Difference between revisions of "Manual shearing machine for 3mm plate"

Inddigital (talk | contribs) ((by SublimeText.Mediawiker)) |

Inddigital (talk | contribs) ((by SublimeText.Mediawiker)) |

||

| (329 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

{{ | {{Projekt2 | ||

|Images={{ProjektImages | |Images= | ||

{{ProjektImages | |||

|projectimage=Oho cm3 foto1.jpg | |projectimage=Oho cm3 foto1.jpg | ||

}}{{ProjektImages | }} | ||

{{ProjektImages | |||

|projectimage=Oho cm3 001.png | |projectimage=Oho cm3 001.png | ||

}}{{ProjektImages | }} | ||

{{ProjektImages | |||

|projectimage=Oho cm3 002.png | |projectimage=Oho cm3 002.png | ||

}}{{ProjektImages | }} | ||

{{ProjektImages | |||

|projectimage=oho_cm3oho_cizalla-manual-fabricación_1.02.mp4_snapshot_05.37.jpg | |||

}} | |||

{{ProjektImages | |||

|projectimage=oho_cm3oho_cizalla-manual-fabricación_1.02.mp4_snapshot_06.03.jpg | |||

}} | |||

{{ProjektImages | |||

|projectimage=Oho cm3 003.png | |projectimage=Oho cm3 003.png | ||

}}{{ProjektImages | }} | ||

{{ProjektImages | |||

|projectimage=Oho cm3 004.png | |projectimage=Oho cm3 004.png | ||

}}{{ProjektImages | }} | ||

{{ProjektImages | |||

|projectimage=Oho cm3 005.png | |projectimage=Oho cm3 005.png | ||

}}{{ProjektImages | }} | ||

{{ProjektImages | |||

|projectimage=Oho cm3 006.png | |projectimage=Oho cm3 006.png | ||

}}{{ProjektImages | }} | ||

{{ProjektImages | |||

|projectimage=Oho cm3 007.png | |projectimage=Oho cm3 007.png | ||

}}{{ProjektImages | }} | ||

{{ProjektImages | |||

|projectimage=Oho cm3 015.png | |projectimage=Oho cm3 015.png | ||

}}{{ProjektImages | }} | ||

{{ProjektImages | |||

|projectimage=Oho cm3 016.png | |projectimage=Oho cm3 016.png | ||

}}{{ProjektImages | }} | ||

{{ProjektImages | |||

|projectimage=Oho cm3 026.png | |projectimage=Oho cm3 026.png | ||

}}{{ProjektImages | }} | ||

{{ProjektImages | |||

|projectimage=Oho cm3 027.png | |projectimage=Oho cm3 027.png | ||

}} | }} | ||

| Line 32: | Line 50: | ||

|firstin=https://www.youtube.com/watch?v=Oz5MzN0Pc_M | |firstin=https://www.youtube.com/watch?v=Oz5MzN0Pc_M | ||

|trans_status=WT | |trans_status=WT | ||

|licence=CCBYNCSA40 | |licence=CCBYNCSA40 | ||

|typeproject=Youtube | |typeproject=Youtube | ||

| Line 49: | Line 66: | ||

|versioning_system=yes | |versioning_system=yes | ||

|contains_pdf_drawings=yes | |contains_pdf_drawings=yes | ||

|technology_readyness_level= | |technology_readyness_level=6 | ||

|TechDoc={{ | |Desc= | ||

{{ProjektComponent2 | |||

|cmptitle=Description | |||

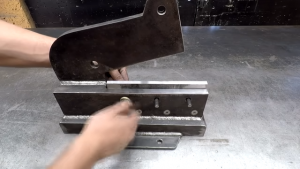

|cmpimage=oho_cm3oho_cizalla-manual-fabricación_1.02.mp4_snapshot_05.37.jpg | |||

|cmpimg= | |||

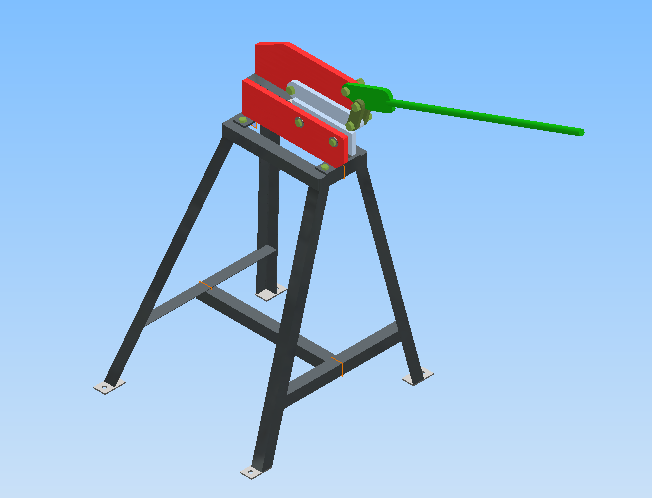

The cutting shears boast a robust design made possible through thorough research of online videos and incorporation of repurposed car leaf springs that underwent a heat treatment. The end result is a durable yet environmentally conscious tool capable of handling challenging metal cutting tasks with ease. | |||

