Difference between revisions of "Darrieus Turbine - 2m combined"

Inddigital (talk | contribs) ((by SublimeText.Mediawiker)) |

|||

| (7 intermediate revisions by one other user not shown) | |||

| Line 2: | Line 2: | ||

|Images={{ProjektImages | |Images={{ProjektImages | ||

|projectimage=oho_tdc2_render4.jpg | |projectimage=oho_tdc2_render4.jpg | ||

}}{{ProjektImages | |||

|projectimage=oho_tdc2_render3.jpg | |||

}}{{ProjektImages | }}{{ProjektImages | ||

|projectimage=oho_tdc2_001.jpg | |projectimage=oho_tdc2_001.jpg | ||

| Line 34: | Line 36: | ||

|firstin=https://youtube.com/shorts/Alf6EOTmlHM?feature=share | |firstin=https://youtube.com/shorts/Alf6EOTmlHM?feature=share | ||

|trans_status=WT | |trans_status=WT | ||

|desc= | |desc=__TOC__ | ||

__TOC__ | |||

<!-- Manufacturing project, Supported by: GLS Treuhand Stiftung Neue Energie --> | <!-- Manufacturing project, Supported by: GLS Treuhand Stiftung Neue Energie --> | ||

|licence=CCBYSA40 | |licence=CCBYSA40 | ||

| Line 53: | Line 54: | ||

|versioning_system=yes | |versioning_system=yes | ||

|contains_pdf_drawings=yes | |contains_pdf_drawings=yes | ||

|technology_readyness_level= | |technology_readyness_level=5 | ||

|TechDoc={{ProjektComponent | |TechDoc={{ProjektComponent | ||

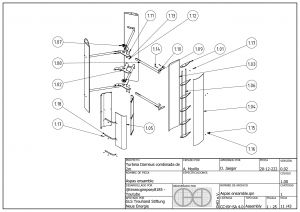

|cmptitle=PDF plans | |cmptitle=PDF plans | ||

| Line 60: | Line 61: | ||

}}{{ProjektComponent | }}{{ProjektComponent | ||

|cmptitle=CAD files | |cmptitle=CAD files | ||

|cmpimage= | |cmpimage=oho_tdc2_render7.jpg | ||

|cmpfile1=oho_tdc2_STP-files.zip | |cmpfile1=oho_tdc2_STP-files.zip | ||

|cmpfile2=oho_tdc2_DWG-files.zip | |cmpfile2=oho_tdc2_DWG-files.zip | ||

| Line 67: | Line 68: | ||

|cmptitle=Technical development | |cmptitle=Technical development | ||

|cmpimage=oho_tdc2_dt1.jpg | |cmpimage=oho_tdc2_dt1.jpg | ||

|cmpfile1=Turbina eólica Darrieus 2022_detalles de desarrollo técnico_0.05.pdf | |cmpfile1=Turbina eólica Darrieus 2022_detalles de desarrollo técnico_0.05.pdf<!-- | ||

<!-- |cmpfile2=Darrieus 2022 desarrollo técnico 0.02.xls --> | |cmpfile2=Darrieus 2022 desarrollo técnico 0.02.xls --> | ||

}} | }}{{ProjektComponent | ||

{{ProjektComponent | |||

|cmptitle=Project development<!-- | |cmptitle=Project development<!-- | ||

|cmpimage=Oho_tdc2_imgref1.jpg --> | |cmpimage=Oho_tdc2_imgref1.jpg --> | ||

|cmpimg= | |cmpimg=Based on the DIN 2221 standard, among others, OHO has established a series of <i class="mw-customtoggle-div1" style="color:#1b599a;">stages</i> in which the satisfactory [[Processes_involved_in_Project_Development|completion of this project]] was carried out | ||

Based on the DIN 2221 standard, among others, OHO has established a series of <i class="mw-customtoggle-div1" style="color:#1b599a;">stages</i> in which the satisfactory [[Processes_involved_in_Project_Development|completion of this project]] was carried out | |||

