Difference between revisions of "Manual shearing machine for 3mm plate"

Inddigital (talk | contribs) ((by SublimeText.Mediawiker)) |

|||

| Line 32: | Line 32: | ||

|firstin=https://www.youtube.com/watch?v=Oz5MzN0Pc_M | |firstin=https://www.youtube.com/watch?v=Oz5MzN0Pc_M | ||

|trans_status=WT | |trans_status=WT | ||

|desc= | |desc=<!-- <p>Based on the DIN 2221 standard, among others, OHO has established a series of stages in which the satisfactory completion of this project was carried out</p> --> | ||

<!-- <p>Based on the DIN 2221 standard, among others, OHO has established a series of stages in which the satisfactory completion of this project was carried out</p> --> | |||

__TOC__ | __TOC__ | ||

|licence=CCBYNCSA40 | |licence=CCBYNCSA40 | ||

| Line 51: | Line 50: | ||

|versioning_system=yes | |versioning_system=yes | ||

|contains_pdf_drawings=yes | |contains_pdf_drawings=yes | ||

|technology_readyness_level= | |technology_readyness_level=6 | ||

|TechDoc={{ProjektComponent | |TechDoc={{ProjektComponent | ||

|cmptitle=PDF plans | |cmptitle=PDF plans | ||

| Line 62: | Line 61: | ||

|cmpfile2=oho_cm3_DWG-files.zip | |cmpfile2=oho_cm3_DWG-files.zip | ||

|cmpfile3=oho_cm3_CAD-files2.zip | |cmpfile3=oho_cm3_CAD-files2.zip | ||

}} | }}{{ProjektComponent | ||

{{ProjektComponent | |||

|cmptitle=Project development | |cmptitle=Project development | ||

|cmpimg= | |cmpimg=<p>Based on the DIN 2221 standard, among others, OHO has established a series of <i class="mw-customtoggle-div1" style="color:#1b599a;">stages</i> in which the satisfactory completion of this project was carried out</p> | ||

<p>Based on the DIN 2221 standard, among others, OHO has established a series of <i class="mw-customtoggle-div1" style="color:#1b599a;">stages</i> in which the satisfactory completion of this project was carried out</p> | |||

<!-- <p class="mw-customtoggle-div1" style="color:#1b599a;">Click to expand</p> --> | <!-- <p class="mw-customtoggle-div1" style="color:#1b599a;">Click to expand</p> --> | ||

<div class="mw-collapsible" id="mw-customcollapsible-div1" data-origID="mw-customcollapsible-div1"><!-- mw-collapsed --> | <div class="mw-collapsible" id="mw-customcollapsible-div1" data-origID="mw-customcollapsible-div1" data-origID="mw-customcollapsible-div1"><!-- mw-collapsed --> | ||

<h4 style="margin-top:15px"><span class="mw-headline">1. Feasibility study</span></h4> | <h4 style="margin-top:15px"><span class="mw-headline">1. Feasibility study</span></h4> | ||

<hr> | <hr> | ||

| Line 528: | Line 525: | ||

</div> | </div> | ||

}} | }} | ||

|Materials={{ProjektMaterials | |||

|Materials= | |||

{{ProjektMaterials | |||

|matpartnumber=A1 | |matpartnumber=A1 | ||

|matquantity=1 | |matquantity=1 | ||

|matdesc=3D views | |matdesc=3D views | ||

|matpdffile=oho_cm3_A1_Vistas 3D.pdf | |matpdffile=oho_cm3_A1_Vistas 3D.pdf | ||

}} | }}{{ProjektMaterials | ||

{{ProjektMaterials | |||

|matpartnumber=A2 | |matpartnumber=A2 | ||

|matquantity=1 | |matquantity=1 | ||

|matdesc=Exloded 3D views | |matdesc=Exloded 3D views | ||

|matpdffile=oho_cm3_A2_Vistas de explosión 3d.pdf | |matpdffile=oho_cm3_A2_Vistas de explosión 3d.pdf | ||