}} | |||

<div style="margin:20px"></div> | |||

{{ProjektComponent2 | |||

|cmptitle= Technical data | |||

|cmpimg= | |||

Below are some features of the manufactured shears: | |||

* Maximum sheet thickness: 3mm | |||

* Maximum round bar diameter: 13mm | |||

* Maximum plate or angle thickness: 5mm | |||

* Cutting length: 180mm | |||

* Dimensions: Length: 0.6m x Width: 0.6m x Height: 1m | |||

* Weight: Approximately 23 kg | |||

* Blade Type: Hardened 9260 steel | |||

* Drive: Manual lever | |||

}} | |||

|TechDoc= | |||

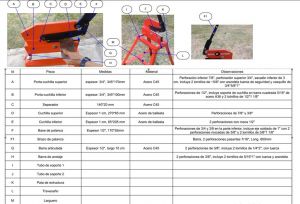

{{ProjektComponent2 | |||

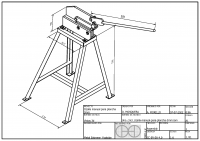

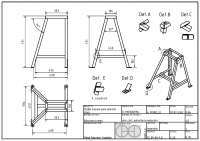

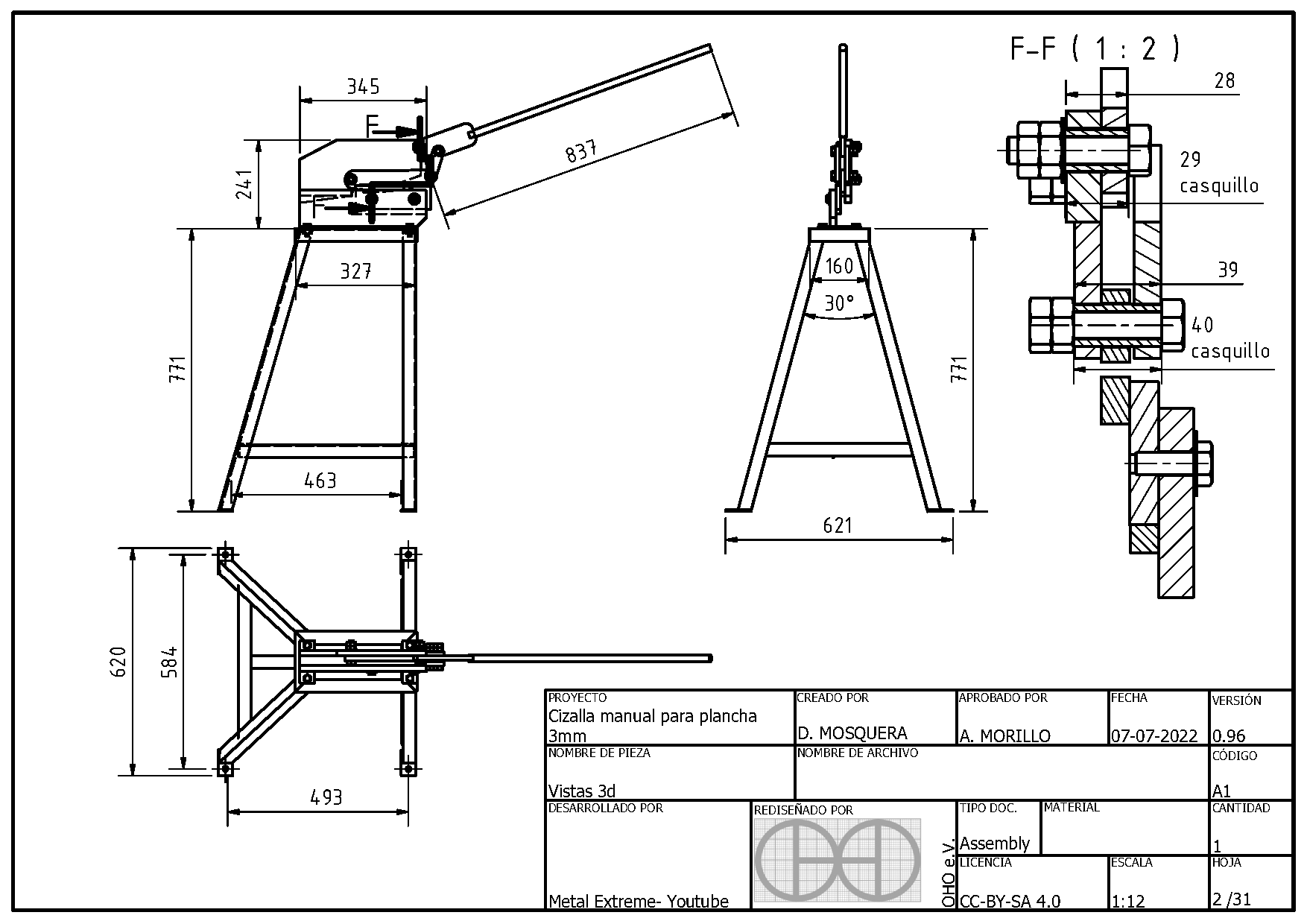

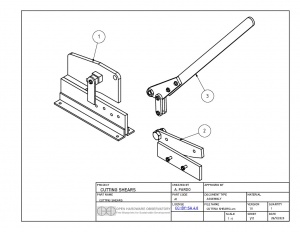

|cmptitle=PDF plans | |cmptitle=PDF plans | ||

|cmpimage=Oho cm3 002.png | |cmpimage=Oho cm3 002.png | ||

|cmpfile1=Oho cm3 cizalla-manual-para-plancha-3mm 0.96.pdf | |cmpfile1=Oho cm3 cizalla-manual-para-plancha-3mm 0.96.pdf | ||