<div style="margin:20px"></div> | <div style="margin:20px"></div> | ||

<div class="mw-collapsible" id="mw-customcollapsible-div1" data-origID="mw-customcollapsible-div1"><!-- mw-collapsed --> | <div class="mw-collapsible" id="mw-customcollapsible-div1" data-origID="mw-customcollapsible-div1" data-origID="mw-customcollapsible-div1"><!-- mw-collapsed --> | ||

==== 1 Feasibility study ==== | ==== 1 Feasibility study ==== | ||

----- | ----- | ||

| Line 277: | Line 275: | ||

</ul></div> | </ul></div> | ||

: See related comments: [[{{TALKPAGENAME}}|Discussion]] | : See related comments: [[{{TALKPAGENAME}}|Discussion]] | ||

<div style="margin:20px"></div> | <div style="margin:20px"></div> | ||

| Line 288: | Line 285: | ||

: Among some revised and improved aspects of the project, prior to the publication of the plans, we can mention: | : Among some revised and improved aspects of the project, prior to the publication of the plans, we can mention: | ||

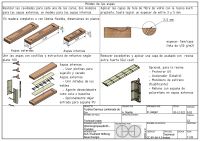

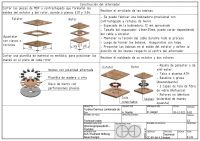

:: * Improvements in the presentation format of technical notes, they include illustrations on manufacturing | :: * Improvements in the presentation format of technical notes, they include illustrations on manufacturing | ||

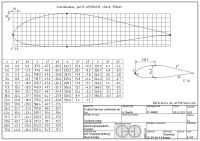

:: * | :: * Using a template with a grid for quick copying of the airfoil and manufacturing of the blades | ||

:: * | :: * Use of metal straps to hold the Savonius internal blade (version 0.02 - part 1.18) | ||

:: * Simplification in the H-shape of the turbine structure, without requiring tensioning trusses in it | |||

<div style="margin:20px"></div> | <div style="margin:20px"></div> | ||

==== 5. Manufacturing, tests and improvements ==== | ==== 5. Manufacturing, tests and improvements ==== | ||

| Line 296: | Line 294: | ||

* Workshop <br> Determination of the workshop for manufacturing: | * Workshop <br> Determination of the workshop for manufacturing: | ||

: This project is considered as belonging to the group of Appropriate Technologies, for which it has been developed with the intention of the greatest possible access to processes and materials by the developers, with a basic, moderately equipped workshop, however, it is necessary also have the following facilities: | : This project is considered as belonging to the group of Appropriate Technologies, for which it has been developed with the intention of the greatest possible access to processes and materials by the developers, with a basic, moderately equipped workshop, however, it is necessary also have the following facilities: | ||

:: * Tools and materials for working with | :: * Tools and materials for working with fiberglass | ||

:: * Tools for carving wood, in the case of | :: * Tools for carving wood, in the case of blade moulds | ||

:: * Adequate spaces, tools and equipment to carry out electrical work, in the case of generator connections and the associated electrical network | :: * Adequate spaces, tools and equipment to carry out electrical work, in the case of generator connections and the associated electrical network | ||

: Although these conditions do not pose a greater difficulty during manufacturing, it is left to the developer's discretion to choose between carrying out this work or requesting the services of a third party to guarantee a professional work | : Although these conditions do not pose a greater difficulty during manufacturing, it is left to the developer's discretion to choose between carrying out this work or requesting the services of a third party to guarantee a professional work | ||

The purchasing, prototype manufacturing, testing, and documentation updating sub-processes, will be developed once the manufacturing stage is completed | The purchasing, prototype manufacturing, testing, and documentation updating sub-processes, will be developed once the manufacturing stage is completed | ||

<! | <!-- * Purchase | ||

[[File:Oho_tdc2_materials-list1.png|300px|thumb]] | [[File:Oho_tdc2_materials-list1.png|300px|thumb]] | ||

: Purchase of materials and components: | : Purchase of materials and components: | ||

| Line 329: | Line 327: | ||

** Pieces 2.5 and 2.6, manufactured in 1/2" square bar, available in the workshop | ** Pieces 2.5 and 2.6, manufactured in 1/2" square bar, available in the workshop | ||