}} | }}{{ProjektMaterials | ||

{{ProjektMaterials | |||

|matpartnumber=B | |matpartnumber=B | ||

|matdesc=Parts list | |matdesc=Parts list | ||

|matpdffile=oho_cm3_B_Parts list.pdf | |matpdffile=oho_cm3_B_Parts list.pdf | ||

}} | }}{{ProjektMaterials | ||

{{ProjektMaterials | |||

|matpartnumber=1.0 | |matpartnumber=1.0 | ||

|matquantity=1 | |matquantity=1 | ||

|matdesc=Table structure | |matdesc=Table structure | ||

|matpdffile=oho_cm3_1.0_Estructura mesa.pdf | |matpdffile=oho_cm3_1.0_Estructura mesa.pdf | ||

}} | }}{{ProjektMaterials | ||

{{ProjektMaterials | |||

|matpartnumber=1.1 | |matpartnumber=1.1 | ||

|matquantity=2 | |matquantity=2 | ||

| Line 569: | Line 551: | ||

|matspec=Angle 1 1/2*1 1/2"*4mm, A36 steel | |matspec=Angle 1 1/2*1 1/2"*4mm, A36 steel | ||

|matpdffile=oho_cm3_1.1_Angulo de mesa.pdf | |matpdffile=oho_cm3_1.1_Angulo de mesa.pdf | ||

}} | }}{{ProjektMaterials | ||

{{ProjektMaterials | |||

|matpartnumber=1.2 | |matpartnumber=1.2 | ||

|matquantity=2 | |matquantity=2 | ||

| Line 577: | Line 558: | ||

|matspec=Angle 1 1/2*1 1/2"*4mm, A36 steel | |matspec=Angle 1 1/2*1 1/2"*4mm, A36 steel | ||

|matpdffile=oho_cm3_1.2_Angulo lateral mesa.pdf | |matpdffile=oho_cm3_1.2_Angulo lateral mesa.pdf | ||

}} | }}{{ProjektMaterials | ||

{{ProjektMaterials | |||

|matpartnumber=1.3 | |matpartnumber=1.3 | ||

|matquantity=2 | |matquantity=2 | ||

| Line 585: | Line 565: | ||

|matspec=Angle 1 1/2*1 1/2"*4mm, steel A36 | |matspec=Angle 1 1/2*1 1/2"*4mm, steel A36 | ||

|matpdffile=oho_cm3_1.3_Angulo delante mesa.pdf | |matpdffile=oho_cm3_1.3_Angulo delante mesa.pdf | ||

}} | }}{{ProjektMaterials | ||

{{ProjektMaterials | |||

|matpartnumber=1.4 | |matpartnumber=1.4 | ||

|matquantity=2 | |matquantity=2 | ||

| Line 593: | Line 572: | ||

|matspec=Angle 1 1/2*1 1/2"*4mm, steel A36 | |matspec=Angle 1 1/2*1 1/2"*4mm, steel A36 | ||

|matpdffile=oho_cm3_1.4_Angulo pata detras mesa.pdf | |matpdffile=oho_cm3_1.4_Angulo pata detras mesa.pdf | ||

}} | }}{{ProjektMaterials | ||

{{ProjektMaterials | |||

|matpartnumber=1.5 | |matpartnumber=1.5 | ||

|matquantity=2 | |matquantity=2 | ||

| Line 601: | Line 579: | ||

|matspec=Angle 1 1/2*1 1/2"*4mm, steel A36 | |matspec=Angle 1 1/2*1 1/2"*4mm, steel A36 | ||

|matpdffile=oho_cm3_1.5_Angulo refuerzo de mesa.pdf | |matpdffile=oho_cm3_1.5_Angulo refuerzo de mesa.pdf | ||

}} | }}{{ProjektMaterials | ||

{{ProjektMaterials | |||

|matpartnumber=1.6 | |matpartnumber=1.6 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 609: | Line 586: | ||

|matspec=Angle 1 1/2*1 1/2"*4mm, steel A36 | |matspec=Angle 1 1/2*1 1/2"*4mm, steel A36 | ||

|matpdffile=oho_cm3_1.6_Angulo2 refuerzo mesa.pdf | |matpdffile=oho_cm3_1.6_Angulo2 refuerzo mesa.pdf | ||