}}{{ | }} | ||

{{ProjektComponent2 | |||

|cmptitle=CAD files | |cmptitle=CAD files | ||

|cmpimage=Oho cm3 render2.png | |cmpimage=Oho cm3 render2.png | ||

| Line 60: | Line 100: | ||

|cmpfile2=oho_cm3_DWG-files.zip | |cmpfile2=oho_cm3_DWG-files.zip | ||

|cmpfile3=oho_cm3_CAD-files2.zip | |cmpfile3=oho_cm3_CAD-files2.zip | ||

}} | |||

<div style="margin:20px"></div> | |||

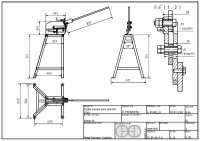

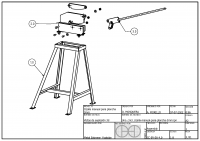

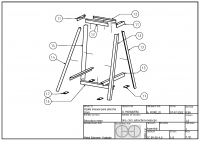

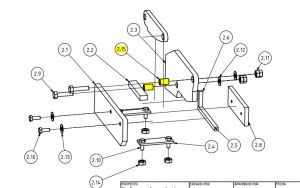

{{ProjektComponent2 | |||

|cmptitle=Assembly instructions | |||

<!-- |cmpimage= --> | |||

|cmpimg= | |||

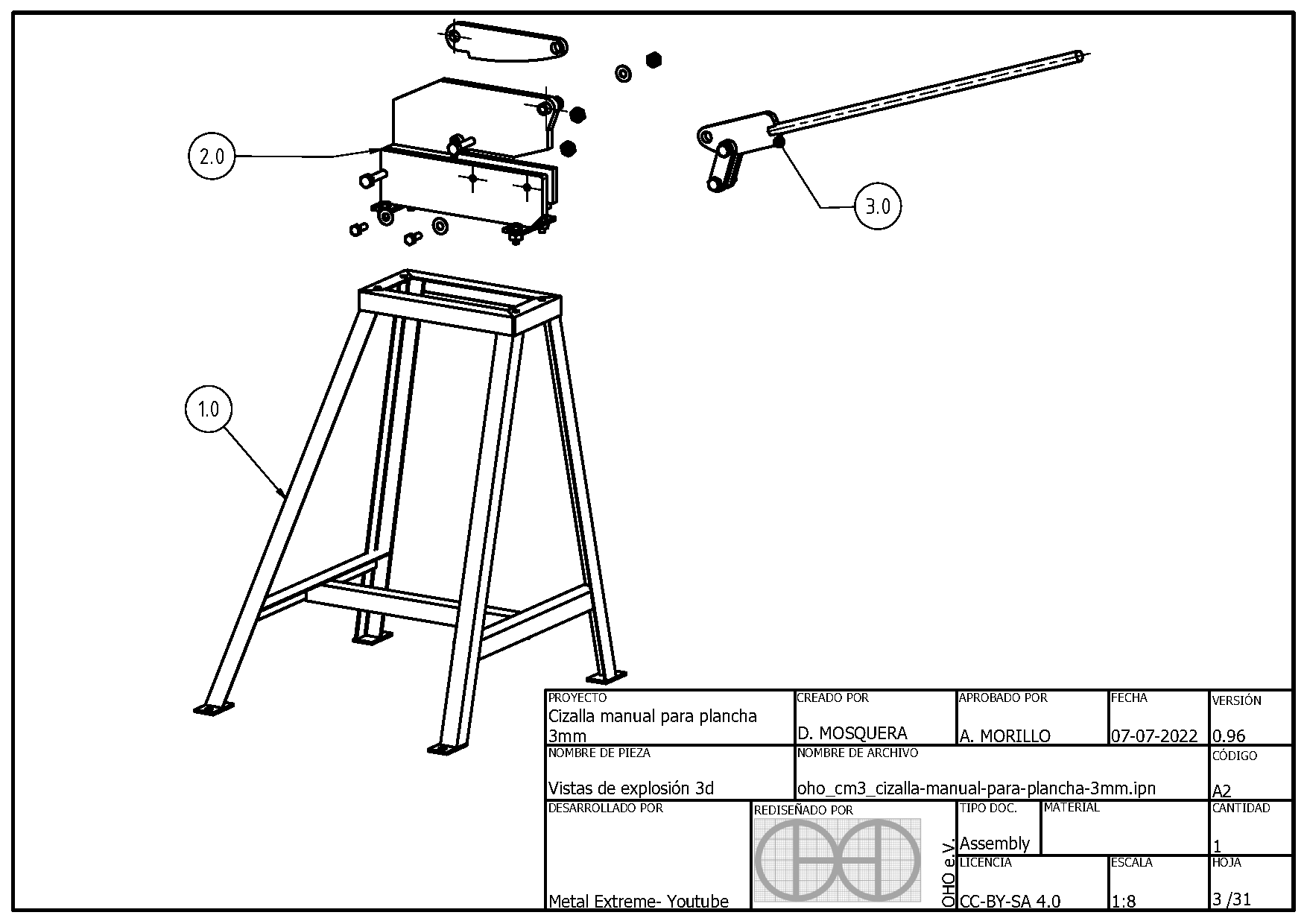

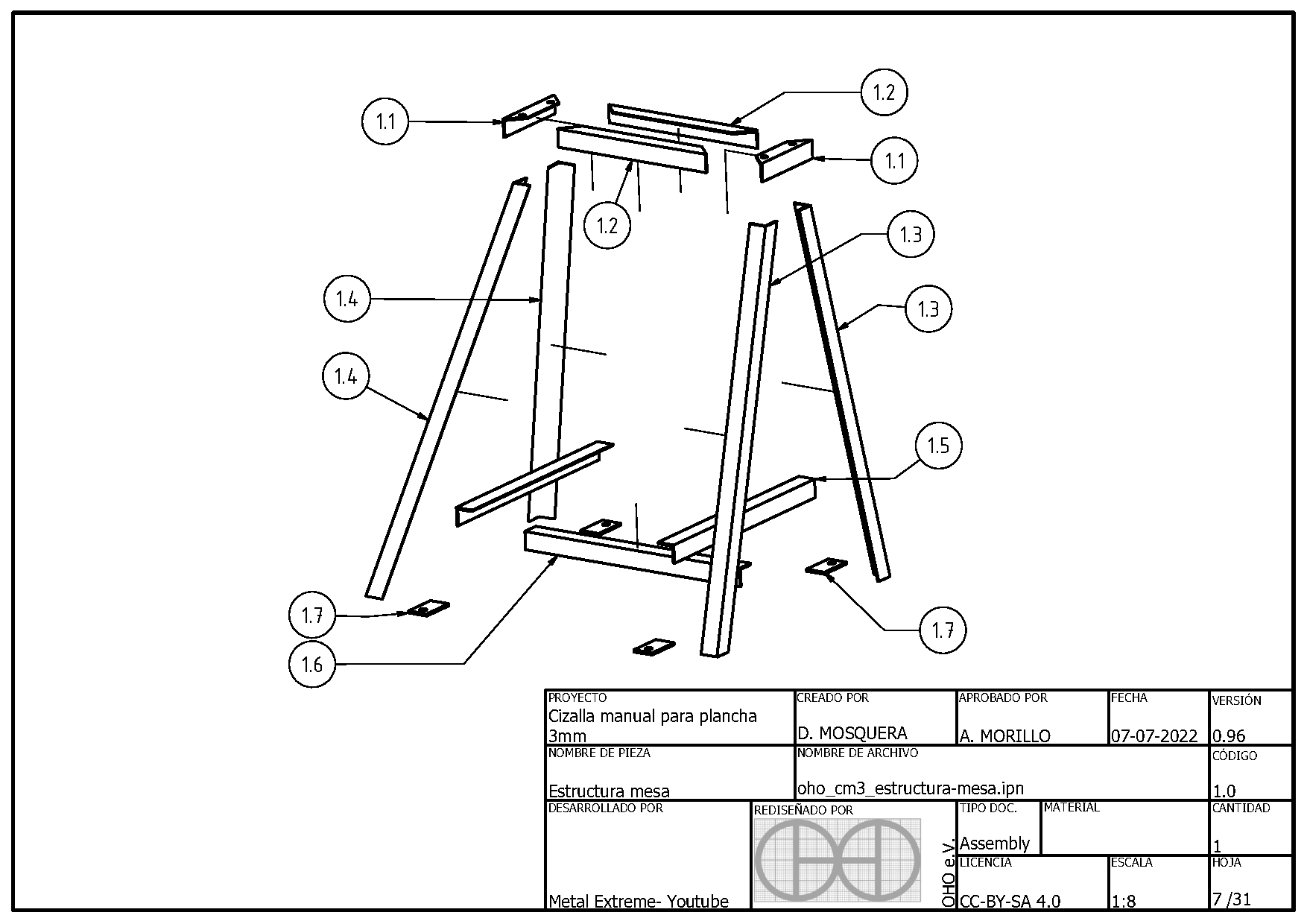

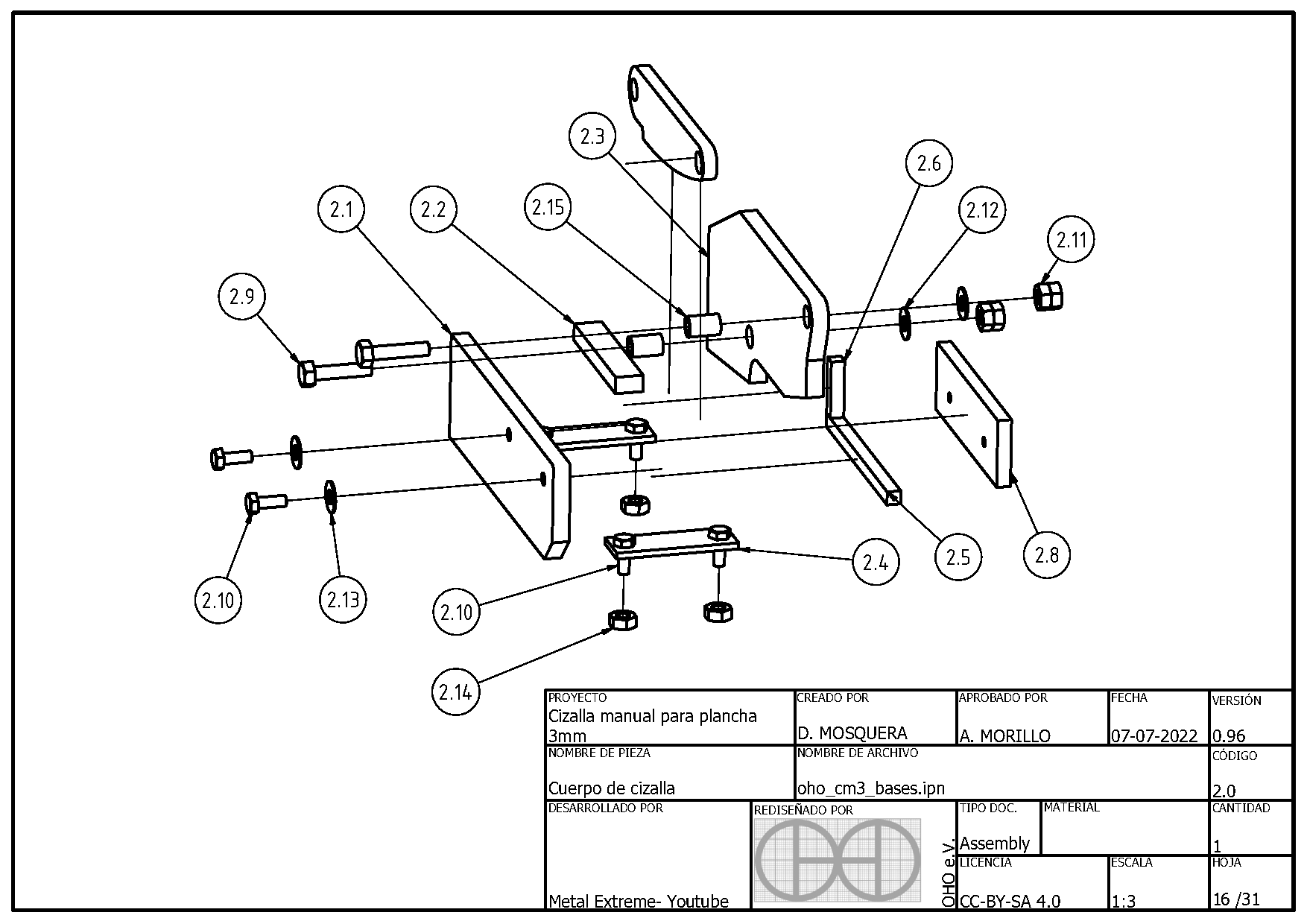

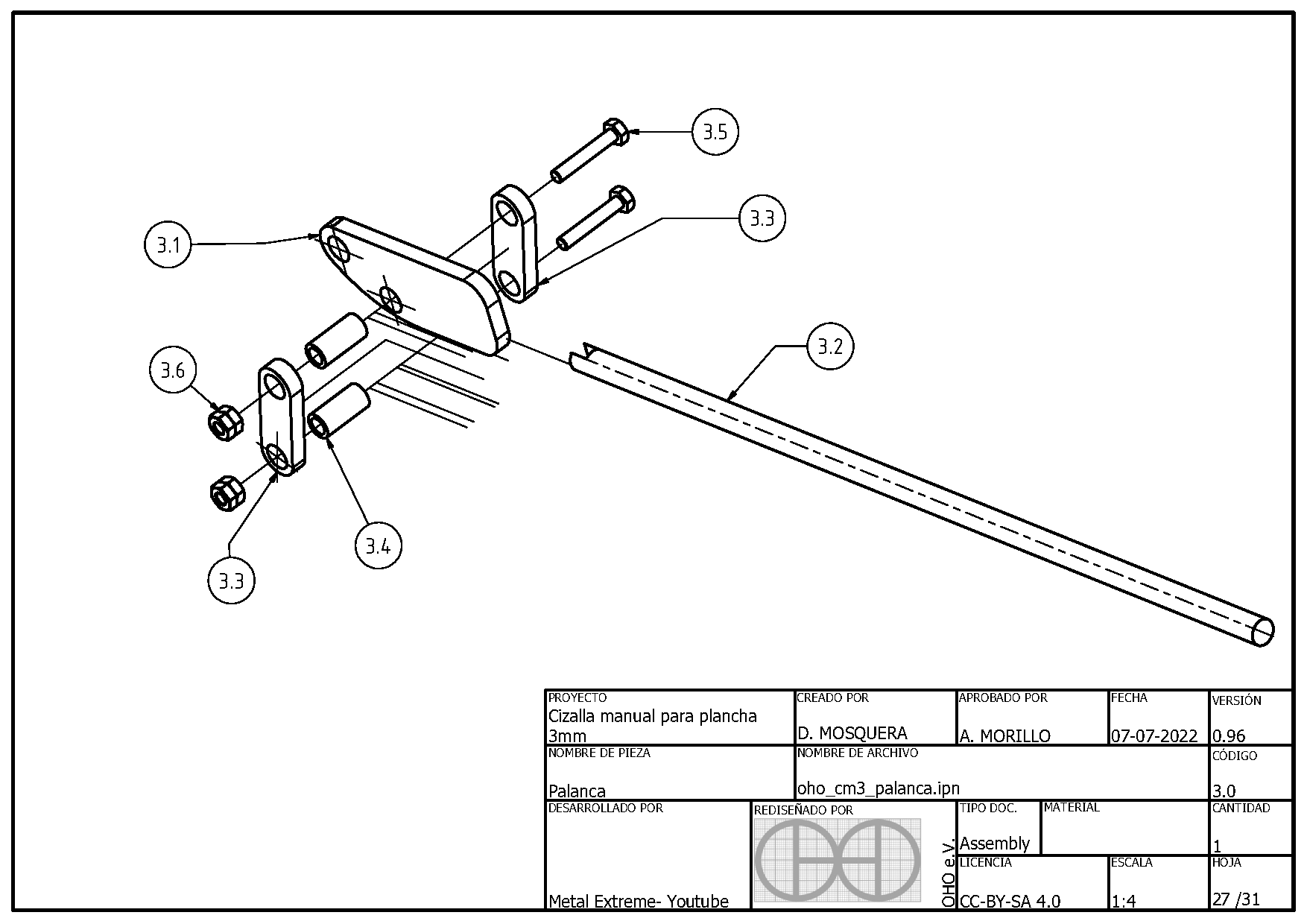

Here are some plans with the assembly sets and pieces, which can be detailed at [https://www.youtube.com/watch?v=l8SEEqtCDrc this link] | |||

