Difference between revisions of "Manual shearing machine for 3mm plate"

From OHO - search engine for sustainable open hardware projects

Inddigital (talk | contribs) ((by SublimeText.Mediawiker)) |

Inddigital (talk | contribs) ((by SublimeText.Mediawiker)) |

||

| Line 110: | Line 110: | ||

<hr> | <hr> | ||

<!-- <p>Test</p> --> | <!-- <p>Test</p> --> | ||

<ul> | |||

< | <li>Selection of projects</li> | ||

< | <li> | ||

[[File:Pdc_process_p1-1.png|100px|thumb|<small>'''Basic data'''</small>]] | Equipment scale <br> | ||

<table> | |||

< | <td width="75%">Can it be manufactured in small workshops?</td> | ||

< | <td>[[File:Pdc_process_p1-1.png|100px|thumb|<small>'''Basic data'''</small>]]</td> | ||

< | </table> | ||

</li> | |||

<li>Access to materials</li> | |||

<li>Access to manufacturing processes</li> | |||

<li>Examples</li> | |||

</ul> | |||

<br> | <br> | ||

Revision as of 23:08, 16 January 2023

|

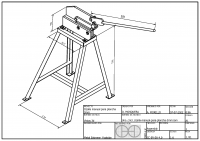

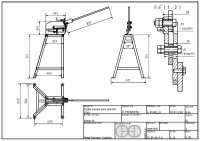

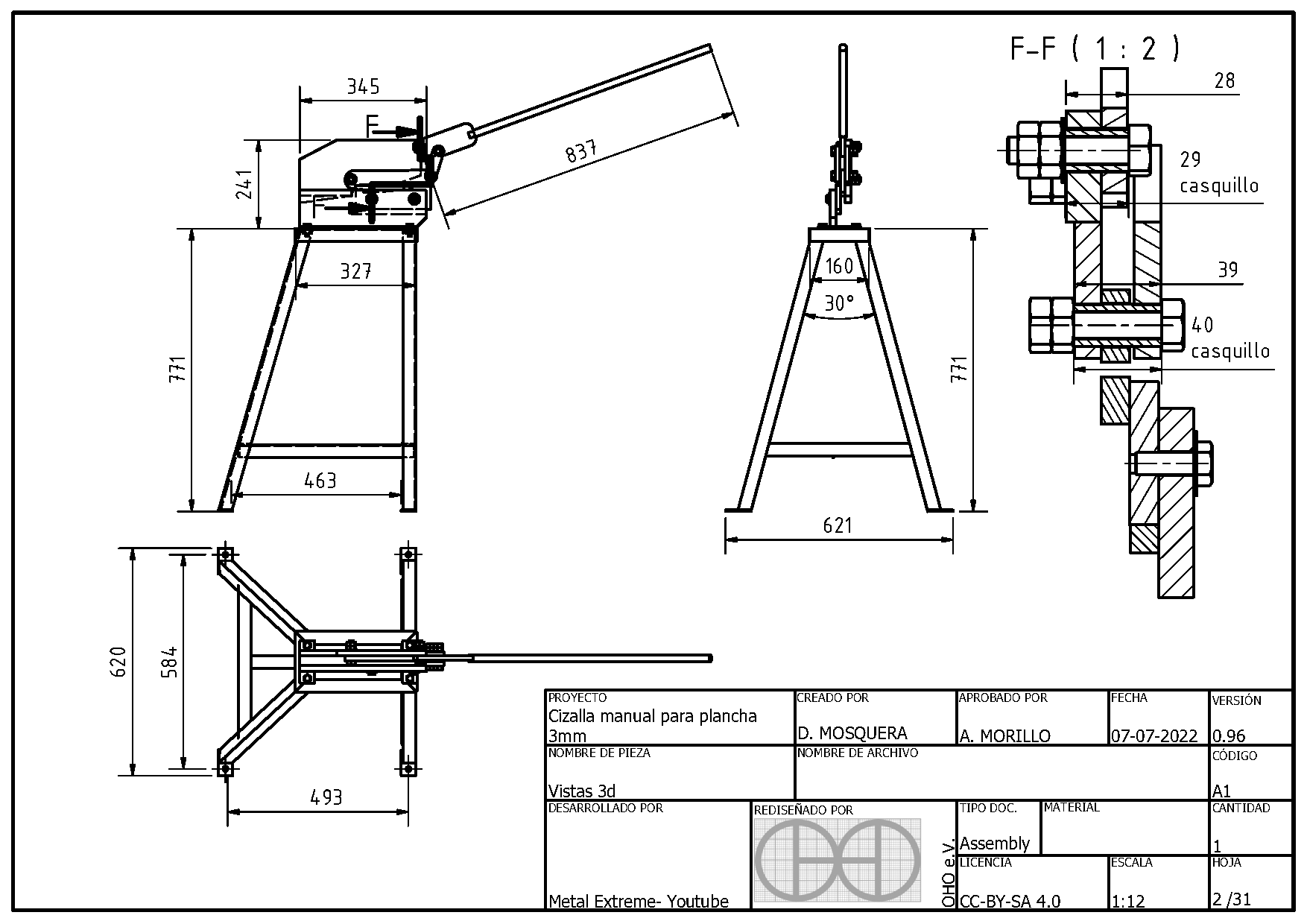

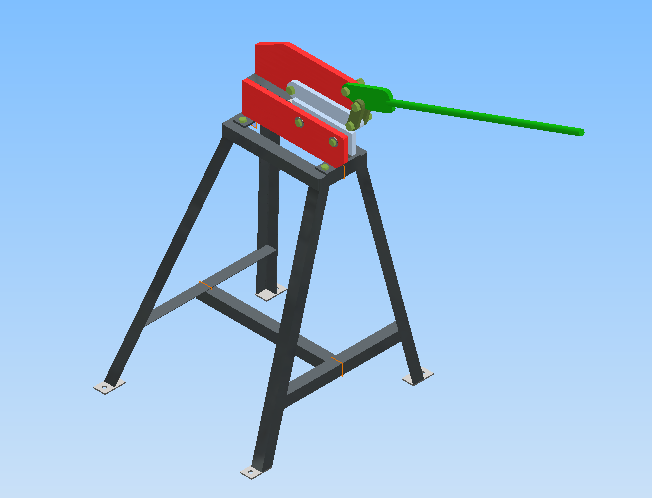