}} | }}{{ProjektMaterials | ||

{{ProjektMaterials | |||

|matpartnumber=1.7 | |matpartnumber=1.7 | ||

|matquantity=4 | |matquantity=4 | ||

| Line 617: | Line 593: | ||

|matspec=Plate 1 1/2*3/16", A36 steel | |matspec=Plate 1 1/2*3/16", A36 steel | ||

|matpdffile=oho_cm3_1.7_Lamina de anclaje.pdf | |matpdffile=oho_cm3_1.7_Lamina de anclaje.pdf | ||

}} | }}{{ProjektMaterials | ||

{{ProjektMaterials | |||

|matpartnumber=2.0 | |matpartnumber=2.0 | ||

|matquantity=1 | |matquantity=1 | ||

|matdesc=Shear body | |matdesc=Shear body | ||

|matpdffile=oho_cm3_2.0_Cuerpo de cizalla.pdf | |matpdffile=oho_cm3_2.0_Cuerpo de cizalla.pdf | ||

}} | }}{{ProjektMaterials | ||

{{ProjektMaterials | |||

|matpartnumber=2.1 | |matpartnumber=2.1 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 633: | Line 605: | ||

|matspec=Plate 16mm, steel A36 | |matspec=Plate 16mm, steel A36 | ||

|matpdffile=oho_cm3_2.1_Lamina base inferior.pdf | |matpdffile=oho_cm3_2.1_Lamina base inferior.pdf | ||

}} | }}{{ProjektMaterials | ||

{{ProjektMaterials | |||

|matpartnumber=2.2 | |matpartnumber=2.2 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 641: | Line 612: | ||

|matspec=Plate 16mm, steel A36 | |matspec=Plate 16mm, steel A36 | ||

|matpdffile=oho_cm3_2.2_Centro de soportes b.pdf | |matpdffile=oho_cm3_2.2_Centro de soportes b.pdf | ||

}} | }}{{ProjektMaterials | ||

{{ProjektMaterials | |||

|matpartnumber=2.3 | |matpartnumber=2.3 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 649: | Line 619: | ||

|matspec=Plate 16mm, steel A36 | |matspec=Plate 16mm, steel A36 | ||

|matpdffile=oho_cm3_2.3_Lamina base superior.pdf | |matpdffile=oho_cm3_2.3_Lamina base superior.pdf | ||

}} | }}{{ProjektMaterials | ||

{{ProjektMaterials | |||

|matpartnumber=2.4 | |matpartnumber=2.4 | ||

|matquantity=2 | |matquantity=2 | ||

| Line 657: | Line 626: | ||

|matspec=Flat bar 1 1/2*3/16", steel A36 | |matspec=Flat bar 1 1/2*3/16", steel A36 | ||

|matpdffile=oho_cm3_2.4_Lamina apoyo.pdf | |matpdffile=oho_cm3_2.4_Lamina apoyo.pdf | ||

}} | }}{{ProjektMaterials | ||

{{ProjektMaterials | |||

|matpartnumber=2.5 | |matpartnumber=2.5 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 665: | Line 633: | ||

|matspec=Square bar 1/2", steel A36 | |matspec=Square bar 1/2", steel A36 | ||

|matpdffile=oho_cm3_2.5_Soporte1 de cuchilla.pdf | |matpdffile=oho_cm3_2.5_Soporte1 de cuchilla.pdf | ||

}} | }}{{ProjektMaterials | ||

{{ProjektMaterials | |||

|matpartnumber=2.6 | |matpartnumber=2.6 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 673: | Line 640: | ||

|matspec=Square bar 1/2", steel A36 | |matspec=Square bar 1/2", steel A36 | ||

|matpdffile=oho_cm3_2.6_Soporte2 de cuchilla.pdf | |matpdffile=oho_cm3_2.6_Soporte2 de cuchilla.pdf | ||

