Difference between revisions of "Plastic extrusion machine, Precious Plastic"

Inddigital (talk | contribs) ((by SublimeText.Mediawiker)) |

Inddigital (talk | contribs) ((by SublimeText.Mediawiker)) |

||

| Line 173: | Line 173: | ||

</div> | </div> | ||

}} | }} | ||

|TechDoc={{ProjektComponent | |TechDoc={{ProjektComponent | ||

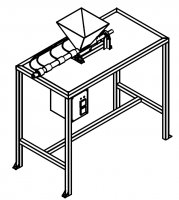

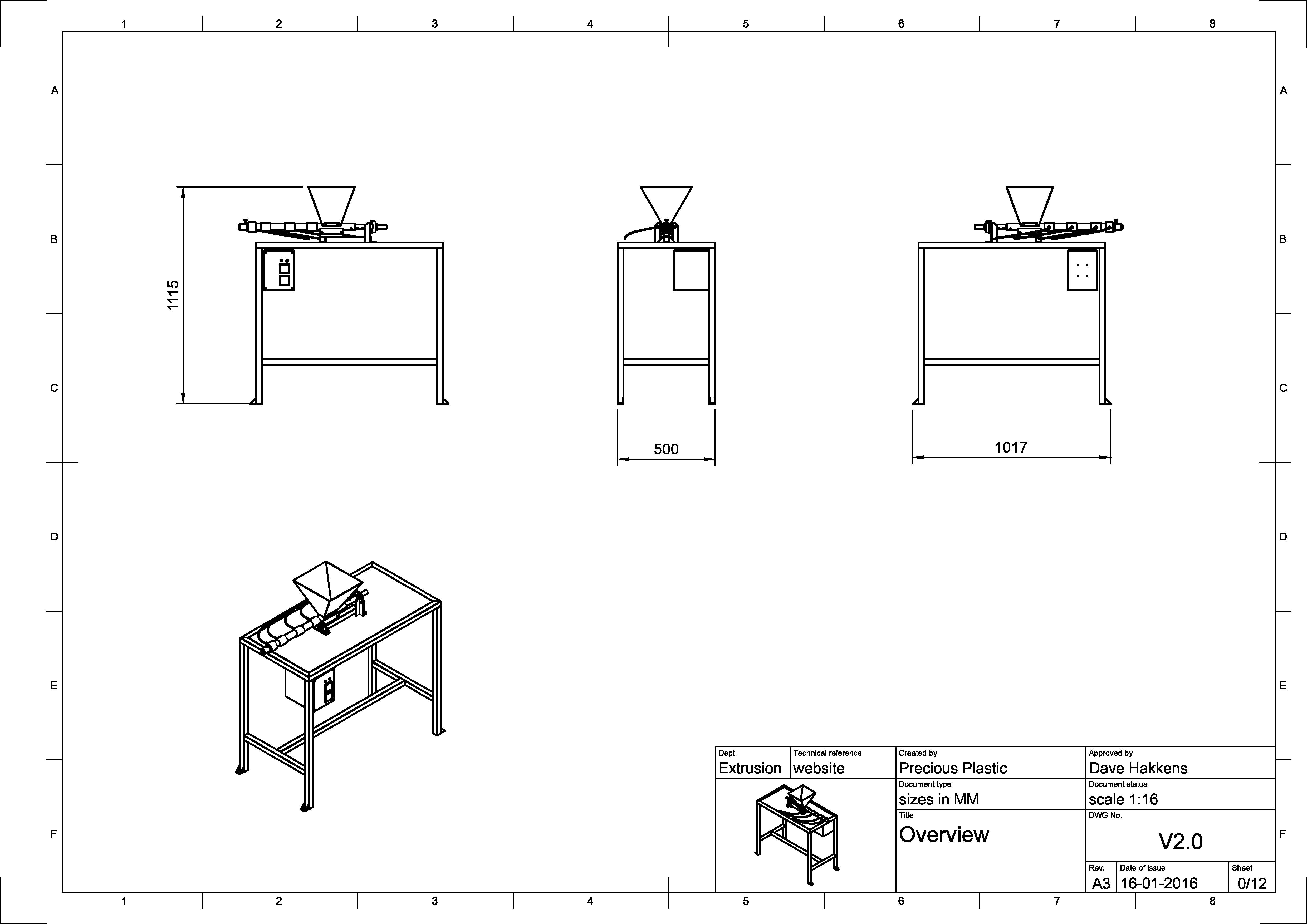

|cmpimage=precious-p-Extrusion_all_p1.jpg | |||

|cmptitle=<h3 style="font-size: 19px; padding-top: 0px;">Plastic extrusion machine - all drawings</h3> | |cmptitle=<h3 style="font-size: 19px; padding-top: 0px;">Plastic extrusion machine - all drawings</h3> | ||

