrod A4.pdf | |matpdffile=05 injection framework pullrod A4.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=1.12 | |matpartnumber=1.12 | ||

|matquantity=1 | |matquantity=1 | ||

|matdesc=Framework Plunger | |matdesc=Framework Plunger | ||

|matpdffile=07 injection framework plunger A4.pdf | |matpdffile=07 injection framework plunger A4.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=2 | |matpartnumber=2 | ||

|matquantity=1 | |matquantity=1 | ||

|matdesc=Framework Lever | |matdesc=Framework Lever | ||

|matpdffile=06 injection framework lever A4.pdf | |matpdffile=06 injection framework lever A4.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=2.1 | |matpartnumber=2.1 | ||

|matquantity=2 | |matquantity=2 | ||

| Line 134: | Line 247: | ||

|matspec=Steel, L.70 | |matspec=Steel, L.70 | ||

|matpdffile=06_injection framework lever A4.pdf | |matpdffile=06_injection framework lever A4.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=2.2 | |matpartnumber=2.2 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 141: | Line 255: | ||

|matspec=Steel, L.1100 | |matspec=Steel, L.1100 | ||

|matpdffile=06_injection framework lever A4.pdf | |matpdffile=06_injection framework lever A4.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=3 | |matpartnumber=3 | ||

|matquantity=1 | |matquantity=1 | ||