}} | }}{{ProjektMaterials | ||

{{ProjektMaterials | |||

|matpartnumber=2.7 | |matpartnumber=2.7 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 681: | Line 647: | ||

|matspec=Leaf spring 10mm, steel 9260, optional 13mm | |matspec=Leaf spring 10mm, steel 9260, optional 13mm | ||

|matpdffile=oho_cm3_2.7_Cuchilla movil.pdf | |matpdffile=oho_cm3_2.7_Cuchilla movil.pdf | ||

}} | }}{{ProjektMaterials | ||

{{ProjektMaterials | |||

|matpartnumber=2.8 | |matpartnumber=2.8 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 689: | Line 654: | ||

|matspec=Leaf spring 10mm, steel 9260, optional 13mm | |matspec=Leaf spring 10mm, steel 9260, optional 13mm | ||

|matpdffile=oho_cm3_2.8_Cuchilla fija.pdf | |matpdffile=oho_cm3_2.8_Cuchilla fija.pdf | ||

}} | }}{{ProjektMaterials | ||

{{ProjektMaterials | |||

|matpartnumber=2.9 | |matpartnumber=2.9 | ||

|matquantity=2 | |matquantity=2 | ||

| Line 696: | Line 660: | ||

|matparttype=standard | |matparttype=standard | ||

|matspec=Hex bolt 1/2*2 1/4" NC | |matspec=Hex bolt 1/2*2 1/4" NC | ||

}}{{ProjektMaterials | |||

}} | |||

{{ProjektMaterials | |||

|matpartnumber=2.10 | |matpartnumber=2.10 | ||

|matquantity=6 | |matquantity=6 | ||

| Line 704: | Line 666: | ||

|matparttype=standard | |matparttype=standard | ||

|matspec=Hexagonal screw 3/8*1 1/8" NC, optional l 1" hexagonal screw | |matspec=Hexagonal screw 3/8*1 1/8" NC, optional l 1" hexagonal screw | ||

}}{{ProjektMaterials | |||

}} | |||

{{ProjektMaterials | |||

|matpartnumber=2.11 | |matpartnumber=2.11 | ||

|matquantity=4 | |matquantity=4 | ||

| Line 712: | Line 672: | ||

|matparttype=standard | |matparttype=standard | ||

|matspec=Hex nut 1/2" NC | |matspec=Hex nut 1/2" NC | ||

}}{{ProjektMaterials | |||

}} | |||

{{ProjektMaterials | |||

|matpartnumber=2.12 | |matpartnumber=2.12 | ||

|matquantity=2 | |matquantity=2 | ||

| Line 720: | Line 678: | ||

|matparttype=standard | |matparttype=standard | ||

|matspec=Flat washer for 1/2" NC | |matspec=Flat washer for 1/2" NC | ||

}}{{ProjektMaterials | |||

}} | |||

{{ProjektMaterials | |||

|matpartnumber=2.13 | |matpartnumber=2.13 | ||

|matquantity=2 | |matquantity=2 | ||

| Line 728: | Line 684: | ||

|matparttype=standard | |matparttype=standard | ||

|matspec=Flat washer for 3/8" NC | |matspec=Flat washer for 3/8" NC | ||

}}{{ProjektMaterials | |||

}} | |||

{{ProjektMaterials | |||

|matpartnumber=2.14 | |matpartnumber=2.14 | ||

|matquantity=4 | |matquantity=4 | ||

| Line 736: | Line 690: | ||

|matparttype=standard | |matparttype=standard | ||

|matspec=Hex nut 3/8" NC | |matspec=Hex nut 3/8" NC | ||

}}{{ProjektMaterials | |||

}} | |||

{{ProjektMaterials | |||

|matpartnumber=2.15 | |matpartnumber=2.15 | ||

|matquantity=2 | |matquantity=2 | ||

| Line 745: | Line 697: | ||

|matspec=Round bar 3/4", A36 steel | |matspec=Round bar 3/4", A36 steel | ||

|matpdffile=oho_cm3_2.15_Casquillo de apoyo.pdf | |matpdffile=oho_cm3_2.15_Casquillo de apoyo.pdf | ||