|cmpfile1=Extrusion all.pdf | |cmpfile1=Extrusion all.pdf | ||

| Line 184: | Line 186: | ||

<div style="margin:20px"></div> | <div style="margin:20px"></div> | ||

{{ProjektComponent | {{ProjektComponent | ||

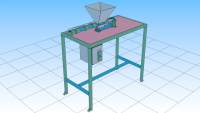

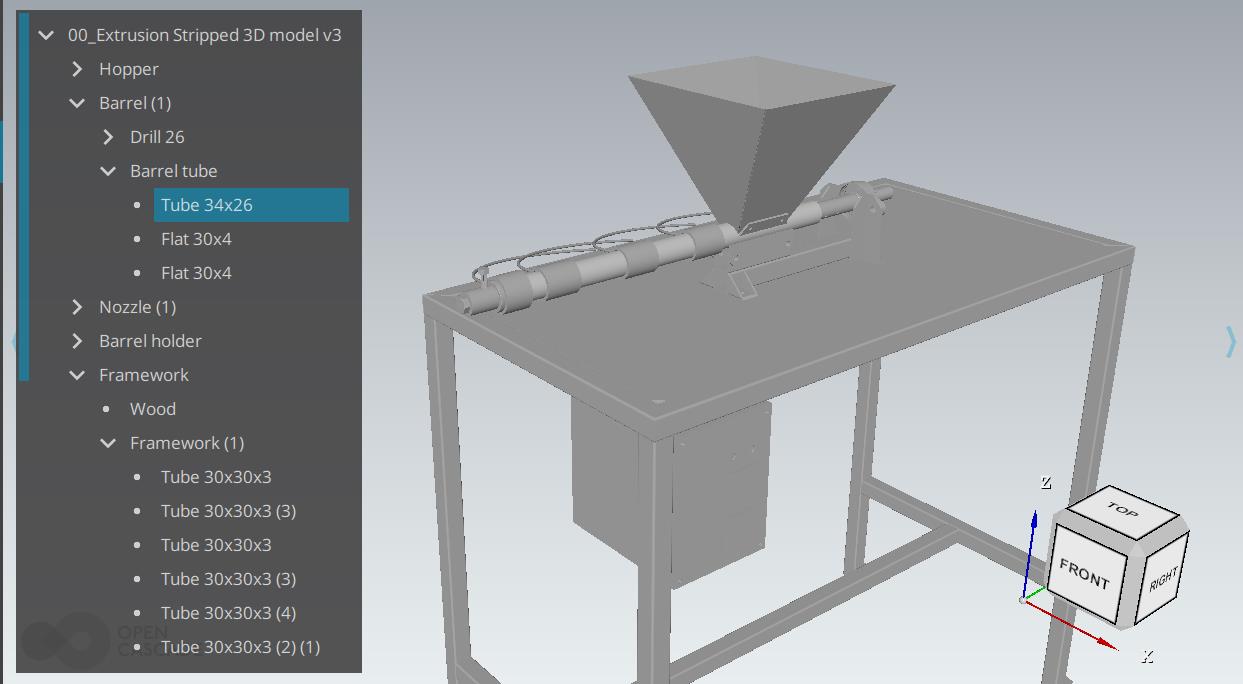

|cmpimage=precious-p-view1.jpg | |||

|cmptitle=<h3 style="font-size: 19px; padding-top: 0px;">Plastic extrusion machine - CAD-files</h3> | |cmptitle=<h3 style="font-size: 19px; padding-top: 0px;">Plastic extrusion machine - CAD-files</h3> | ||

|cmpfile1=Extrusion V2.0 CAD.iges | |cmpfile1=Extrusion V2.0 CAD.iges | ||

Revision as of 04:50, 13 April 2023

Project data

|

Category: Extrusion machines URL (first publication): https://community.preciousplastic.com/academy/build/extrusion License: CC BY-SA 4.0 Organization: Precious Plastic Project status: Active Certification status: In process

Maturity of the project: production / full product

Contains PDF-drawings: Yes CAD files are editable: Yes Assembly instructions are published: Yes Bill of materials is published: Yes

no no

|

|

Project details

| |

| This project has been analyzed by the OHO technical team, based on an extensive review of similar technical solutions, planned by various entrepreneurs and enthusiasts, taking the work of developer Precious Plastic, as the main reference for further developments. | |

| |

Among some of the objectives set in the realization of this project, we can mention:

| |

| |

This project is mainly aimed at people and small businesses that work with plastic processing in the production of non-industrialized goods, oriented towards community development and sustainable production, among these we can mention:

| |

| |

|

From the publication of this project, by Precious Plastic, an interesting dynamic has been generated on its YouTube channel, where it was widely accepted by technicians and academics interested in building the machine. Additionally, on the project page, a group of initiatives is shown where the equipment could be built with some variants. |

| |

|

This project can help advance several Sustainable Development Goals (SDGs) in various ways:

Overall, the design and manufacture of a DIY recycled plastic extruder can contribute to several Sustainable Development Goals, promoting sustainable infrastructure, responsible consumption and production, climate action, and the protection of our natural ecosystems. |

| ||||||||||||||

| ||||||||||||||

| ||||||||||||

| ||||||||||||

Technical documentation

| |

|

|

Files: | |

| |

Files: | |

| |

|

|

Files: | |

+ General Reviews

Reviews

| Pos. | Qty. | Part Name | Part code | Part Type | Specifications | Review Status | Show All Comments | |