** Mobile blade (piece 2.7), with dimensions adjusted according to the leaf spring piece achieved, recovered material | ** Mobile blade (piece 2.7), with dimensions adjusted according to the leaf spring piece achieved, recovered material | ||

:Plans are expected to be updated with these changes, in order to have accurate information regarding the equipment manufactured | :Plans are expected to be updated with these changes, in order to have accurate information regarding the equipment manufactured --> | ||

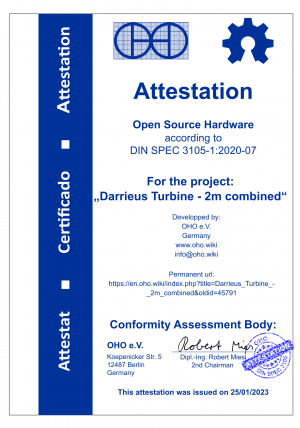

==== 6. Certification DIN Spec 3105 ==== | ==== 6. Certification DIN Spec 3105 ==== | ||

----- | ----- | ||

| Line 345: | Line 343: | ||

** [[User:Thehunter|Thehunter]] | ** [[User:Thehunter|Thehunter]] | ||

* Peer-reviews <br> Realization of the peer reviews, technical clarification, improvements: | * Peer-reviews <br> Realization of the peer reviews, technical clarification, improvements: | ||

:: | :: In the [[#Parts_list|Parts list]] section, necessary comments and discussions have been made by the assigned reviewers and the developer | ||

* Certificate <br> Issue of the certificate: <br> | |||

[[File:oho_tdc2_attestation_Darrieus-Turbine-2m-combined.png|300px|thumb|link=https://cdata.oho.wiki/images/7/78/Oho_tdc2_attestation_Darrieus-Turbine-2m-combined.pdf]] | |||

<!-- [[File:oho_cs14_attestation_solar-cooker-1-4m.png|300px|thumb|link=Media:Oho_cs14_attestation_solar-cooker-1-4m.pdf]] --> | |||

The project was reviewed by two reviewers from the OHO team. The review consisted of the following components: | |||

: * Completeness check: Checks if all required documents have been submitted. | |||

: * Review of the submitted documents: Checks if the information in the submitted documents is complete and correct. | |||

:: - Bill of materials | |||

:: - Are all parts and assemblies covered? | |||

:: - Are all quantities correct? | |||

:: - Are all required material specifications available? | |||

:: - Are all specifications for purchased parts and standard parts complete? | |||

: * Technical drawings | |||

:: - Are all the required views available? | |||

:: - Are all required dimensional data available? | |||

: * Suggestions for improvement | |||

Detail abot the review process: https://en.oho.wiki/wiki/Instructions_for_Reviewers | |||

Permanent Link: https://en.oho.wiki/index.php?title=Darrieus_Turbine_-_2m_combined&oldid=45791 | |||

<!-- | |||

<!~~ ==== 7. Promotion, formation ==== | <!~~ ==== 7. Promotion, formation ==== | ||