<div class="mw-collapsible" id="mw-customcollapsible-div2" data-origID="mw-customcollapsible-div2"> | |||

<div style="text-align:left;"> | |||

<i class="mw-customtoggle-div2" style="color:#1b599a;">Zoom in</i> | |||

</div> | |||

<div class="res-img col-auto col-sm-auto col-md-auto col-lg-5 col-xl-5"> | |||

[[File:Oho_cm3_003.png]] | |||

<div style="margin:20px"></div> | |||

[[File:Oho_cm3_007.png]] | |||

<div style="margin:20px"></div> | |||

[[File:Oho_cm3_016.png]] | |||

<div style="margin:20px"></div> | |||

[[File:Oho_cm3_027.png]] | |||

</div> | |||

</div> | |||

<div class="mw-collapsible mw-collapsed" id="mw-customcollapsible-div2" data-origID="mw-customcollapsible-div2"> | |||

<div style="text-align:left;;"> | |||

<i class="mw-customtoggle-div2" style="color:#1b599a;">Zoom out</i> | |||

</div> | |||

<div class="res-img" style="width: 800px"> | |||

[[File:Oho_cm3_003.png]] | |||

<div style="margin:20px"></div> | |||

[[File:Oho_cm3_007.png]] | |||

<div style="margin:20px"></div> | |||

[[File:Oho_cm3_016.png]] | |||

<div style="margin:20px"></div> | |||

[[File:Oho_cm3_027.png]] | |||

</div> | |||

</div> | |||

}} | |||

<div style="margin:20px"></div> | |||

{{ProjektComponent2 | |||

|wtbl2=col-auto col-sm-auto col-md-auto col-lg-auto col-xl-auto | |||

|cmptitle=Project development | |||

|cmpimg= | |||

<!-- {{pdcontent1}} --> | |||

<p>Based on the DIN 2221 standard, among others, OHO has established a series of <i class="mw-customtoggle-div1" style="color:#1b599a;">stages</i> in which the satisfactory completion of this project was carried out</p> | |||

<!-- <p class="mw-customtoggle-div1" style="color:#1b599a;">Click to expand</p> --> | |||

<div class="mw-collapsible" id="mw-customcollapsible-div1" data-origID="mw-customcollapsible-div1" data-origID="mw-customcollapsible-div1"><!-- mw-collapsed --> | |||

<h4 style="margin-top:15px"><span class="mw-headline">Feasibility study</span></h4> | |||

<hr> | |||

<ul> | |||

<li> | |||

Materials, components | |||

<div class="row" style="width: 100%"> | |||

<div class="col-sm-6"> | |||

<p style="margin-top:0;"> | |||

Required materials & components can be sourced or replaced locally? <br> | |||

✓ Yes <br> | |||

All the materials can be located with some ease, in hardware stores, parts stores and/or junkyards | |||

</p> | |||

</div> | |||

<div class="col-sm-6" style="display:flex;align-items:flex-start; justify-content:flex-end;"> | |||

[[File:Oseg_cs_A1_CUTTING-SHEARS_001.jpg|300px|thumb|<small>'''Previous theoretical case, showing the exploded view'''</small>|link=https://en.oho.wiki/wiki/Cutting_shears]] | |||

</div> | |||

</div> | |||

</li> | |||

<li> | |||

Manufacturing processes | |||

<div class="row" style="width: 100%"> | |||

<div class="col-sm-6"> | |||

<p style="margin-top:0;"> | |||

Required manufacturing processes can be povided locally? <br> | |||

✓ Yes <br> | |||

In a small workshop, all the processes required for manufacturing can be achieved | |||

</p> | |||

</div> | |||

<div class="col-sm-6" style="display:flex;align-items:flex-start; justify-content:flex-end;"> | |||

[[File:oho_cm3_QrTWE0wVggk-1430.png|300px|thumb|<small>'''Example showing the processes involved'''</small>|link=https://www.youtube.com/watch?v=QrTWE0wVggk]] | |||

</div> | |||

</div> | |||

</li> | |||

<li> | |||

Specific training | |||

<div class="row" style="width: 100%"> | |||

<div class="col-sm-6"> | |||

<p style="margin-top:0;"> | |||

Is specific training for manufacturing necessary and can be provided? <br> | |||

✓ Yes <br> | |||

Especially when it comes to heat treatment for the blades | |||

</p> | |||

</div> | |||

<div class="col-sm-6" style="display:flex;align-items:flex-start; justify-content:flex-end;"> | |||

[[File:oho_cm3_Oz5MzN0Pc_M-0045.png|300px|thumb|<small>'''Cutting blades'''</small>|link=https://youtu.be/Oz5MzN0Pc_M?t=45]] | |||

</div> | |||

</div> | |||

</li> | |||

<li> | |||

Sustainability | |||

<div class="row" style="width: 100%"> | |||

<div class="col-sm-6"> | |||

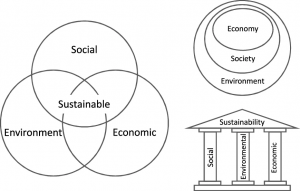

<p style="margin-top:0;"> | |||

Do all materials and processes meet the sustainability criteria? <br> | |||

✓ Yes <br> | |||

It is observed that both the materials used and the manufacturing processes are [https://en.wikipedia.org/wiki/Sustainability sustainable] from an economic, social and environmental point of view | |||

</p> | |||

</div> | |||

<div class="col-sm-6" style="display:flex;align-items:flex-start; justify-content:flex-end;"> | |||

[[File:oho_cm3_wikipedia-sustainability1.png|300px|thumb|<small>'''Sustainability concept'''</small>|link=https://en.wikipedia.org/wiki/Sustainability]] | |||

</div> | |||

</div> | |||

</li> | |||

</ul> | |||

<h4 style="margin-top:15px"><span class="mw-headline">Market analisis and requirements </span></h4> | |||

<hr> | |||

<ul> | |||

<li> | |||

Market analysis <br> | |||

Analysis of the current products on the market: | |||

<div class="row" style="width: 100%"> | |||

<div class="col-sm-12"> | |||

<p style="margin-bottom:0;"> | |||

[https://www.ebay.com/itm/181547305125 Sealey 3s/6r metal hand shear cutter cropper 13mm round 6mm cutting] | |||

</p> | |||

</div> | |||

</div> | |||

<div class="row" style="width: 100%"> | |||

<div class="col-sm-6"> | |||

<p style="margin-top:0;"> | |||

[[File:oho_cm3_YEqdlJHwmiE.jpg|300px|link=https://www.ebay.com/itm/181547305125]] | |||

<!-- https://www.youtube.com/watch?v=YEqdlJHwmiE --> | |||

</p> | |||

</div> | |||

<div class="col-sm-6" style="margin-top:0;"> | |||

<p style="margin-top:0;"> | |||

* Price [USD]: 237 <br> | |||

* Source: ebay <br> | |||

* Country: USA <br> | |||

* Machine condition: New <br> | |||

* Maximum sheet thickness [mm]: 6 <br> | |||

* Maximum round bar diameter [mm]: 13 <br> | |||

* Cutting length [mm]: 180 <br> | |||

* High hardness steel blade: Yes <br> | |||

* To screw on a metal bench: Yes | |||

</p> | |||

</div> | |||

</div> | |||

<div class="row" style="width: 100%"> | |||

<div class="col-sm-12"> | |||

<p style="margin-bottom:0;"> | |||

[https://www.ebay.com/itm/194499027198 5" Length Sheet Metal Plate Cutting Bench Hand Shear Machine Toolsmillar] | |||

</p> | |||

</div> | |||

</div> | |||

<div class="row" style="width: 100%"> | |||

<div class="col-sm-6"> | |||

<p style="margin-top:0;"> | |||

[[File:oho_cm3_C5nvVqsjo9Q.jpg|300px|link=https://www.ebay.com/itm/194499027198]] | |||