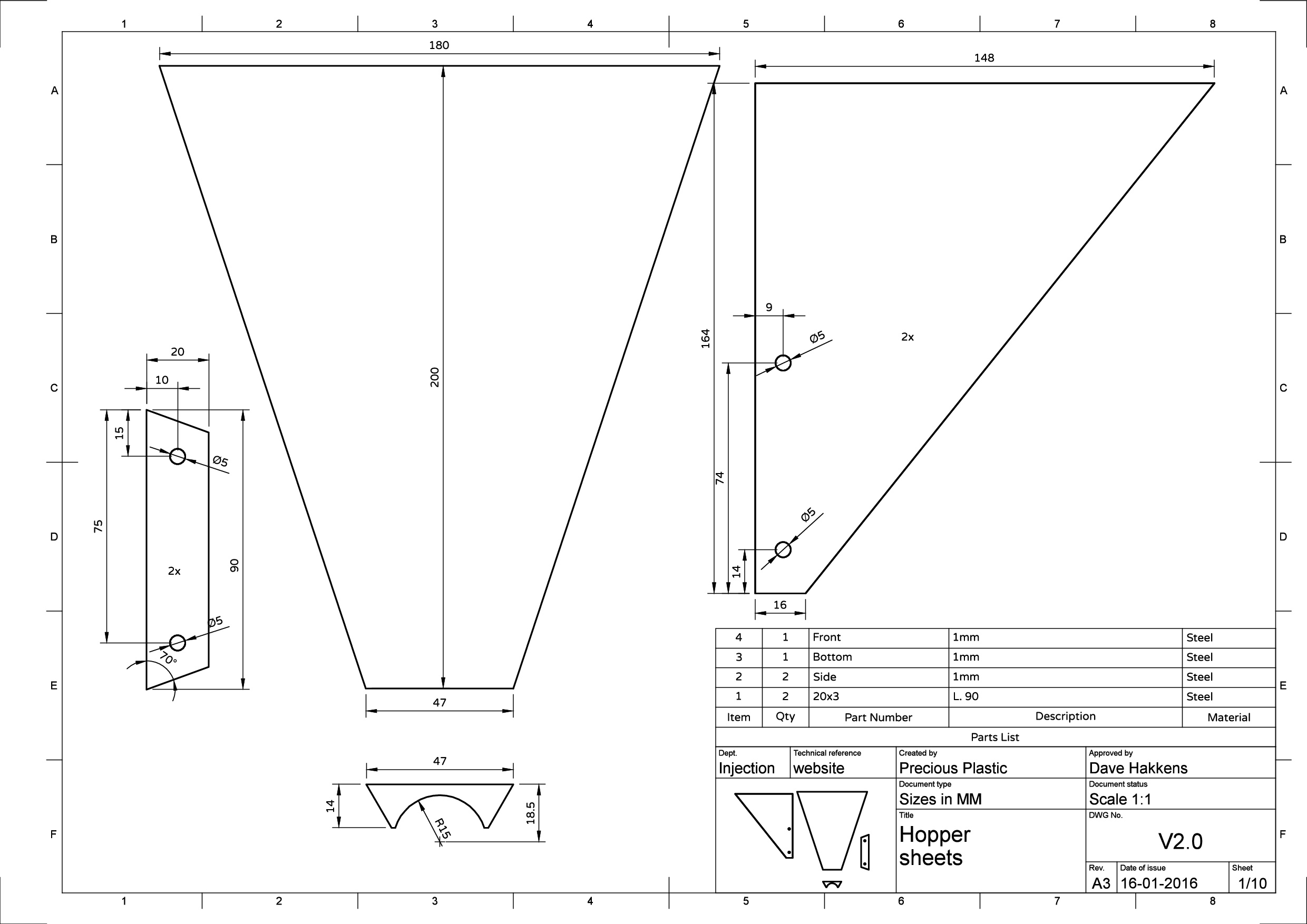

|matdesc=Hopper | |matdesc=Hopper | ||

|matpdffile=01 injection hopper A3.pdf | |matpdffile=01 injection hopper A3.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=3.1 | |matpartnumber=3.1 | ||

|matquantity=2 | |matquantity=2 | ||

| Line 153: | Line 269: | ||

|matspec=Steel, L. 90 | |matspec=Steel, L. 90 | ||

|matpdffile=03 injection barrel A4.pdf | |matpdffile=03 injection barrel A4.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=3.2 | |matpartnumber=3.2 | ||

|matquantity=2 | |matquantity=2 | ||

| Line 160: | Line 277: | ||

|matspec=Steel, 1mm | |matspec=Steel, 1mm | ||

|matpdffile=01 injection hopper A3.pdf | |matpdffile=01 injection hopper A3.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=3.3 | |matpartnumber=3.3 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 167: | Line 285: | ||

|matspec=Steel, 1mm | |matspec=Steel, 1mm | ||

|matpdffile=01 injection hopper A3.pdf | |matpdffile=01 injection hopper A3.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=3.4 | |matpartnumber=3.4 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 174: | Line 293: | ||

|matspec=Steel, 1mm | |matspec=Steel, 1mm | ||

|matpdffile=01 injection hopper A3.pdf | |matpdffile=01 injection hopper A3.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=4 | |matpartnumber=4 | ||