}} | }}{{ProjektMaterials | ||

{{ProjektMaterials | |||

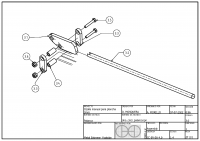

|matpartnumber=3.0 | |matpartnumber=3.0 | ||

|matquantity=1 | |matquantity=1 | ||

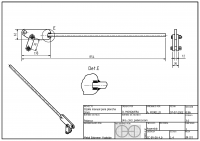

|matdesc=Lever | |matdesc=Lever | ||

|matpdffile=oho_cm3_3.0_Palanca.pdf | |matpdffile=oho_cm3_3.0_Palanca.pdf | ||

}} | }}{{ProjektMaterials | ||

{{ProjektMaterials | |||

|matpartnumber=3.1 | |matpartnumber=3.1 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 761: | Line 709: | ||

|matspec=Plate 12mm, A36 steel | |matspec=Plate 12mm, A36 steel | ||

|matpdffile=oho_cm3_3.1_Brazo de palanca.pdf | |matpdffile=oho_cm3_3.1_Brazo de palanca.pdf | ||

}} | }}{{ProjektMaterials | ||

{{ProjektMaterials | |||

|matpartnumber=3.2 | |matpartnumber=3.2 | ||

|matquantity=1 | |matquantity=1 | ||

| Line 769: | Line 716: | ||

|matspec=Plate 3/16" or 3/4" round bar | |matspec=Plate 3/16" or 3/4" round bar | ||

|matpdffile=oho_cm3_3.2_Barra de palanca.pdf | |matpdffile=oho_cm3_3.2_Barra de palanca.pdf | ||

}} | }}{{ProjektMaterials | ||

{{ProjektMaterials | |||

|matpartnumber=3.3 | |matpartnumber=3.3 | ||

|matquantity=2 | |matquantity=2 | ||

| Line 777: | Line 723: | ||

|matspec=Plate 12mm, A36 steel | |matspec=Plate 12mm, A36 steel | ||

|matpdffile=oho_cm3_3.3_Nervios de palanca.pdf | |matpdffile=oho_cm3_3.3_Nervios de palanca.pdf | ||

}} | }}{{ProjektMaterials | ||

{{ProjektMaterials | |||

|matpartnumber=3.4 | |matpartnumber=3.4 | ||

|matquantity=2 | |matquantity=2 | ||

| Line 785: | Line 730: | ||

|matspec=3/4" round bar, A36 steel | |matspec=3/4" round bar, A36 steel | ||

|matpdffile=oho_cm3_3.4_Casquillos de palanca.pdf | |matpdffile=oho_cm3_3.4_Casquillos de palanca.pdf | ||

