Based on the DIN 2221 standard, among others, OHO has established a series of stages in which the satisfactory completion of this project was carried out

1. Feasibility study

-

Materials, components

Required materials & components can be sourced or replaced locally?

✓ Yes

All the materials can be located with some ease, in hardware stores, parts stores and/or junkyards

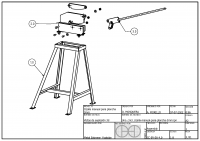

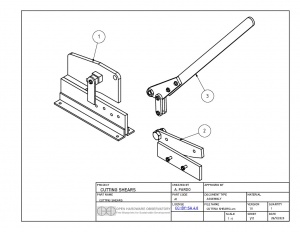

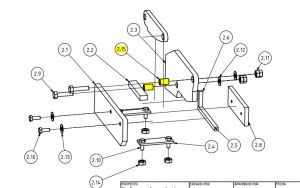

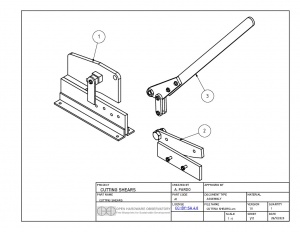

Previous theoretical case, showing the exploded view

-

Manufacturing processes

Required manufacturing processes can be povided locally?

✓ Yes

In a small workshop, all the processes required for manufacturing can be achieved

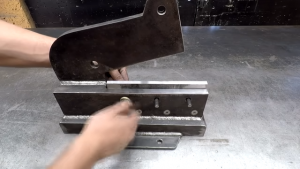

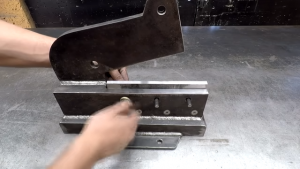

Example showing the processes involved

-

Specific training

Is specific training for manufacturing necessary and can be provided?

✓ Yes

Especially when it comes to heat treatment for the blades

-

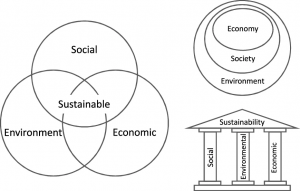

Sustainability

Do all materials and processes meet the sustainability criteria?

✓ Yes

It is observed that both the materials used and the manufacturing processes are sustainable from an economic, social and environmental point of view

2. Market analisis and requirements

-

Market analysis

Analysis of the current products on the market:

* Price [USD]: 237

* Source: ebay

* Country: USA

* Price [USD]: 243

* Source: ebay

* Country: USA

* Price [USD]: 100

* Source: mercadolibre

* Country: Venezuela

* Price [USD]: 363

* Source: mercadolibre

* Country: Venezuela

-

Requirements definition

Definition of the main technical data (size, capacity, power...):

- Maximum sheet thickness [mm]: 3

- Maximum round bar diameter [mm]: 13

- Maximum plate or angle thickness [mm]: 5

- Cutting length [mm]: 150-180

-

Optimal functions and features:

Definition of necessary/optional functions and features

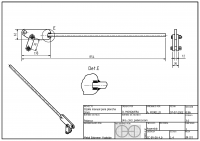

- High hardness steel blade: Shear is required to have hardened steel blades

- To screw on a metal bench: It is preferred that the machine includes its own support structure

3. Search & analisis DIY technologies

-

OHO Search engine

Customization of the OHO search engine

A search for similar or related equipment was carried out in our repository, obtaining some equipment that can be used as a reference

-

Manual search

Searches were also performed within Google, Youtube, special websites etc., getting, among others, the following results:

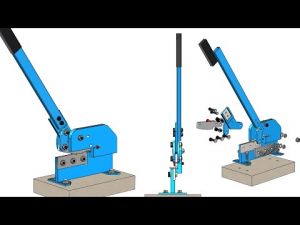

* Title: Homemade shears for sheet cutting

* Views: 280000

* Likes: 4900

* Comments: 285

* Maximum sheet thickness [mm]: 3

* Maximum thickness of plate [mm]: 3

* Cutting length [mm]: 205

* High hardness steel blade: Yes

* To screw on a metal bench: Yes

This example will be used as the main reference machine

* Title: Leaf Spring HACK - Metal Cutter

* Views: 486000

* Likes: 5800

* Comments: 162

* Maximum sheet thickness [mm]: 2.5

* Maximum thickness of plate [mm]: 2.5

* Cutting length [mm]: 200

* High hardness steel blade: Yes

* To screw on a metal bench: Yes

* Title: Homemade metal shear

* Views: 331000

* Likes: 3200

* Comments: 123

* Maximum sheet thickness [mm]: 3

* Maximum thickness of plate [mm]: 3

* Cutting length [mm]: 130

* High hardness steel blade: Yes

* To screw on a metal bench: Yes

* Title: Manual Sheet Shear

* Views: 236000

* Likes: 4600

* Comments: 215

* Maximum sheet thickness [mm]: 3.6

* Cutting length [mm]: 200

* High hardness steel blade: Yes

* To screw on a metal bench: Yes

-

Networking

This section refers to contacting partners, associated organizations and experts

Since the cases found on the internet provide enough information, it was not necessary to search for reference equipment in this way, it can be useful when working with unusual equipments