|matquantity=1 | |matquantity=1 | ||

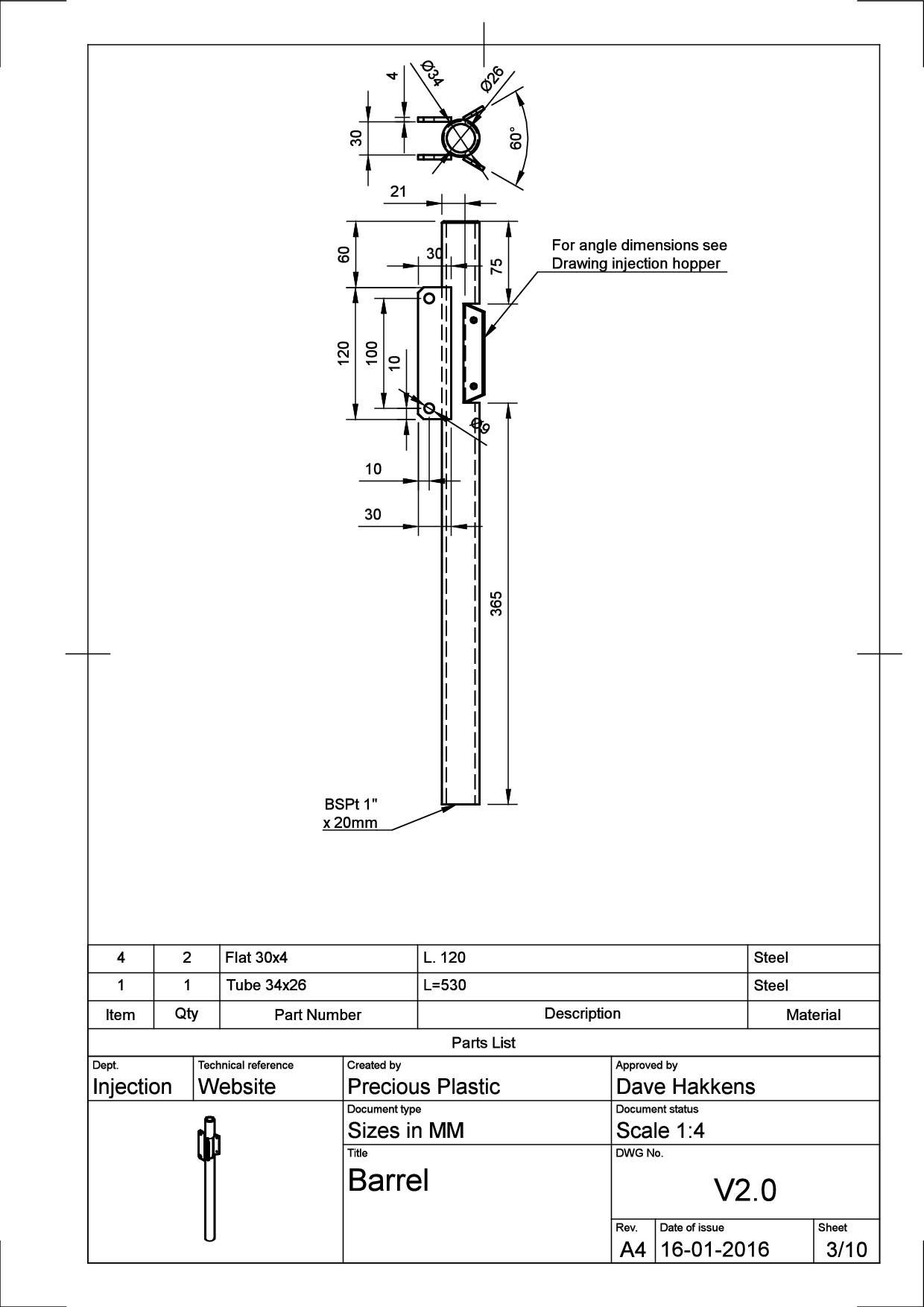

|matdesc=Barrel | |matdesc=Barrel | ||

|matpdffile=03_injection barrel A4.pdf | |matpdffile=03_injection barrel A4.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=4.1 | |matpartnumber=4.1 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 186: | Line 307: | ||

|matspec=Steel, L=530 | |matspec=Steel, L=530 | ||

|matpdffile=03_injection barrel A4.pdf | |matpdffile=03_injection barrel A4.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=4.4 | |matpartnumber=4.4 | ||

|matquantity=2 | |matquantity=2 | ||

| Line 193: | Line 315: | ||

|matspec=Steel, L=120 | |matspec=Steel, L=120 | ||

|matpdffile=03_injection barrel A4.pdf | |matpdffile=03_injection barrel A4.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=5 | |matpartnumber=5 | ||

|matquantity=1 | |matquantity=1 | ||

|matdesc=Eletronic Assembly | |matdesc=Eletronic Assembly | ||

|matpdffile=09 injection electronics assembly A4.pdf | |matpdffile=09 injection electronics assembly A4.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=5.2 | |matpartnumber=5.2 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 205: | Line 329: | ||