<!-- https://www.youtube.com/watch?v=C5nvVqsjo9Q --> | |||

</p> | |||

</div> | |||

<div class="col-sm-6" style="margin-top:0;"> | |||

<p style="margin-top:0;"> | |||

* Price [USD]: 243 <br> | |||

* Source: ebay <br> | |||

* Country: USA <br> | |||

* Machine condition: New <br> | |||

* Maximum sheet thickness [mm]: 4.08 <br> | |||

* Maximum round bar diameter [mm]: 11.11 <br> | |||

* Maximum thickness of plate or angle [mm]: 4.08 <br> | |||

* Cutting length [mm]: 127 <br> | |||

* High hardness steel blade: Yes <br> | |||

* To screw on a metal bench: Yes | |||

</p> | |||

</div> | |||

</div> | |||

<div class="row" style="width: 100%"> | |||

<div class="col-sm-12"> | |||

<p style="margin-bottom:0;"> | |||

[https://articulo.mercadolibre.com.ve/MLV-703546021-cizalla-cortadora-de-lamina-manual-somar-n4-tesoura-_JM Manual Sheet Cutter Somar N4 Tesoura] | |||

</p> | |||

</div> | |||

</div> | |||

<div class="row" style="width: 100%"> | |||

<div class="col-sm-6"> | |||

<p style="margin-top:0;"> | |||

[[File:oho_cm3_NYKOsfqPCC0.jpg|300px|link=https://articulo.mercadolibre.com.ve/MLV-703546021-cizalla-cortadora-de-lamina-manual-somar-n4-tesoura-_JM]] | |||

<!-- https://www.youtube.com/watch?v=NYKOsfqPCC0 --> | |||

</p> | |||

</div> | |||

<div class="col-sm-6" style="margin-top:0;"> | |||

<p style="margin-top:0;"> | |||

* Price [USD]: 100 <br> | |||

* Source: mercadolibre <br> | |||

* Country: Venezuela <br> | |||

* Machine condition: New <br> | |||

* Maximum sheet thickness [mm]: 4 <br> | |||

* Cutting length [mm]: 240 <br> | |||

* High hardness steel blade: Yes <br> | |||

* To screw on a metal bench: Yes | |||

</p> | |||

</div> | |||

</div> | |||

<div class="row" style="width: 100%"> | |||

<div class="col-sm-12"> | |||

<p style="margin-bottom:0;"> | |||

[https://articulo.mercadolibre.com.ve/MLV-709661898-5-inch-hoja-placa-metal-shear-construccion-tipo-montaje-_JM 5 Inch Sheet Metal Shear Plate Construction Type Mount] | |||

</p> | |||

</div> | |||

</div> | |||

<div class="row" style="width: 100%"> | |||

<div class="col-sm-6"> | |||

<p style="margin-top:0;"> | |||

[[File:oho_cm3_TLlFCBbGhaU.jpg|300px|link=https://articulo.mercadolibre.com.ve/MLV-709661898-5-inch-hoja-placa-metal-shear-construccion-tipo-montaje-_JM]] | |||

<!-- https://www.youtube.com/watch?v=TLlFCBbGhaU --> | |||

</p> | |||

</div> | |||

<div class="col-sm-6" style="margin-top:0;"> | |||

<p style="margin-top:0;"> | |||

* Price [USD]: 363 <br> | |||

* Source: mercadolibre <br> | |||

* Country: Venezuela <br> | |||

* Machine condition: New <br> | |||

* Cutting length [mm]: 160 <br> | |||

* High hardness steel blade: Yes <br> | |||

* To screw on a metal bench: Yes | |||

</p> | |||

</div> | |||

</div> | |||

</li> | |||

<li> | |||

Requirements definition <br> | |||

Definition of the main technical data (size, capacity, power...): | |||

<ul> | |||

<li>Maximum sheet thickness [mm]: 3</li> | |||

<li>Maximum round bar diameter [mm]: 13</li> | |||

<li>Maximum plate or angle thickness [mm]: 5</li> | |||

<li>Cutting length [mm]: 150-180</li> | |||

</ul> | |||

</li> | |||

<br> | |||

<li> | |||

Optimal functions and features: <br> | |||

Definition of necessary/optional functions and features | |||

<ul> | |||

<li>High hardness steel blade: Shear is required to have hardened steel blades</li> | |||

<li>To screw on a metal bench: It is preferred that the machine includes its own support structure</li> | |||

</ul> | |||

</li> | |||

</ul> | |||

<h4 style="margin-top:15px"><span class="mw-headline">Search & analisis DIY technologies</span></h4> | |||

<hr> | |||

<ul> | |||

<li> | |||

OHO Search engine | |||

<div class="row" style="width: 100%"> | |||

<div class="col-sm-6"> | |||

<p style="margin-top:0;"> | |||

Customization of the OHO search engine <br> | |||

A search for similar or related equipment was carried out in our repository, obtaining some equipment that can be used as a reference | |||

</p> | |||

</div> | |||

<div class="col-sm-6" style="margin-top:0;"> | |||

<p style="margin-top:0;"> | |||

[[File:oho_cm3_search1.jpg|300px|thumb|link=https://en.oho.wiki/wiki/Special:RunQuery/projectSearch?pfRunQueryFormName=projectSearch&ProjektSearch%5Bsearch%5D=shear&wpRunQuery=Search]] | |||

</p> | |||

</div> | |||

</div> | |||

</li> | |||

<li> | |||

Manual search <br> | |||

Searches were also performed within Google, Youtube, special websites etc., getting, among others, the following results: <br><br> | |||

<div class="row" style="width: 100%"> | |||

<div class="col-sm-6" style="margin-top:0;"> | |||

<p style="margin-top:0;"> | |||

* Title: Homemade shears for sheet cutting <br> | |||

* Views: 280000<br> | |||

* Likes: 4900<br> | |||

* Comments: 285 <br> | |||

* Maximum sheet thickness [mm]: 3 <br> | |||

* Maximum thickness of plate [mm]: 3 <br> | |||

* Cutting length [mm]: 205 <br> | |||

* High hardness steel blade: Yes <br> | |||

* To screw on a metal bench: Yes <br> | |||

This example will be used as the main reference machine | |||

</p> | |||

</div> | |||

<div class="col-sm-6" style="display:flex;align-items:flex-start; justify-content:flex-end;"> | |||

<p style="margin-top:0;"> | |||

[[File:oho_cm3_3l5sapINxAM.jpg|300px|thumb|link=https://www.youtube.com/watch?v=3l5sapINxAM]] | |||

</p> | |||

</div> | |||

</div> | |||

<div class="row" style="width: 100%"> | |||

<div class="col-sm-6" style="margin-top:0;"> | |||

<p style="margin-top:0;"> | |||

* Title: Leaf Spring HACK - Metal Cutter <br> | |||

* Views: 486000<br> | |||

* Likes: 5800<br> | |||

* Comments: 162 <br> | |||

* Maximum sheet thickness [mm]: 2.5 <br> | |||

* Maximum thickness of plate [mm]: 2.5 <br> | |||

* Cutting length [mm]: 200 <br> | |||

* High hardness steel blade: Yes <br> | |||

* To screw on a metal bench: Yes | |||

</p> | |||

</div> | |||

<div class="col-sm-6" style="display:flex;align-items:flex-start; justify-content:flex-end;"> | |||

<p style="margin-top:0;"> | |||

[[File:oho_cm3_ZLxexHEj-yU.jpg|300px|thumb|link=https://www.youtube.com/watch?v=ZLxexHEj-yU]] | |||

</p> | |||

</div> | |||

</div> | |||

<div class="row" style="width: 100%"> | |||

<div class="col-sm-6" style="margin-top:0;"> | |||

<p style="margin-top:0;"> | |||

* Title: Homemade metal shear <br> | |||

* Views: 331000<br> | |||

* Likes: 3200<br> | |||

* Comments: 123 <br> | |||

* Maximum sheet thickness [mm]: 3 <br> | |||

* Maximum thickness of plate [mm]: 3 <br> | |||

* Cutting length [mm]: 130 <br> | |||

* High hardness steel blade: Yes <br> | |||

* To screw on a metal bench: Yes | |||

</p> | |||

</div> | |||

<div class="col-sm-6" style="display:flex;align-items:flex-start; justify-content:flex-end;"> | |||

<p style="margin-top:0;"> | |||

[[File:oho_cm3_YEqdlJHwmiE.jpg|300px|thumb|link=https://www.youtube.com/watch?v=YEqdlJHwmiE]] | |||

</p> | |||

</div> | |||

</div> | |||

<div class="row" style="width: 100%"> | |||

<div class="col-sm-6" style="margin-top:0;"> | |||

<p style="margin-top:0;"> | |||

* Title: Manual Sheet Shear <br> | |||

* Views: 236000<br> | |||

* Likes: 4600<br> | |||

* Comments: 215 <br> | |||

* Maximum sheet thickness [mm]: 3.6 <br> | |||

* Cutting length [mm]: 200 <br> | |||

* High hardness steel blade: Yes <br> | |||

* To screw on a metal bench: Yes | |||

</p> | |||

</div> | |||

<div class="col-sm-6" style="display:flex;align-items:flex-start; justify-content:flex-end;"> | |||

<p style="margin-top:0;"> | |||

[[File:oho_cm3_QrTWE0wVggk.jpg|300px|thumb|link=https://www.youtube.com/watch?v=QrTWE0wVggk]] | |||