4. Development & documentation

-

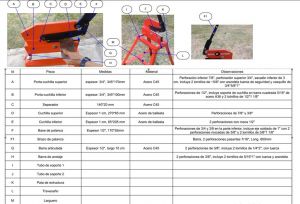

Analisis of functions & structures

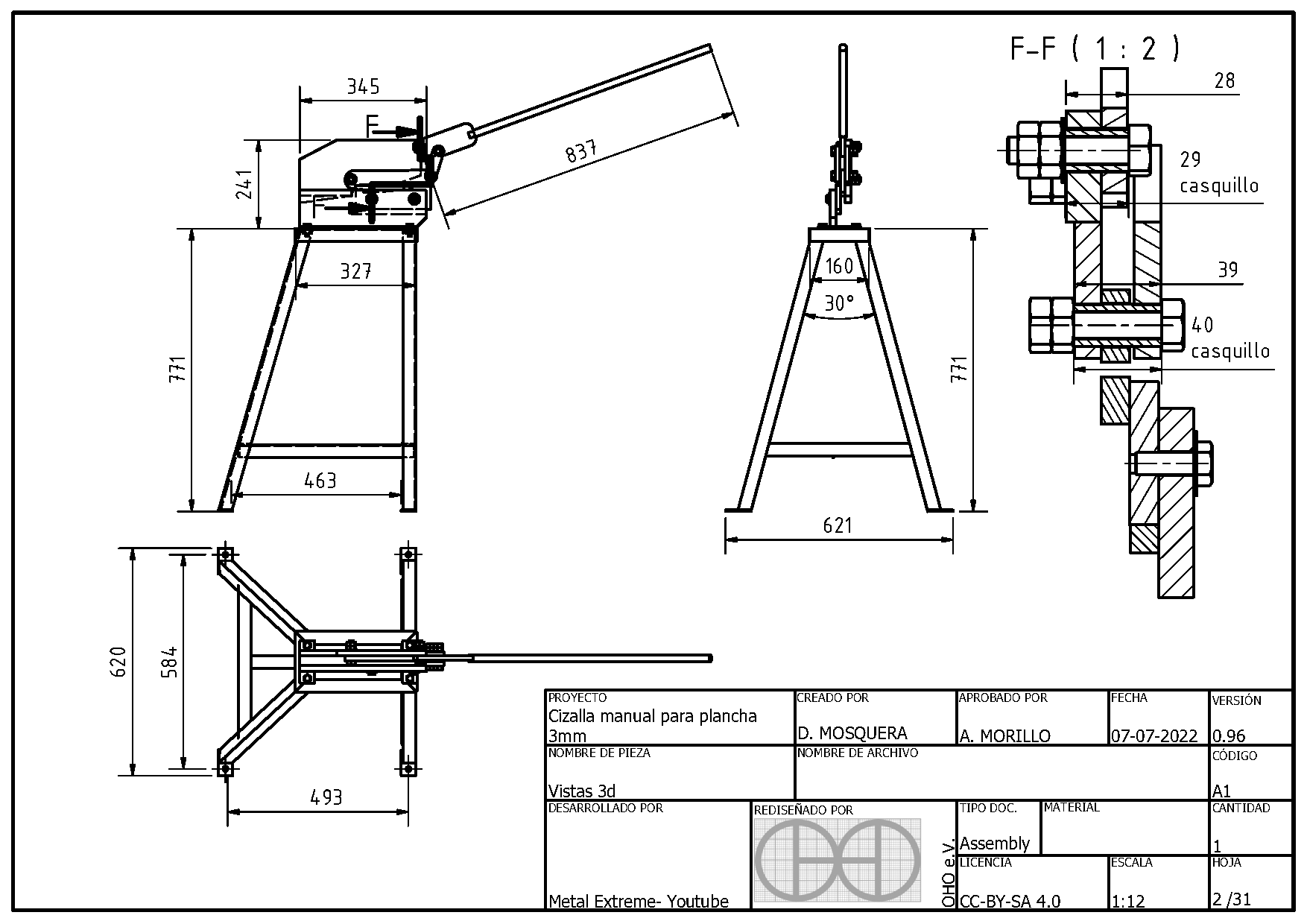

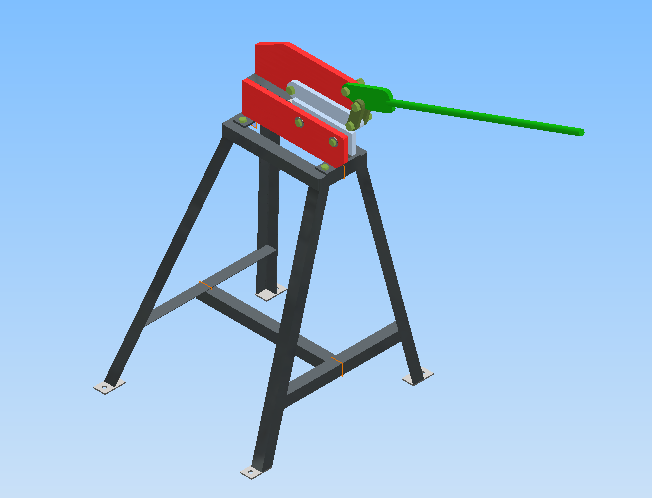

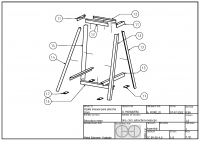

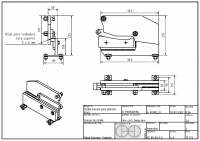

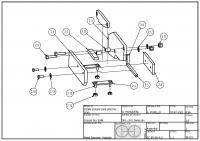

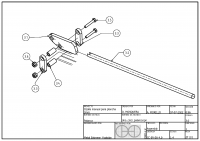

From analyzing the operation and parts of the main reference machine and the rest of the examples obtained, a first list of components for the shear is generated

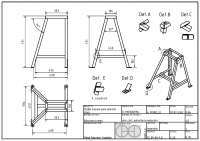

During this process, some measurements of the parts and assemblies, essential for the design, are extracted

-

Technical solutions

The OHO development team also proceeds to design and determine the engineering problems that arise, in order to obtain a quality product that can be manufactured with Appropriate Technologies

One of the solutions generated by the technical team was the inclusion of some bushings in the joints, this to ensure that these joints do not get stuck and enough tightening to support the loads

-

Technical documentation

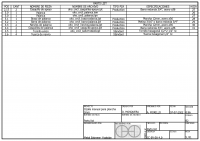

There is an internal and self-managed Gitlab repository, where the preparation of plans, exploded views, the final parts list, details and annotations, among others, are controlled at a formal and technical level

-

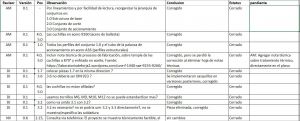

Peer-Reviews

Before continuing with manufacturing, a group of experts was convened to verify the plans and generate observations, in order to optimize the design and prevent errors during later stages

5. Manufacturing, tests, improvement

- Determination of the workshop for manufacturing:

- Among the most important aspects to be fulfilled by the manufacturing workshop, we have:

- It does not require industrial or specialized processes such as plastic processing, CNC machining, complex chemical processes, among others

- It has basic tools for working with metal and wood at a non-industrial level

- It has measuring instruments appropriate to the processes, such as: vernier, tape measure, thread counter, gauges, etc.

- Includes painting equipment such as compressor and spray gun

- It is a space large enough and ordered for manufacturing, assembly and painting operations

- It has qualified personnel in basic and intermediate works with metal, wood, painting, among others

- Some parts or processes that are not available may be purchased or ordered from more specialized stores and workshops

- Purchase

- Purchase of materials and components:

- Manufacturing of prototype

- Fabrication according to specified quality standards:

- Module tests, system tests, improvement of components:

- Updates of technical documentation

- Updates of plans, parts lists, assembly instructions:

|