Manual shearing machine for 3mm plate Basic Data Category: Shears URL (first publication): https://www.youtube.com/watch?v=Oz5MzN0Pc_M Keywords: cutting, shear, diy, metal, machine, workshop, open source, spring steel, hardening License: CC BY-NC-SA 4.0 Organization: OHO Project status: Active

Technical documentation Maturity of the project: prototype

Contains PDF-drawings: Yes CAD files are editable: Yes Assembly instructions are published: Yes Bill of materials is published: Yes

yes yes

|

Description

Manufacturing project

Technical documentation

PDF plans | |

|

|

Files: | |

CAD files | |

|

|

Files: | |

Project Development | ||

Based on the DIN 2221 standard, among others, OHO has established a series of stages in which the satisfactory completion of this project was carried out, click here to see the complete process

Preliminary study

Market study, requirementsTest

Search & analisis DIY technologiesTest

Development & documentationTest

Manufacturing & improvementTest

Certif. accord. to DIN Spec 3105Test

PromotionTest | ||

+ General Reviews

Parts list

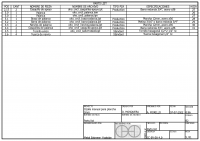

| Pos. | Qty. | Part Name | Part code | Part Type | Specifications | Review Status | Show All Comments | |