</p> | |||

</div> | |||

</div> | |||

</li> | |||

<li> | |||

Networking <br> | |||

This section refers to contacting partners, associated organizations and experts <br> | |||

Since the cases found on the internet provide enough information, it was not necessary to search for reference equipment in this way, it can be useful when working with unusual equipments | |||

</li> | |||

</ul> | |||

<h4 style="margin-top:15px"><span class="mw-headline">Development & documentation</span></h4> | |||

<hr> | |||

<ul> | |||

<li> | |||

Analisis of functions & structures | |||

<div class="row" style="width: 100%"> | |||

<div class="col-sm-6" style="margin-top:0;"> | |||

<p style="margin-top:0;"> | |||

From analyzing the operation and parts of the [https://www.youtube.com/watch?v=3l5sapINxAM main reference machine] and the rest of the examples obtained, a first list of components for the shear is generated | |||

</p> | |||

</div> | |||

<div class="col-sm-6" style="display:flex;align-items:flex-start; justify-content:flex-end;"> | |||

<p style="margin-top:0;"> | |||

[[File:oho_cm3_dt1.jpg|300px|thumb]] | |||

</p> | |||

</div> | |||

</div> | |||

<div class="row" style="width: 100%"> | |||

<div class="col-sm-6" style="margin-top:0;"> | |||

<p style="margin-top:0;"> | |||

During this process, some measurements of the parts and assemblies, essential for the design, are extracted | |||

</p> | |||

</div> | |||

<div class="col-sm-6" style="display:flex;align-items:flex-start; justify-content:flex-end;"> | |||

<p style="margin-top:0;"> | |||

[[File:oho_cm3_dt2.jpg|300px|thumb]] | |||

</p> | |||

</div> | |||

</div> | |||

</li> | |||

<li> | |||

Technical solutions | |||

<div class="row" style="width: 100%"> | |||

<div class="col-sm-6" style="margin-top:0;"> | |||

<p style="margin-top:0;"> | |||

The OHO development team also proceeds to design and determine the engineering problems that arise, in order to obtain a quality product that can be manufactured with Appropriate Technologies | |||

</p> | |||

</div> | |||

<div class="col-sm-6" style="display:flex;align-items:flex-start; justify-content:flex-end;"> | |||

<p style="margin-top:0;"> | |||

[[File:oho_cm3_dt3.jpg|300px|thumb]] | |||

</p> | |||

</div> | |||

</div> | |||

<div class="row" style="width: 100%"> | |||

<div class="col-sm-6" style="margin-top:0;"> | |||

<p style="margin-top:0;"> | |||

One of the solutions generated by the technical team was the inclusion of some bushings in the joints, this to ensure that these joints do not get stuck and enough tightening to support the loads | |||

</p> | |||

</div> | |||

<div class="col-sm-6" style="display:flex;align-items:flex-start; justify-content:flex-end;"> | |||

<p style="margin-top:0;"> | |||

[[File:oho_cm3_dt5.jpg|300px|thumb]] | |||

</p> | |||

</div> | |||

</div> | |||

</li> | |||

<li> | |||

Repo for Technical documentation | |||

<div class="row" style="width: 100%"> | |||

<div class="col-sm-6" style="margin-top:0;"> | |||

<p style="margin-top:0;"> | |||

There is an internal and self-managed Gitlab repository, where the preparation of plans, exploded views, the final parts list, details and annotations, among others, are controlled at a formal and technical level | |||

</p> | |||

</div> | |||

<div class="col-sm-6" style="display:flex;align-items:flex-start; justify-content:flex-end;"> | |||

<p style="margin-top:0;"> | |||

[[File:oho_cm3_gitlab1.jpg|300px|thumb]] | |||

</p> | |||

</div> | |||

</div> | |||

</li> | |||

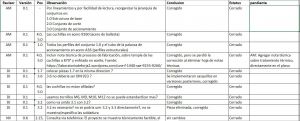

<li> | |||

Peer-Reviews | |||

<div class="row" style="width: 100%"> | |||

<div class="col-sm-6" style="margin-top:0;"> | |||

<p style="margin-top:0;"> | |||

Before continuing with manufacturing, a group of experts was convened to verify the plans and generate observations, in order to optimize the design and prevent errors during later stages | |||

</p> | |||

</div> | |||

<div class="col-sm-6" style="display:flex;align-items:flex-start; justify-content:flex-end;"> | |||

<p style="margin-top:0;"> | |||

[[File:oho_cm3_dt4.jpg|300px|thumb]] | |||

</p> | |||

</div> | |||

</div> | |||

</li> | |||

</ul> | |||

==== Manufacturing, tests and improvements ==== | |||

----- | |||

<!-- * Workshop [[File:Review.png|20px|link=https://en.oho.wiki/index.php?title=Talk:Manual_shearing_machine_for_3mm_plate&action=edit§ion=new&preloadtitle=Technical_development_5.1]] <br> Determination of the workshop for manufacturing: <br> Among the most important aspects to be fulfilled by the manufacturing workshop, we have: [[File:pdc_workshop3.jpg|300px|thumb]] --> | |||

<!-- * Workshop [ | |||

{{fullurl: | |||

{{TALKPAGENAME}}|action=edit§ion=1&showtitle=1&preloadtitle=Technical_development|class=linksPopups}} Comments] <br> Determination of the workshop for manufacturing: <br> Among the most important aspects to be fulfilled by the manufacturing workshop, we have: [[File:pdc_workshop3.jpg|300px|thumb]] --> | |||

<!-- * Workshop [[File:Review.png|20px|link= | |||

{{fullurl: | |||

{{TALKPAGENAME}}|action=edit§ion=1&showtitle=1&preloadtitle=Technical_development-Workshop|class=linksPopups}}|Comments]] <br> Determination of the workshop for manufacturing: <br> Among the most important aspects to be fulfilled by the manufacturing workshop, we have: [[File:pdc_workshop3.jpg|300px|thumb]] --> | |||

* Workshop <br> Determination of the workshop for manufacturing: <br> Among the most important aspects to be fulfilled by the manufacturing workshop, we have: [[File:pdc_workshop3.jpg|300px|thumb]] | |||

** It does not require industrial or specialized processes such as plastic processing, CNC machining, complex chemical processes, among others | |||

** It has basic tools for working with metal and wood at a non-industrial level | |||

** It has measuring instruments appropriate to the processes, such as: vernier, tape measure, thread counter, gauges, etc. | |||

** Includes painting equipment such as compressor and spray gun | |||

** It is a space large enough and ordered for manufacturing, assembly and painting operations | |||

** It has qualified personnel in basic and intermediate works with metal, wood, painting, among others | |||

** Some parts or processes that are not available may be purchased or ordered from more specialized stores and workshops | |||

* Purchase <br> Purchase of materials and components: <br> From the list of parts, the amounts of materials to be required from local suppliers were totaled [[File:oho_cm3_materials-list1.png|300px|thumb]] | |||

** Structural profiles | |||

** Fasteners | |||

** Special profiles | |||

** Metal plates | |||

** Consumables | |||

<div style="margin:130px"></div> | |||

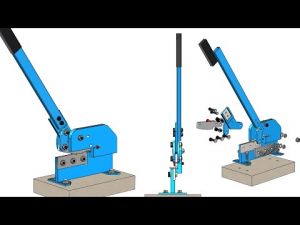

* Manufacturing of prototype <br> Fabrication according to specified quality standards: <br> The manufacturing process is oriented according to the order of the assemblies in the parts list and their assembly logic, this is shown in the various stages of the manufacturing video: [[File:oho_cm3_fab1.jpg|300px|thumb|link=https://www.youtube.com/watch?v=Oz5MzN0Pc_M]] | |||

** [https://www.youtube.com/watch?v=Oz5MzN0Pc_M&t=6s Introduction] | |||

** [https://www.youtube.com/watch?v=Oz5MzN0Pc_M&t=32s Cutting Blades] | |||

** [https://www.youtube.com/watch?v=Oz5MzN0Pc_M&t=82s Support table] | |||

** [https://www.youtube.com/watch?v=Oz5MzN0Pc_M&t=110s Equipment body] | |||

** [https://www.youtube.com/watch?v=Oz5MzN0Pc_M&t=284s Painting and assembly] | |||

<div style="margin:80px"></div> | |||

* Tests and improvement <br> Module tests, system tests, improvement of components: <br> Some [https://www.youtube.com/watch?v=Oz5MzN0Pc_M&t=338s tests] were carried out on the equipment, to verify the correct adjustment of the parts and the efficiency in its operation. [[File:oho_cm3_wtest1.jpg|300px|thumb|link=https://www.youtube.com/watch?v=Oz5MzN0Pc_M&t=338s]] | |||

** Lateral slack: Apply moderate force on the lever, from left to right and vice versa, alternately. The plates do not tilt | |||

** Example of real use: Making cuts of the samples of plate and sheet | |||

** Visual detail of the cut: Straight shape of the cut, Straight edge, no burrs | |||

<div style="margin:110px"></div> | |||

* Updates of technical documentation <br> Updates of plans, parts lists, assembly instructions: | |||