|matspec=Steel, Sheet 150x200x2mm | |matspec=Steel, Sheet 150x200x2mm | ||

|matpdffile=09_injection electronics assembly A4.pdf | |matpdffile=09_injection electronics assembly A4.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=5.4 | |matpartnumber=5.4 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 212: | Line 337: | ||

|matspec=Steel, 150x200x2mm | |matspec=Steel, 150x200x2mm | ||

|matpdffile=09_injection electronics assembly A4.pdf | |matpdffile=09_injection electronics assembly A4.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=5.5 | |matpartnumber=5.5 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 219: | Line 345: | ||

|matspec=Steel, 200x200x2mm | |matspec=Steel, 200x200x2mm | ||

|matpdffile=09_injection electronics assembly A4.pdf | |matpdffile=09_injection electronics assembly A4.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=5.6 | |matpartnumber=5.6 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 226: | Line 353: | ||

|matspec=Steel, 150x200x2mm | |matspec=Steel, 150x200x2mm | ||

|matpdffile=09_injection electronics assembly A4.pdf | |matpdffile=09_injection electronics assembly A4.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=5.7 | |matpartnumber=5.7 | ||

|matquantity=4 | |matquantity=4 | ||

| Line 233: | Line 361: | ||

|matspec=Steel, Flat 30x3 -45' | |matspec=Steel, Flat 30x3 -45' | ||

|matpdffile=09_injection electronics assembly A4.pdf | |matpdffile=09_injection electronics assembly A4.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=5.8 | |matpartnumber=5.8 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 240: | Line 369: | ||

|matspec=Steel, 200x200x2mm | |matspec=Steel, 200x200x2mm | ||

|matpdffile=09_injection electronics assembly A4.pdf | |matpdffile=09_injection electronics assembly A4.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=5.9 | |matpartnumber=5.9 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 247: | Line 377: | ||

|matspec=Steel, 150x200x2mm | |matspec=Steel, 150x200x2mm | ||

|matpdffile=09_injection electronics assembly A4.pdf | |matpdffile=09_injection electronics assembly A4.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=6 | |matpartnumber=6 | ||

|matquantity=1 | |matquantity=1 | ||

|matdesc=Electronic sheets | |matdesc=Electronic sheets | ||

|matpdffile=10 injection electronics sheet A3.pdf | |matpdffile=10 injection electronics sheet A3.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=6.1 | |matpartnumber=6.1 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 259: | Line 391: | ||

|matspec=Steel, 150x200x2mm | |matspec=Steel, 150x200x2mm | ||

|matpdffile=10_injection electronics sheet A3.pdf | |matpdffile=10_injection electronics sheet A3.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=6.2 | |matpartnumber=6.2 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 266: | Line 399: | ||

|matspec=Steel, 200x200x2mm | |matspec=Steel, 200x200x2mm | ||

|matpdffile=10_injection electronics sheet A3.pdf | |matpdffile=10_injection electronics sheet A3.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=6.3 | |matpartnumber=6.3 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 273: | Line 407: | ||

|matspec=Steel, Sheet 150x200x2mm | |matspec=Steel, Sheet 150x200x2mm | ||

|matpdffile=10_injection electronics sheet A3.pdf | |matpdffile=10_injection electronics sheet A3.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=6.4 | |matpartnumber=6.4 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 280: | Line 415: | ||

|matspec=Steel, Flat 30x3-45' | |matspec=Steel, Flat 30x3-45' | ||

|matpdffile=10_injection electronics sheet A3.pdf | |matpdffile=10_injection electronics sheet A3.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=6.5 | |matpartnumber=6.5 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 287: | Line 423: | ||

|matspec=Steel, 150x200x2mm | |matspec=Steel, 150x200x2mm | ||

|matpdffile=10_injection electronics sheet A3.pdf | |matpdffile=10_injection electronics sheet A3.pdf | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=7 | |matpartnumber=7 | ||