|---|---|---|---|---|---|---|---|---|

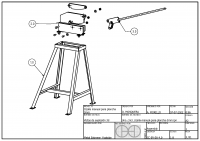

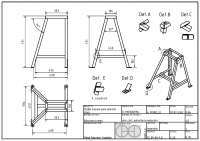

| A1 | 1 | 3D views | ||||||

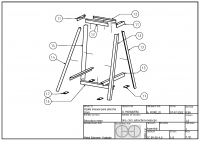

| A2 | 1 | Exloded 3D views | ||||||

| B | Parts list | |||||||

| 1.0 | 1 | Table structure | ||||||

| 1.1 | 2 | Table angle | Production | Angle 1 1/2*1 1/2"*4mm, A36 steel | ||||

| 1.2 | 2 | Table side angle | Production | Angle 1 1/2*1 1/2"*4mm, A36 steel | ||||

| 1.3 | 2 | Table front angle | Production | Angle 1 1/2*1 1/2"*4mm, steel A36 | ||||

| 1.4 | 2 | Table back leg angle | Production | Angle 1 1/2*1 1/2"*4mm, steel A36 | ||||

| 1.5 | 2 | Table reinforcement angle | Production | Angle 1 1/2*1 1/2"*4mm, steel A36 | ||||

| 1.6 | 1 | Angle2 table reinforcement | Production | Angle 1 1/2*1 1/2"*4mm, steel A36 | ||||

| 1.7 | 4 | Anchor plate | Production | Plate 1 1/2*3/16", A36 steel | ||||

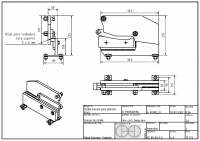

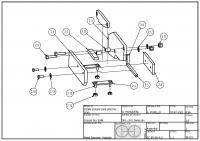

| 2.0 | 1 | Shear body | ||||||

| 2.1 | 1 | Lower base plate | Production | Plate 16mm, steel A36 | ||||

| 2.2 | 1 | Support center b | Production | Plate 16mm, steel A36 | ||||

| 2.3 | 1 | Upper base plate | Production | Plate 16mm, steel A36 | ||||

| 2.4 | 2 | Support plate | Production | Flat bar 1 1/2*3/16", steel A36 | ||||

| 2.5 | 1 | Blade support1 | Production | Square bar 1/2", steel A36 | ||||

| 2.6 | 1 | Blade support2 | Production | Square bar 1/2", steel A36 | ||||

| 2.7 | 1 | Mobile blade | Production | Leaf spring 10mm, steel 9260, optional 13mm | ||||

| 2.8 | 1 | Fixed blade | Production | Leaf spring 10mm, steel 9260, optional 13mm | ||||

| 2.9 | 2 | Screw for pivot | Standard | Hex bolt 1/2*2 1/4" NC | ||||

| 2.10 | 6 | Fixed blade screw | Standard | Hexagonal screw 3/8*1 1/8" NC, optional l 1" hexagonal screw | ||||

| 2.11 | 4 | Pivot nut | Standard | Hex nut 1/2" NC | ||||

| 2.12 | 2 | Washer2 | Standard | Flat washer for 1/2" NC | ||||

| 2.13 | 2 | Washer | Standard | Flat washer for 3/8" NC | ||||

| 2.14 | 4 | Support nut | Standard | Hex nut 3/8" NC | ||||

| 2.15 | 2 | Support bushing | Production | Round bar 3/4", A36 steel | ||||

| 3.0 | 1 | Lever | ||||||

| 3.1 | 1 | Lever arm | Production | Plate 12mm, A36 steel | ||||

| 3.2 | 1 | Lever bar | Production | Plate 3/16" or 3/4" round bar | ||||

| 3.3 | 2 | Lever arm | Production | Plate 12mm, A36 steel | ||||

| 3.4 | 2 | Lever bushing | Production | 3/4" round bar, A36 steel | ||||

| 3.5 | 2 | Union screw | Standard | Hex bolt 1/2*2 1/2" NC | ||||

| 3.6 | 4 | Rib nut | Standard | Hex nut 1/2" NC | ||||