** The main plates (2.1 to 2.3) were manufactured in a thickness of 12mm, which is sufficient, instead of the 16mm initially proposed | |||

** Modification in the length of the bushings, according to the new plate thicknesses | |||

** Pieces 2.5 and 2.6, manufactured in 1/2" square bar, available in the workshop | |||

** Mobile blade (piece 2.7), with dimensions adjusted according to the leaf spring piece achieved, recovered material | |||

:Plans are expected to be updated with these changes, in order to have accurate information regarding the equipment manufactured | |||

==== Certification DIN Spec 3105 ==== | |||

----- | |||

* Formal audit <br> Verification of the completeness of the documents: [[File:oho_cm3_gitlab2.jpg|300px|thumb]] | |||

** Parts list | |||

** Drawings of all parts and assemblies | |||

** Assembly instructions | |||

** Optional documents, technical notes | |||

: In the image, it can be seen that this verification is complete, except for the previous corrections, which refer to the final update of the blueprints | |||

<div style="margin:20px"></div> | |||

* Assignment of reviewers <br> Search and assignment of peer-reviewers with sufficient expertise: | |||

**[[User:Xtech2020_review|Xtech2020_review]] | |||

** [[User:Thehunter|Thehunter]] | |||

* Peer-reviews <br> Realization of the peer reviews, technical clarification, improvements: In process | |||

* Certificate <br> Issue of the certificate: In process | |||

<!-- ==== 7. Promotion, formation ==== | |||

----- | |||

* PDF documentation <br> Creation of PDF documentation, training materials etc.: | |||

* Video production <br> Production of blueprint videos, fabricaction videos etc.: | |||

* Publishing <br> Publishing on own website, Wikipedia, social media: | |||

* Use in projects <br> Use in development cooperation projects, cooperation with partners: | |||

--> | |||

</div> | |||

}} | }} | ||

|Materials= | |Materials= | ||

| Line 66: | Line 613: | ||

|matquantity=1 | |matquantity=1 | ||

|matdesc=3D views | |matdesc=3D views | ||

|matpdffile=oho_cm3_A1_Vistas 3D.pdf | |matpdffile=oho_cm3_A1_Vistas 3D.pdf | ||

}} | }} | ||

| Line 74: | Line 619: | ||

|matquantity=1 | |matquantity=1 | ||

|matdesc=Exloded 3D views | |matdesc=Exloded 3D views | ||

|matpdffile=oho_cm3_A2_Vistas de explosión 3d.pdf | |matpdffile=oho_cm3_A2_Vistas de explosión 3d.pdf | ||

}} | }} | ||

{{ProjektMaterials | {{ProjektMaterials | ||

|matpartnumber=B | |matpartnumber=B | ||

|matdesc=Parts list | |matdesc=Parts list | ||

|matpdffile=oho_cm3_B_Parts list.pdf | |matpdffile=oho_cm3_B_Parts list.pdf | ||

}} | }} | ||

| Line 90: | Line 630: | ||

|matquantity=1 | |matquantity=1 | ||

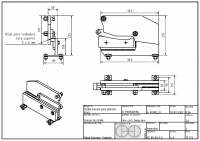

|matdesc=Table structure | |matdesc=Table structure | ||

|matpdffile=oho_cm3_1.0_Estructura mesa.pdf | |matpdffile=oho_cm3_1.0_Estructura mesa.pdf | ||

}} | }} | ||

| Line 154: | Line 692: | ||

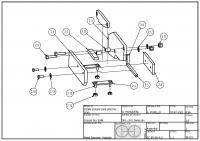

|matquantity=1 | |matquantity=1 | ||

|matdesc=Shear body | |matdesc=Shear body | ||

|matpdffile=oho_cm3_2.0_Cuerpo de cizalla.pdf | |matpdffile=oho_cm3_2.0_Cuerpo de cizalla.pdf | ||

}} | }} | ||

| Line 228: | Line 764: | ||

|matparttype=standard | |matparttype=standard | ||

|matspec=Hex bolt 1/2*2 1/4" NC | |matspec=Hex bolt 1/2*2 1/4" NC | ||

}} | }} | ||

{{ProjektMaterials | {{ProjektMaterials | ||

| Line 236: | Line 771: | ||

|matparttype=standard | |matparttype=standard | ||

|matspec=Hexagonal screw 3/8*1 1/8" NC, optional l 1" hexagonal screw | |matspec=Hexagonal screw 3/8*1 1/8" NC, optional l 1" hexagonal screw | ||

}} | }} | ||

{{ProjektMaterials | {{ProjektMaterials | ||

| Line 244: | Line 778: | ||

|matparttype=standard | |matparttype=standard | ||

|matspec=Hex nut 1/2" NC | |matspec=Hex nut 1/2" NC | ||

}} | }} | ||

{{ProjektMaterials | {{ProjektMaterials | ||

| Line 252: | Line 785: | ||

|matparttype=standard | |matparttype=standard | ||

|matspec=Flat washer for 1/2" NC | |matspec=Flat washer for 1/2" NC | ||

}} | }} | ||

{{ProjektMaterials | {{ProjektMaterials | ||

| Line 260: | Line 792: | ||

|matparttype=standard | |matparttype=standard | ||

|matspec=Flat washer for 3/8" NC | |matspec=Flat washer for 3/8" NC | ||

}} | }} | ||

{{ProjektMaterials | {{ProjektMaterials | ||

| Line 268: | Line 799: | ||

|matparttype=standard | |matparttype=standard | ||

|matspec=Hex nut 3/8" NC | |matspec=Hex nut 3/8" NC | ||

}} | }} | ||

{{ProjektMaterials | {{ProjektMaterials | ||

| Line 282: | Line 812: | ||

|matquantity=1 | |matquantity=1 | ||

|matdesc=Lever | |matdesc=Lever | ||

|matpdffile=oho_cm3_3.0_Palanca.pdf | |matpdffile=oho_cm3_3.0_Palanca.pdf | ||

}} | }} | ||

| Line 324: | Line 852: | ||

|matparttype=standard | |matparttype=standard | ||

|matspec=Hex bolt 1/2*2 1/2" NC | |matspec=Hex bolt 1/2*2 1/2" NC | ||

}} | }} | ||

{{ProjektMaterials | {{ProjektMaterials | ||

| Line 332: | Line 859: | ||

|matparttype=standard | |matparttype=standard | ||

|matspec=Hex nut 1/2" NC | |matspec=Hex nut 1/2" NC | ||

}} | }} | ||

|certificate_requested=No | |certificate_requested=No | ||

|certificate_status=in process | |||

|reviewer1=Xtech2020 review | |||

|reviewer2=Thehunter | |||

}} | }} | ||

Latest revision as of 00:10, 21 April 2023

Project data

|

Category: Shears URL (first publication): https://www.youtube.com/watch?v=Oz5MzN0Pc_M Keywords: cutting, shear, diy, metal, machine, workshop, open source, spring steel, hardening License: CC BY-NC-SA 4.0 Organization: OHO Project status: Active Certification status: In process

Maturity of the project: prototype

Contains PDF-drawings: Yes CAD files are editable: Yes Assembly instructions are published: Yes Bill of materials is published: Yes

yes yes

|

Project details

Description

The cutting shears boast a robust design made possible through thorough research of online videos and incorporation of repurposed car leaf springs that underwent a heat treatment. The end result is a durable yet environmentally conscious tool capable of handling challenging metal cutting tasks with ease.

Technical data

Below are some features of the manufactured shears:

- Maximum sheet thickness: 3mm

- Maximum round bar diameter: 13mm

- Maximum plate or angle thickness: 5mm

- Cutting length: 180mm

- Dimensions: Length: 0.6m x Width: 0.6m x Height: 1m

- Weight: Approximately 23 kg

- Blade Type: Hardened 9260 steel

- Drive: Manual lever

Technical documentation

Assembly instructions

Here are some plans with the assembly sets and pieces, which can be detailed at this link

Project development

Based on the DIN 2221 standard, among others, OHO has established a series of stages in which the satisfactory completion of this project was carried out

Feasibility study

- Materials, components

- Manufacturing processes

- Specific training

-

Sustainability

Do all materials and processes meet the sustainability criteria?