|---|---|---|---|---|---|---|---|---|

| 0 | Plastic extrusion machine | |||||||

| 1 | 1 | Framework | ||||||

| 1.1 | 2 | Tube 30x30x3 | Steel, L=960 | |||||

| 1.2 | 2 | Tube 30x30x3 (3) | Steel, L=500 | |||||

| 1.3 | 4 | Tube 30x30x3 (4) | Steel, L=800 | |||||

| 1.4 | 4 | Tube 30x30x3 (2) (1) | Steel, L=35 | |||||

| 1.5 | 2 | Tube 30x30x3 (5) | Steel, L=440 | |||||

| 1.6 | 1 | Tube 30x30x3 (6) | Steel, L=900 | |||||

| 1.7 | 4 | Flat 30x3 | Steel, L=100 | |||||

| 2 | 1 | Hopper | ||||||

| 2.1 | 2 | Front | Steel, Sheet 1 mm | |||||

| 2.2 | 2 | Flat 20x3 | Steel, L=90 | |||||

| 2.3 | 2 | Side (1) (1) | Steel, I Sheet 1mm | |||||

| 3 | 1 | Barrelholder | ||||||

| 3.1 | 2 | Tube 30x30x3 (2) | ||||||

| 3.2 | 1 | Tube 30x30x3 (1) | Steel, L=260 | |||||

| 3.3 | 1 | Tube 30x30x3 | Steel, L=120 | |||||

| 3.4 | 1 | Angle 30x3 | Steel, L=120 | |||||

| 3.5 | 1 | Angle 30x3(1) | Steel, L=100 | |||||

| 3.6 | 1 | Angle 30x3 (2) | Steel, L=100 | |||||

| 3.7 | 1 | Barrelholder bearing shaft | ||||||

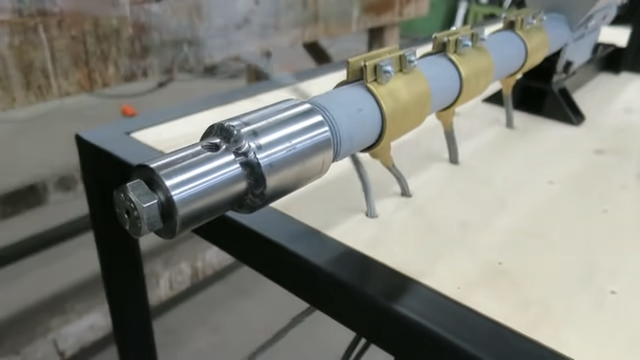

| 4 | 1 | Barrel | ||||||

| 4.1 | 1 | Tube 34x26 | Steel, L=530 | |||||

| 4.4 | 2 | Flat 30x4 | Steel, L=120 | |||||

| 5 | 1 | Nozzle | ||||||

| 5.1 | 1 | Nozzle flow adjuster 1" BSPfitting Female | Steel | |||||

| 5.2 | 1 | Nozzle filter, Filter Alu R.30 | Aluminum, L=4 | |||||

| 5.4 | 1 | Nozzle screw | Steel, M12xl0 | |||||

| 5.5 | 1 | Round 30 | Steel, L=55 | |||||

| 5.6 | 1 | M8x30 | Steel | |||||

| 6 | 1 | Electronic metal box | ||||||

| 6.2 | 1 | Cover | Steel, Sheet 150x200x2mm | |||||

| 6.4 | 1 | Rear | Steel, 150x200x2mm | |||||

| 6.5 | 1 | Side | Steel, 200x200x2mm | |||||

| 6.6 | 1 | Top | Steel, 150x200x2mm | |||||

| 6.7 | 4 | Bracket | Steel, Flat 30x3 -45' | |||||

| 6.8 | 1 | Side (2) | Steel, 200x200x2mm | |||||

| 6.9 | 1 | Bottom | Steel, 150x200x2mm | |||||

| 7 | 1 | Electronic sheets | ||||||

| 7.1 | 1 | Rear(1) | Steel, 150x200x2mm | |||||

| 7.2 | 1 | Side (3) | Steel, 200x200x2mm | |||||

| 7.3 | 1 | Cover (1) | Steel, Sheet 150x200x2mm | |||||

| 7.4 | 1 | Bracket (1) | Steel, Flat 30x3-45' | |||||

| 7.5 | 1 | Bottom (2) | Steel, 150x200x2mm | |||||

| 8 | 1 | Buy parts | ||||||

| 8.1 | 1 | Motor | Around 70 RPM | |||||

| 8.2 | 1 | Bearing | UCFL204 | |||||

| 8.3 | 1 | Drill | 26 x 600 MM (make sure if fits the tube) | |||||

| 8.4 | 1 | Electronics | ||||||

| 8.5 | 2 | PID Controller | 0-400 Degree | |||||

| 8.6 | 2 | SSR | 2-24 V | |||||

| 8.7 | 2 | Thermocouple | Type K | |||||

| 8.8 | 3 | Bandheater | 35x45MM | |||||

| 8.9 | 1 | Bandheater | 40x45 MM | |||||

| 8.10 | 1 | Power switch | 220V | |||||

| 8.11 | 1 | Led indicator | 220V | |||||

| 8.12 | 5m | Powercord | ||||||