----- | ----- | ||

| Line 357: | Line 374: | ||

~~> | ~~> | ||

</div> --> | </div> --> | ||

}} | }} | ||

|Materials={{ProjektMaterials | |Materials={{ProjektMaterials | ||

|matpartnumber=A1 | |matpartnumber=A1 | ||

| Line 365: | Line 380: | ||

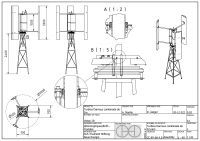

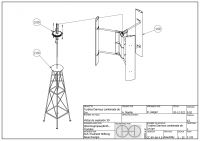

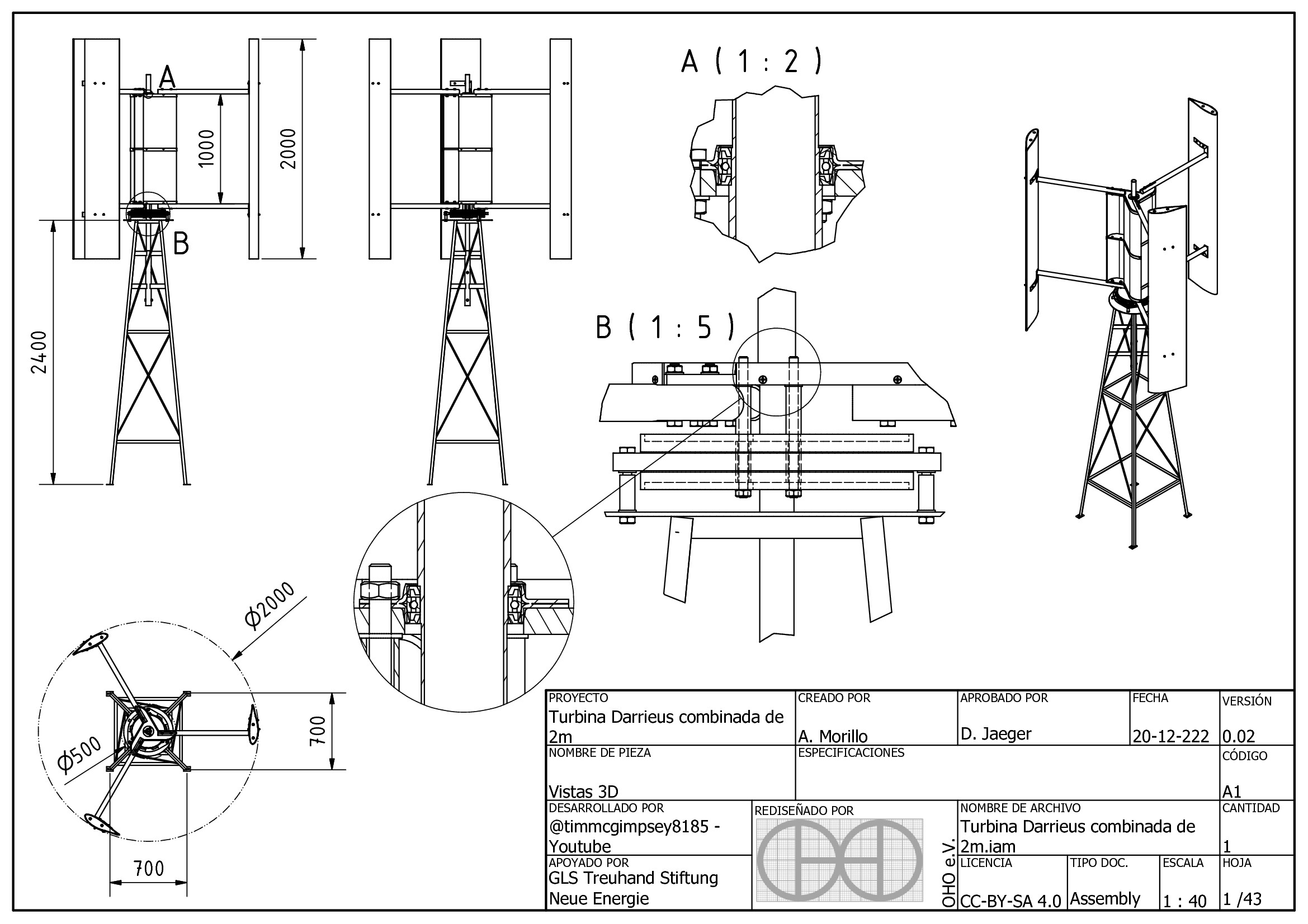

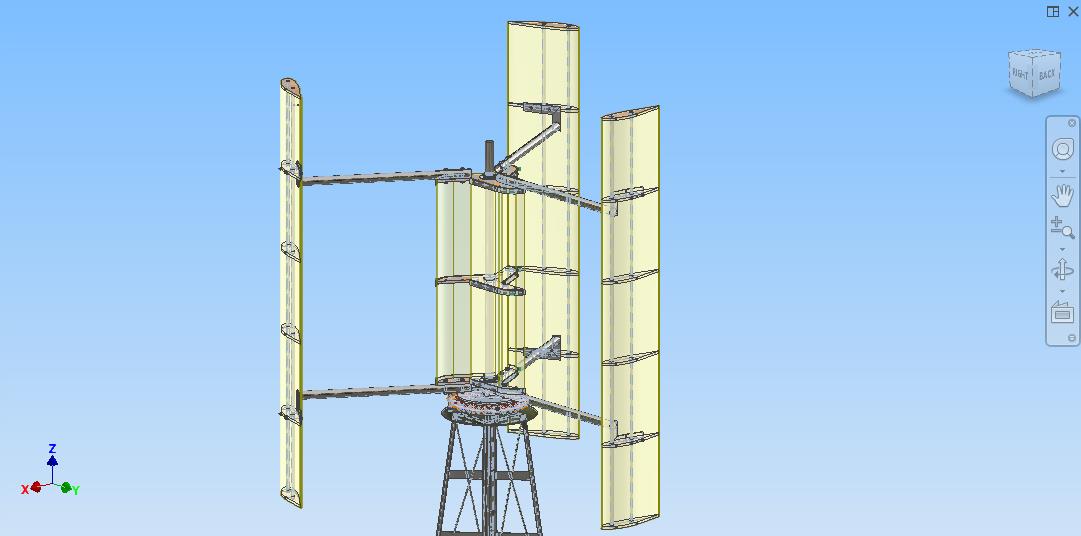

|matdesc=3D Views | |matdesc=3D Views | ||

|matpdffile=oho_tdc2_A1_Vistas 3D.pdf | |matpdffile=oho_tdc2_A1_Vistas 3D.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=A2 | |matpartnumber=A2 | ||

| Line 370: | Line 387: | ||

|matdesc=3D Explosion Views | |matdesc=3D Explosion Views | ||

|matpdffile=oho_tdc2_A2_Vistas de explosión 3D.pdf | |matpdffile=oho_tdc2_A2_Vistas de explosión 3D.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=B | |matpartnumber=B | ||

|matdesc=Parts list | |matdesc=Parts list | ||

|matpdffile=oho_tdc2_B_Parts list.pdf | |matpdffile=oho_tdc2_B_Parts list.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=C | |matpartnumber=C | ||

|matdesc=Technical notes | |matdesc=Technical notes | ||

|matpdffile=oho_tdc2_C_Technical notes.pdf | |matpdffile=oho_tdc2_C_Technical notes.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=1.00 | |matpartnumber=1.00 | ||

| Line 383: | Line 406: | ||

|matdesc=Blade assembly | |matdesc=Blade assembly | ||