✓ Yes

It is observed that both the materials used and the manufacturing processes are sustainable from an economic, social and environmental point of view

Market analisis and requirements

-

Market analysis

Analysis of the current products on the market:* Price [USD]: 237

* Source: ebay

* Country: USA

* Machine condition: New

* Maximum sheet thickness [mm]: 6

* Maximum round bar diameter [mm]: 13

* Cutting length [mm]: 180

* High hardness steel blade: Yes

* To screw on a metal bench: Yes* Price [USD]: 243

* Source: ebay

* Country: USA

* Machine condition: New

* Maximum sheet thickness [mm]: 4.08

* Maximum round bar diameter [mm]: 11.11

* Maximum thickness of plate or angle [mm]: 4.08

* Cutting length [mm]: 127

* High hardness steel blade: Yes

* To screw on a metal bench: Yes* Price [USD]: 100

* Source: mercadolibre

* Country: Venezuela

* Machine condition: New

* Maximum sheet thickness [mm]: 4

* Cutting length [mm]: 240

* High hardness steel blade: Yes

* To screw on a metal bench: Yes -

Requirements definition

Definition of the main technical data (size, capacity, power...):- Maximum sheet thickness [mm]: 3

- Maximum round bar diameter [mm]: 13

- Maximum plate or angle thickness [mm]: 5

- Cutting length [mm]: 150-180

-

Optimal functions and features:

Definition of necessary/optional functions and features- High hardness steel blade: Shear is required to have hardened steel blades

- To screw on a metal bench: It is preferred that the machine includes its own support structure

Search & analisis DIY technologies

- OHO Search engine

-

Manual search

Searches were also performed within Google, Youtube, special websites etc., getting, among others, the following results:

* Title: Homemade shears for sheet cutting

* Views: 280000

* Likes: 4900

* Comments: 285

* Maximum sheet thickness [mm]: 3

* Maximum thickness of plate [mm]: 3

* Cutting length [mm]: 205

* High hardness steel blade: Yes

* To screw on a metal bench: Yes

This example will be used as the main reference machine* Title: Leaf Spring HACK - Metal Cutter

* Views: 486000

* Likes: 5800

* Comments: 162

* Maximum sheet thickness [mm]: 2.5

* Maximum thickness of plate [mm]: 2.5

* Cutting length [mm]: 200

* High hardness steel blade: Yes

* To screw on a metal bench: Yes* Title: Homemade metal shear

* Views: 331000

* Likes: 3200

* Comments: 123

* Maximum sheet thickness [mm]: 3

* Maximum thickness of plate [mm]: 3

* Cutting length [mm]: 130

* High hardness steel blade: Yes

* To screw on a metal bench: Yes -

Networking

This section refers to contacting partners, associated organizations and experts

Since the cases found on the internet provide enough information, it was not necessary to search for reference equipment in this way, it can be useful when working with unusual equipments

Development & documentation

-

Analisis of functions & structures

From analyzing the operation and parts of the main reference machine and the rest of the examples obtained, a first list of components for the shear is generated

-

Technical solutions

The OHO development team also proceeds to design and determine the engineering problems that arise, in order to obtain a quality product that can be manufactured with Appropriate Technologies

- Repo for Technical documentation

- Peer-Reviews

Manufacturing, tests and improvements

- Workshop

Determination of the workshop for manufacturing:

Among the most important aspects to be fulfilled by the manufacturing workshop, we have:- It does not require industrial or specialized processes such as plastic processing, CNC machining, complex chemical processes, among others

- It has basic tools for working with metal and wood at a non-industrial level

- It has measuring instruments appropriate to the processes, such as: vernier, tape measure, thread counter, gauges, etc.

- Includes painting equipment such as compressor and spray gun

- It is a space large enough and ordered for manufacturing, assembly and painting operations

- It has qualified personnel in basic and intermediate works with metal, wood, painting, among others

- Some parts or processes that are not available may be purchased or ordered from more specialized stores and workshops

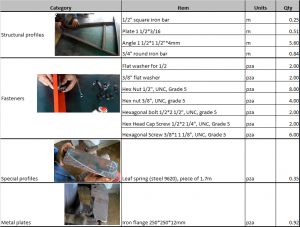

- Purchase

Purchase of materials and components:

From the list of parts, the amounts of materials to be required from local suppliers were totaled- Structural profiles

- Fasteners

- Special profiles

- Metal plates

- Consumables

- Manufacturing of prototype

Fabrication according to specified quality standards:

The manufacturing process is oriented according to the order of the assemblies in the parts list and their assembly logic, this is shown in the various stages of the manufacturing video:

- Tests and improvement

Module tests, system tests, improvement of components:

Some tests were carried out on the equipment, to verify the correct adjustment of the parts and the efficiency in its operation.- Lateral slack: Apply moderate force on the lever, from left to right and vice versa, alternately. The plates do not tilt

- Example of real use: Making cuts of the samples of plate and sheet

- Visual detail of the cut: Straight shape of the cut, Straight edge, no burrs

- Updates of technical documentation

Updates of plans, parts lists, assembly instructions:- The main plates (2.1 to 2.3) were manufactured in a thickness of 12mm, which is sufficient, instead of the 16mm initially proposed

- Modification in the length of the bushings, according to the new plate thicknesses

- Pieces 2.5 and 2.6, manufactured in 1/2" square bar, available in the workshop

- Mobile blade (piece 2.7), with dimensions adjusted according to the leaf spring piece achieved, recovered material

- Plans are expected to be updated with these changes, in order to have accurate information regarding the equipment manufactured

Certification DIN Spec 3105

- Formal audit

Verification of the completeness of the documents:- Parts list

- Drawings of all parts and assemblies

- Assembly instructions

- Optional documents, technical notes

- In the image, it can be seen that this verification is complete, except for the previous corrections, which refer to the final update of the blueprints

- Assignment of reviewers

Search and assignment of peer-reviewers with sufficient expertise: - Peer-reviews

Realization of the peer reviews, technical clarification, improvements: In process - Certificate

Issue of the certificate: In process

+ General Reviews

Reviews

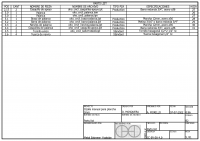

| Pos. | Qty. | Part Name | Part code | Part Type | Specifications | Review Status | Show All Comments | |

|---|---|---|---|---|---|---|---|---|

| A1 | 1 | 3D views | ||||||

| A2 | 1 | Exloded 3D views | ||||||

| B | Parts list | |||||||

| 1.0 | 1 | Table structure | ||||||

| 1.1 | 2 | Table angle | Production | Angle 1 1/2*1 1/2"*4mm, A36 steel | ||||

| 1.2 | 2 | Table side angle | Production | Angle 1 1/2*1 1/2"*4mm, A36 steel | ||||

| 1.3 | 2 | Table front angle | Production | Angle 1 1/2*1 1/2"*4mm, steel A36 | ||||

| 1.4 | 2 | Table back leg angle | Production | Angle 1 1/2*1 1/2"*4mm, steel A36 | ||||

| 1.5 | 2 | Table reinforcement angle | Production | Angle 1 1/2*1 1/2"*4mm, steel A36 | ||||

| 1.6 | 1 | Angle2 table reinforcement | Production | Angle 1 1/2*1 1/2"*4mm, steel A36 | ||||

| 1.7 | 4 | Anchor plate | Production | Plate 1 1/2*3/16", A36 steel | ||||

| 2.0 | 1 | Shear body | ||||||

| 2.1 | 1 | Lower base plate | Production | Plate 16mm, steel A36 | ||||

| 2.2 | 1 | Support center b | Production | Plate 16mm, steel A36 | ||||

| 2.3 | 1 | Upper base plate | Production | Plate 16mm, steel A36 | ||||

| 2.4 | 2 | Support plate | Production | Flat bar 1 1/2*3/16", steel A36 | ||||

| 2.5 | 1 | Blade support1 | Production | Square bar 1/2", steel A36 | ||||

| 2.6 | 1 | Blade support2 | Production | Square bar 1/2", steel A36 | ||||

| 2.7 | 1 | Mobile blade | Production | Leaf spring 10mm, steel 9260, optional 13mm | ||||

| 2.8 | 1 | Fixed blade | Production | Leaf spring 10mm, steel 9260, optional 13mm | ||||

| 2.9 | 2 | Screw for pivot | Standard | Hex bolt 1/2*2 1/4" NC | ||||

| 2.10 | 6 | Fixed blade screw | Standard | Hexagonal screw 3/8*1 1/8" NC, optional l 1" hexagonal screw | ||||

| 2.11 | 4 | Pivot nut | Standard | Hex nut 1/2" NC | ||||

| 2.12 | 2 | Washer2 | Standard | Flat washer for 1/2" NC | ||||

| 2.13 | 2 | Washer | Standard | Flat washer for 3/8" NC | ||||

| 2.14 | 4 | Support nut | Standard | Hex nut 3/8" NC | ||||

| 2.15 | 2 | Support bushing | Production | Round bar 3/4", A36 steel | ||||

| 3.0 | 1 | Lever | ||||||

| 3.1 | 1 | Lever arm | Production | Plate 12mm, A36 steel | ||||

| 3.2 | 1 | Lever bar | Production | Plate 3/16" or 3/4" round bar | ||||

| 3.3 | 2 | Lever arm | Production | Plate 12mm, A36 steel | ||||

| 3.4 | 2 | Lever bushing | Production | 3/4" round bar, A36 steel | ||||

| 3.5 | 2 | Union screw | Standard | Hex bolt 1/2*2 1/2" NC | ||||

| 3.6 | 4 | Rib nut | Standard | Hex nut 1/2" NC | ||||