}} | }}{{ProjektMaterials | ||

{{ProjektMaterials | |||

|matpartnumber=3.5 | |matpartnumber=3.5 | ||

|matquantity=2 | |matquantity=2 | ||

| Line 792: | Line 736: | ||

|matparttype=standard | |matparttype=standard | ||

|matspec=Hex bolt 1/2*2 1/2" NC | |matspec=Hex bolt 1/2*2 1/2" NC | ||

}}{{ProjektMaterials | |||

}} | |||

{{ProjektMaterials | |||

|matpartnumber=3.6 | |matpartnumber=3.6 | ||

|matquantity=4 | |matquantity=4 | ||

| Line 800: | Line 742: | ||

|matparttype=standard | |matparttype=standard | ||

|matspec=Hex nut 1/2" NC | |matspec=Hex nut 1/2" NC | ||

}} | }} | ||

|certificate_requested=No | |certificate_requested=No | ||

Revision as of 10:45, 10 April 2023

|

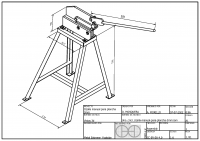

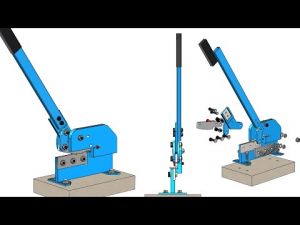

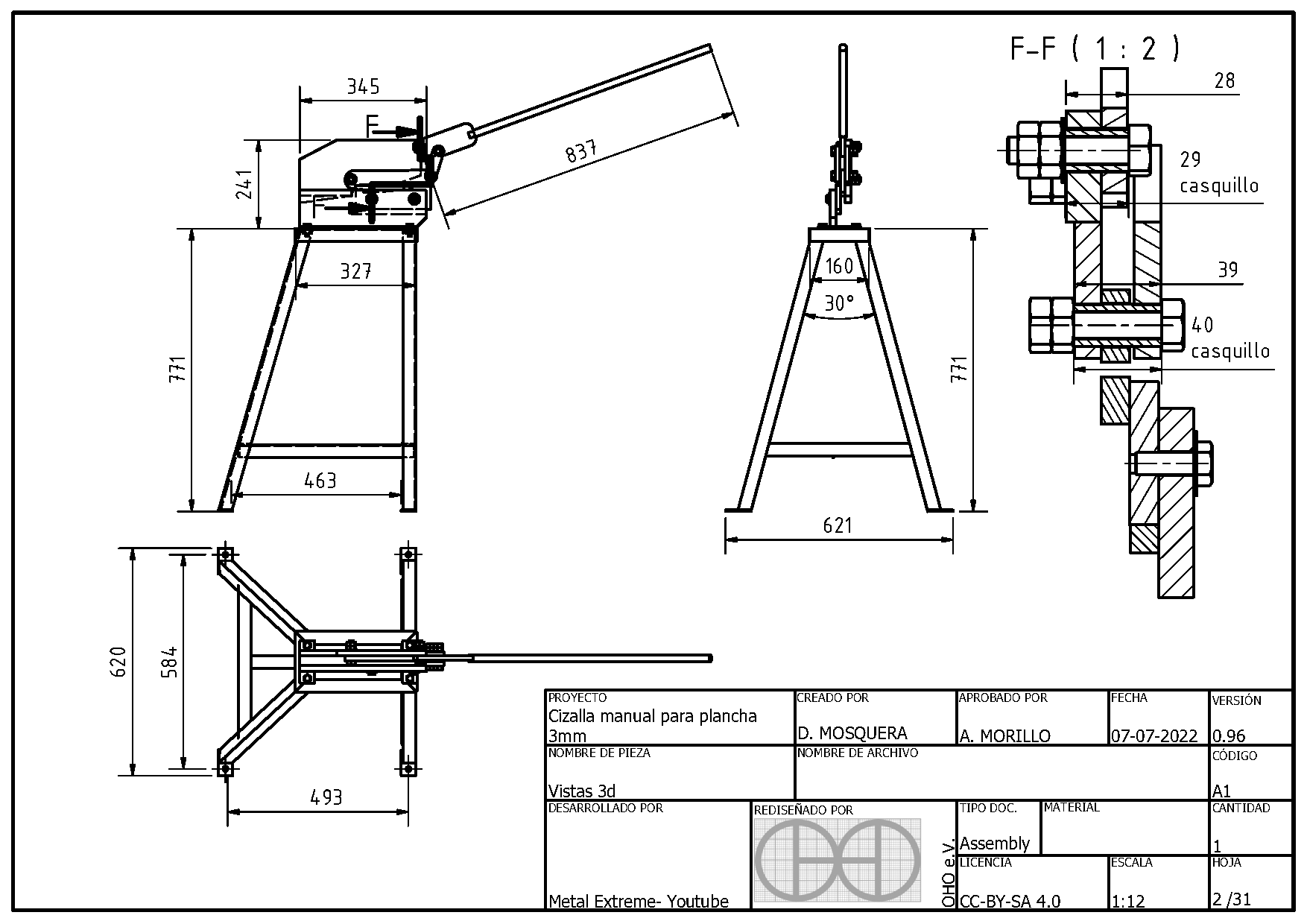

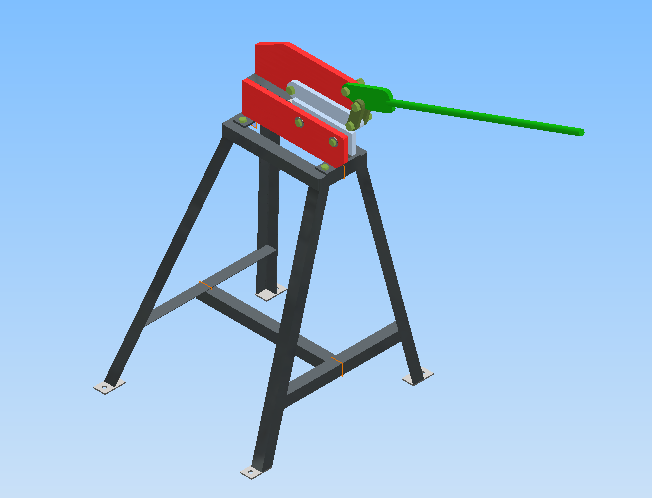

Manual shearing machine for 3mm plate Basic Data Category: Shears URL (first publication): https://www.youtube.com/watch?v=Oz5MzN0Pc_M Keywords: cutting, shear, diy, metal, machine, workshop, open source, spring steel, hardening License: CC BY-NC-SA 4.0 Organization: OHO Project status: Active Certification status: In process Technical documentation Maturity of the project: prototype