|matquantity=1 | |matquantity=1 | ||

|matdesc=Electronics | |matdesc=Electronics | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=7.1 | |matpartnumber=7.1 | ||

|matquantity=2 | |matquantity=2 | ||

|matdesc=PID Controller | |matdesc=PID Controller | ||

|matspec=0-400 Degree | |matspec=0-400 Degree | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=7.2 | |matpartnumber=7.2 | ||

|matquantity=2 | |matquantity=2 | ||

|matdesc=SSR | |matdesc=SSR | ||

|matspec=2-24 V | |matspec=2-24 V | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=7.3 | |matpartnumber=7.3 | ||

|matquantity=2 | |matquantity=2 | ||

|matdesc=Thermocouple | |matdesc=Thermocouple | ||

|matspec=Type K | |matspec=Type K | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=7.4 | |matpartnumber=7.4 | ||

|matquantity=4 | |matquantity=4 | ||

|matdesc=Bandheater | |matdesc=Bandheater | ||

|matspec=metal, 35x45MM | |matspec=metal, 35x45MM | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=7.5 | |matpartnumber=7.5 | ||

|matquantity=1 | |matquantity=1 | ||

|matdesc=Power switch | |matdesc=Power switch | ||

|matspec=220V | |matspec=220V | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=7.6 | |matpartnumber=7.6 | ||

|matquantity=1 | |matquantity=1 | ||

|matdesc=Led indicator | |matdesc=Led indicator | ||

|matspec=220V | |matspec=220V | ||

}}{{ProjektMaterials | }} | ||

{{ProjektMaterials | |||

|matpartnumber=7.7 | |matpartnumber=7.7 | ||

|matquantity=5m | |matquantity=5m | ||

Latest revision as of 20:24, 21 April 2023

Project data

|

Category: Plastic production URL (first publication): https://community.preciousplastic.com/academy/build/injection License: CC BY-NC-SA 4.0 Organization: Precious Plastic Project status: Active Certification status: In process

Maturity of the project: production / full product

Contains PDF-drawings: Yes CAD files are editable: Yes Bill of materials is published: Yes

no no

|

|

Project details

Description

In order to develop a homemade machine, capable of making parts by injection of recycled plastic, this project is presented, developed by the Precious Plastic organization (P.P.), where a device is manufactured from reused iron parts and some electrical components, efficient for this purpose. Details of the original development are on the P.P. website.

Technical data

Some features of the machine:

- Type: Injection

- Version: 1.0

- Weight: 23 kg

- Dimensions: 830 x 700 x 1300 mm

- Barrel volume: 150 cm³

- Leverage: 3

- Injection pressure: 45 bars

- Max mould size: 360 x 330 mm

- Injections p/h: 10 - 30

- Voltage: 220V

- AMP: 2.6A

- Input Flake Size: Medium, Small

- Temperature control: PID Controller, Solid State Relay and Thermocouple

- Processed material: HDPE, LDPE, PP, PS

- Output: 10-30 injections per hour depending on mould

Technical documentation

Plastic injection machine - CAD-files

Plastic injection machine - bill of materials

Other technical notes

Tips & tricks while making

- Take care welding around the hopper tabs. The heat can easily distort the barrel, ruining that perfect slide.

- Adding an insulated barrel cover will increase efficiency and reduce the chances of the user accidentally touching the barrel when hot.

- When building, the lever is stronger as a circular profile when compared to a square profile. Which will reduce the likelihood of bending it.

Assembly instructions

Here are some plans with the assembly sets and pieces, which can be detailed at this link

Tests, practical applications

It can be seen that the machine can produce injected parts from recycled plastic, see this point in the video.