|matpdffile=oho_tdc2_1.00_Aspas ensamble.pdf | |matpdffile=oho_tdc2_1.00_Aspas ensamble.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=1.01 | |matpartnumber=1.01 | ||

| Line 390: | Line 415: | ||

|matspec=Cedar or pine wood, 350*74*12mm | |matspec=Cedar or pine wood, 350*74*12mm | ||

|matpdffile=oho_tdc2_1.01_Costilla.pdf | |matpdffile=oho_tdc2_1.01_Costilla.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=1.02 | |matpartnumber=1.02 | ||

| Line 397: | Line 424: | ||

|matspec=Cedar or pine wood, 500*500*500*12mm | |matspec=Cedar or pine wood, 500*500*500*12mm | ||

|matpdffile=oho_tdc2_1.02_costilla2.pdf | |matpdffile=oho_tdc2_1.02_costilla2.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=1.03 | |matpartnumber=1.03 | ||

| Line 404: | Line 433: | ||

|matspec=Fiberglass and polyester resin, optional polyurethane filling. thickness: 3-5 mm | |matspec=Fiberglass and polyester resin, optional polyurethane filling. thickness: 3-5 mm | ||

|matpdffile=oho_tdc2_1.03_Capa de fibra1.pdf | |matpdffile=oho_tdc2_1.03_Capa de fibra1.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=1.04 | |matpartnumber=1.04 | ||

| Line 411: | Line 442: | ||

|matspec=Fiberglass and polyester resin, optional polyurethane filler. thickness: 3-5 mm | |matspec=Fiberglass and polyester resin, optional polyurethane filler. thickness: 3-5 mm | ||

|matpdffile=oho_tdc2_1.04_Capa de fibra2.pdf | |matpdffile=oho_tdc2_1.04_Capa de fibra2.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=1.05 | |matpartnumber=1.05 | ||