Contains PDF-drawings: Yes CAD files are editable: Yes Assembly instructions are published: Yes Bill of materials is published: Yes

yes yes

|

Description

Technical documentation

PDF plans | |

|

|

Files: | |

CAD files | |

|

|

Files: | |

Project development | |

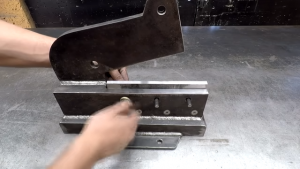

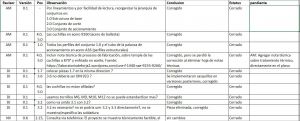

Based on the DIN 2221 standard, among others, OHO has established a series of stages in which the satisfactory completion of this project was carried out 1. Feasibility study

2. Market analisis and requirements

3. Search & analisis DIY technologies

4. Development & documentation

5. Manufacturing, tests and improvements

6. Certification DIN Spec 3105

| |

+ General Reviews

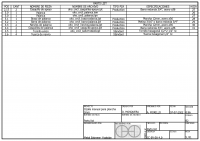

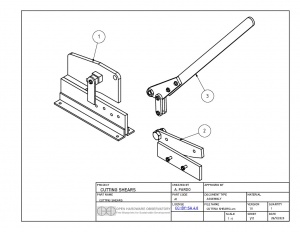

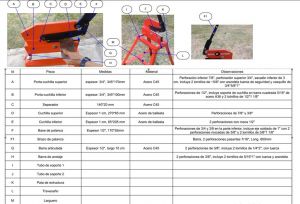

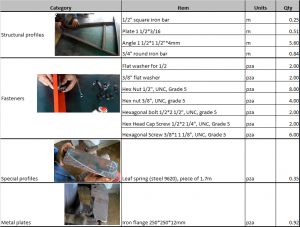

Parts list

| Pos. | Qty. | Part Name | Part code | Part Type | Specifications | Review Status | Show All Comments | |