+ General Reviews

Reviews

| Pos. | Qty. | Part Name | Part code | Part Type | Specifications | Review Status | Show All Comments | |

|---|---|---|---|---|---|---|---|---|

| 1 | 1 | Framework | ||||||

| 1.1 | 2 | Tube 30x30x3 | 1 | Steel, L.800 | ||||

| 1.2 | 1 | Tube 30x30x3 | 2 | Steel, L.830 | ||||

| 1.3 | 2 | Tube 30x30x3 (4) | 3 | Steel, L=210 | ||||

| 1.4 | 3 | Flat 30x4 (2) | 4 | Steel, L=65 | ||||

| 1.5 | 1 | Tube 30x30x3 (2) | 5 | Steel, L=183 | ||||

| 1.6 | 1 | Tube 30x30x3 (5) | 6 | Steel, L=188 | ||||

| 1.7 | 1 | Angle 30x30x3 | 7 | Steel, L=160 | ||||

| 1.8 | 1 | Tube 30x30x3 (3) | 8 | Steel, L=850 | ||||

| 1.9 | 1 | Tube30x30x3 | 9 | Steel, L=720 | ||||

| 1.10 | 1 | Framework Wooden base | Wood, 18mm | |||||

| 1.11 | 1 | Framework Pullrod 2X | ||||||

| 1.12 | 1 | Framework Plunger | ||||||

| 2 | 1 | Framework Lever | ||||||

| 2.1 | 2 | Flat 30x4(1) | 1 | Steel, L.70 | ||||

| 2.2 | 1 | Tube 30x30x3 (1) | 2 | Steel, L.1100 | ||||

| 3 | 1 | Hopper | ||||||

| 3.1 | 2 | 20x3 | 1 | Steel, L. 90 | ||||

| 3.2 | 2 | Side | 2 | Steel, 1mm | ||||

| 3.3 | 1 | Bottom | 3 | Steel, 1mm | ||||

| 3.4 | 1 | Front | 4 | Steel, 1mm | ||||

| 4 | 1 | Barrel | ||||||