| Line 418: | Line 451: | ||

|matspec=Fiberglass and polyester resin, optional polyurethane filler. thickness: 3-5 mm. | |matspec=Fiberglass and polyester resin, optional polyurethane filler. thickness: 3-5 mm. | ||

|matpdffile=oho_tdc2_1.05_Capa de fibra3.pdf | |matpdffile=oho_tdc2_1.05_Capa de fibra3.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=1.06 | |matpartnumber=1.06 | ||

| Line 425: | Line 460: | ||

|matspec=Round tube 3/8", sch40 or similar, aluminum. | |matspec=Round tube 3/8", sch40 or similar, aluminum. | ||

|matpdffile=oho_tdc2_1.06_Refuerzo de aspa1.pdf | |matpdffile=oho_tdc2_1.06_Refuerzo de aspa1.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=1.07 | |matpartnumber=1.07 | ||

| Line 431: | Line 468: | ||

|matparttype=buy | |matparttype=buy | ||

|matspec=SKF 61808 2RZ bearing, 40*52*7mm, with double seal, double stuffing box HM4R and flanged housing | |matspec=SKF 61808 2RZ bearing, 40*52*7mm, with double seal, double stuffing box HM4R and flanged housing | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=1.08 | |matpartnumber=1.08 | ||

| Line 438: | Line 477: | ||

|matspec=Round tube 1 1/4", sch40 or similar, Iron | |matspec=Round tube 1 1/4", sch40 or similar, Iron | ||

|matpdffile=oho_tdc2_1.08_Brazo de aspa1.pdf | |matpdffile=oho_tdc2_1.08_Brazo de aspa1.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=1.09 | |matpartnumber=1.09 | ||

| Line 445: | Line 486: | ||

|matspec=Plate 1 1/2"*4mm*117mm | |matspec=Plate 1 1/2"*4mm*117mm | ||

|matpdffile=oho_tdc2_1.09_Soporte1 de aspa1.pdf | |matpdffile=oho_tdc2_1.09_Soporte1 de aspa1.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=1.10 | |matpartnumber=1.10 | ||

| Line 452: | Line 495: | ||

|matspec=Plate 1 1/2"*4mm*190mm | |matspec=Plate 1 1/2"*4mm*190mm | ||

|matpdffile=oho_tdc2_1.10_Soporte2 de aspa1.pdf | |matpdffile=oho_tdc2_1.10_Soporte2 de aspa1.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=1.11 | |matpartnumber=1.11 | ||

| Line 458: | Line 503: | ||

|matparttype=standard | |matparttype=standard | ||

|matspec=Hexagonal bolt 3/8*2 1/2", UNC, grade5 | |matspec=Hexagonal bolt 3/8*2 1/2", UNC, grade5 | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=1.12 | |matpartnumber=1.12 | ||

| Line 464: | Line 511: | ||

|matparttype=standard | |matparttype=standard | ||

|matspec=Hex nut 3/8", UNC, grade 5 | |matspec=Hex nut 3/8", UNC, grade 5 | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=1.13 | |matpartnumber=1.13 | ||

| Line 470: | Line 519: | ||

|matparttype=standard | |matparttype=standard | ||

|matspec=Flat washer for 3/8 | |matspec=Flat washer for 3/8 | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=1.14 | |matpartnumber=1.14 | ||

| Line 476: | Line 527: | ||

|matparttype=standard | |matparttype=standard | ||

|matspec=Hexagonal bolt 1/4*4*1" UNC, grade 5 | |matspec=Hexagonal bolt 1/4*4*1" UNC, grade 5 | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=1.15 | |matpartnumber=1.15 | ||

| Line 482: | Line 535: | ||

|matparttype=standard | |matparttype=standard | ||

|matspec=Hex Nut, 1/4", UNC, Grade 5 | |matspec=Hex Nut, 1/4", UNC, Grade 5 | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=1.16 | |matpartnumber=1.16 | ||

| Line 488: | Line 543: | ||

|matparttype=standard | |matparttype=standard | ||

|matspec=Flat washer for 1/4 | |matspec=Flat washer for 1/4 | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=1.17 | |matpartnumber=1.17 | ||