|---|---|---|---|---|---|---|---|---|

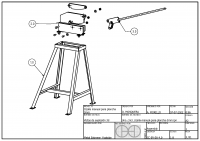

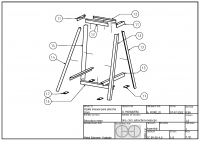

| A1 | 1 | 3D views | ||||||

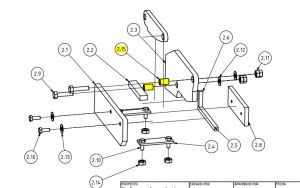

| A2 | 1 | Exloded 3D views | ||||||

| B | Parts list | |||||||

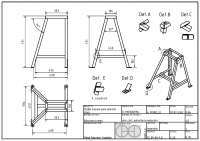

| 1.0 | 1 | Table structure | ||||||

| 1.1 | 2 | Table angle | Production | Angle 1 1/2*1 1/2"*4mm, A36 steel | ||||

| 1.2 | 2 | Table side angle | Production | Angle 1 1/2*1 1/2"*4mm, A36 steel | ||||

| 1.3 | 2 | Table front angle | Production | Angle 1 1/2*1 1/2"*4mm, steel A36 | ||||

| 1.4 | 2 | Table back leg angle | Production | Angle 1 1/2*1 1/2"*4mm, steel A36 | ||||

| 1.5 | 2 | Table reinforcement angle | Production | Angle 1 1/2*1 1/2"*4mm, steel A36 | ||||

| 1.6 | 1 | Angle2 table reinforcement | Production | Angle 1 1/2*1 1/2"*4mm, steel A36 | ||||

| 1.7 | 4 | Anchor plate | Production | Plate 1 1/2*3/16", A36 steel | ||||

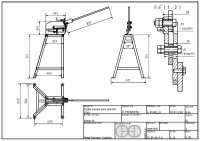

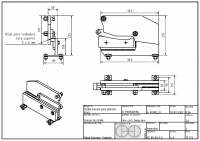

| 2.0 | 1 | Shear body | ||||||

| 2.1 | 1 | Lower base plate | Production | Plate 16mm, steel A36 | ||||

| 2.2 | 1 | Support center b | Production | Plate 16mm, steel A36 | ||||

| 2.3 | 1 | Upper base plate | Production | Plate 16mm, steel A36 | ||||

| 2.4 | 2 | Support plate | Production | Flat bar 1 1/2*3/16", steel A36 | ||||

| 2.5 | 1 | Blade support1 | Production | Square bar 1/2", steel A36 | ||||

| 2.6 | 1 | Blade support2 | Production | Square bar 1/2", steel A36 | ||||

| 2.7 | 1 | Mobile blade | Production | Leaf spring 10mm, steel 9260, optional 13mm | ||||

| 2.8 | 1 | Fixed blade | Production | Leaf spring 10mm, steel 9260, optional 13mm | ||||

| 2.9 | 2 | Screw for pivot | Standard | Hex bolt 1/2*2 1/4" NC | ||||

| 2.10 | 6 | Fixed blade screw | Standard | Hexagonal screw 3/8*1 1/8" NC, optional l 1" hexagonal screw | ||||

| 2.11 | 4 | Pivot nut | Standard | Hex nut 1/2" NC | ||||

| 2.12 | 2 | Washer2 | Standard | Flat washer for 1/2" NC | ||||

| 2.13 | 2 | Washer | Standard | Flat washer for 3/8" NC | ||||

| 2.14 | 4 | Support nut | Standard | Hex nut 3/8" NC | ||||

| 2.15 | 2 | Support bushing | Production | Round bar 3/4", A36 steel | ||||

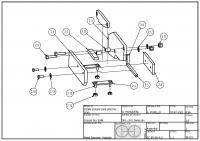

| 3.0 | 1 | Lever | ||||||

| 3.1 | 1 | Lever arm | Production | Plate 12mm, A36 steel | ||||

| 3.2 | 1 | Lever bar | Production | Plate 3/16" or 3/4" round bar | ||||

| 3.3 | 2 | Lever arm | Production | Plate 12mm, A36 steel | ||||

| 3.4 | 2 | Lever bushing | Production | 3/4" round bar, A36 steel | ||||

| 3.5 | 2 | Union screw | Standard | Hex bolt 1/2*2 1/2" NC | ||||

| 3.6 | 4 | Rib nut | Standard | Hex nut 1/2" NC | ||||