| 4.1 | 1 | Tube 34x26 | 1 | Steel, L=530 | ||||

| 4.4 | 2 | Flat 30x4 | 4 | Steel, L=120 | ||||

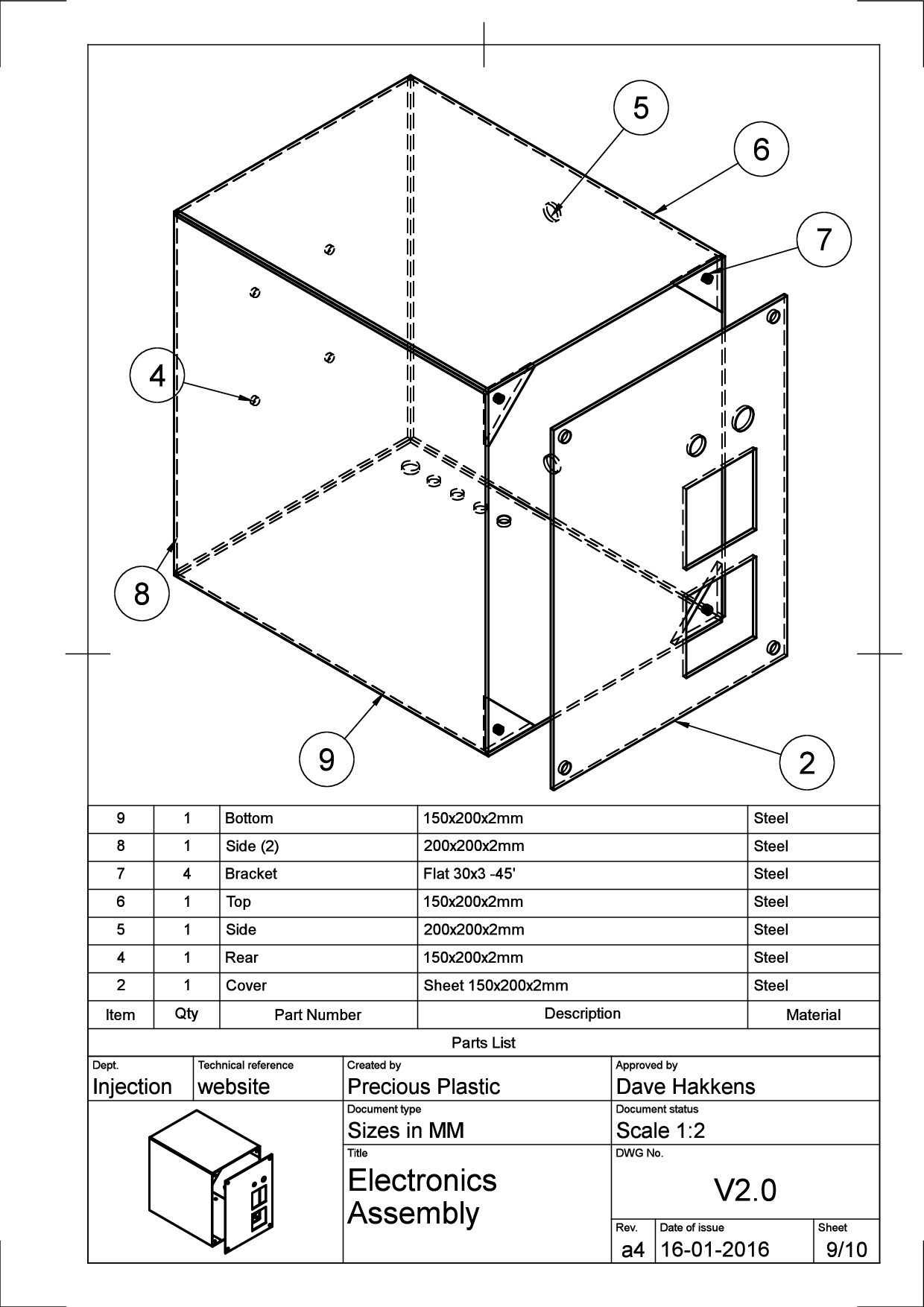

| 5 | 1 | Eletronic Assembly | ||||||

| 5.2 | 1 | Cover | 2 | Steel, Sheet 150x200x2mm | ||||

| 5.4 | 1 | Rear | 4 | Steel, 150x200x2mm | ||||

| 5.5 | 1 | Side | 5 | Steel, 200x200x2mm | ||||

| 5.6 | 1 | Top | 6 | Steel, 150x200x2mm | ||||

| 5.7 | 4 | Bracket | 7 | Steel, Flat 30x3 -45' | ||||

| 5.8 | 1 | Side (2) | 8 | Steel, 200x200x2mm | ||||

| 5.9 | 1 | Bottom | g | Steel, 150x200x2mm | ||||

| 6 | 1 | Electronic sheets | ||||||

| 6.1 | 1 | Rear(1) | 1 | Steel, 150x200x2mm | ||||

| 6.2 | 1 | Side (3) | 2 | Steel, 200x200x2mm | ||||

| 6.3 | 1 | Cover (1) | 3 | Steel, Sheet 150x200x2mm | ||||

| 6.4 | 1 | Bracket (1) | 4 | Steel, Flat 30x3-45' | ||||

| 6.5 | 1 | Bottom (2) | 5 | Steel, 150x200x2mm | ||||

| 7 | 1 | Electronics | ||||||

| 7.1 | 2 | PID Controller | 0-400 Degree | |||||

| 7.2 | 2 | SSR | 2-24 V | |||||

| 7.3 | 2 | Thermocouple | Type K | |||||

| 7.4 | 4 | Bandheater | metal, 35x45MM | |||||

| 7.5 | 1 | Power switch | 220V | |||||

| 7.6 | 1 | Led indicator | 220V | |||||

| 7.7 | 5m | Powercord | 30x30x3mm | |||||