| Line 494: | Line 551: | ||

|matparttype=standard | |matparttype=standard | ||

|matspec=Drywall screw 1 1/2"#8 | |matspec=Drywall screw 1 1/2"#8 | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=1.18 | |matpartnumber=1.18 | ||

| Line 501: | Line 560: | ||

|matspec=Plate 1*1/8"*340mm | |matspec=Plate 1*1/8"*340mm | ||

|matpdffile=oho_tdc2_1.18_Fleje de aspa.pdf | |matpdffile=oho_tdc2_1.18_Fleje de aspa.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=2.00 | |matpartnumber=2.00 | ||

| Line 506: | Line 567: | ||

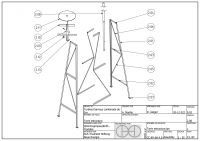

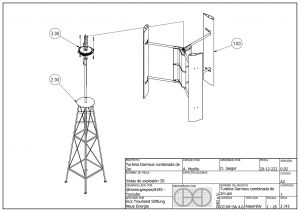

|matdesc=Tower structure | |matdesc=Tower structure | ||

|matpdffile=oho_tdc2_2.00_Torre estructura.pdf | |matpdffile=oho_tdc2_2.00_Torre estructura.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=2.01 | |matpartnumber=2.01 | ||

| Line 513: | Line 576: | ||

|matspec=Angle 1*1"*3mm*2422mm | |matspec=Angle 1*1"*3mm*2422mm | ||

|matpdffile=oho_tdc2_2.01_Puntal principal.pdf | |matpdffile=oho_tdc2_2.01_Puntal principal.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=2.02 | |matpartnumber=2.02 | ||

| Line 520: | Line 585: | ||

|matspec=Angle 1*1"*3mm*616mm | |matspec=Angle 1*1"*3mm*616mm | ||

|matpdffile=oho_tdc2_2.02_Travesaño1.pdf | |matpdffile=oho_tdc2_2.02_Travesaño1.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=2.03 | |matpartnumber=2.03 | ||

| Line 527: | Line 594: | ||

|matspec=Angle 1*1"*3mm*425mm | |matspec=Angle 1*1"*3mm*425mm | ||

|matpdffile=oho_tdc2_2.03_Travesaño2.pdf | |matpdffile=oho_tdc2_2.03_Travesaño2.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=2.04 | |matpartnumber=2.04 | ||

| Line 534: | Line 603: | ||

|matspec=Angle 1*1"*3mm*233mm | |matspec=Angle 1*1"*3mm*233mm | ||

|matpdffile=oho_tdc2_2.04_Travesaño3.pdf | |matpdffile=oho_tdc2_2.04_Travesaño3.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=2.05 | |matpartnumber=2.05 | ||

| Line 541: | Line 612: | ||

|matspec=Round iron bar D3/8"*1100mm | |matspec=Round iron bar D3/8"*1100mm | ||

|matpdffile=oho_tdc2_2.05_Cercha1.pdf | |matpdffile=oho_tdc2_2.05_Cercha1.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=2.06 | |matpartnumber=2.06 | ||

| Line 548: | Line 621: | ||

|matspec=Round iron bar D3/8"*1030mm | |matspec=Round iron bar D3/8"*1030mm | ||

|matpdffile=oho_tdc2_2.06_Cercha2.pdf | |matpdffile=oho_tdc2_2.06_Cercha2.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=2.07 | |matpartnumber=2.07 | ||

| Line 555: | Line 630: | ||

|matspec=Flat bar 1 1/2"* 4mm*60mm | |matspec=Flat bar 1 1/2"* 4mm*60mm | ||

|matpdffile=oho_tdc2_2.07_Oreja de anclaje.pdf | |matpdffile=oho_tdc2_2.07_Oreja de anclaje.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=2.08 | |matpartnumber=2.08 | ||

| Line 562: | Line 639: | ||

|matspec=Round iron pipe 1 1/4" sch40 (e 3.5mm)*2100mm, Cylindrical | |matspec=Round iron pipe 1 1/4" sch40 (e 3.5mm)*2100mm, Cylindrical | ||

|matpdffile=oho_tdc2_2.08_Poste central.pdf | |matpdffile=oho_tdc2_2.08_Poste central.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=2.09 | |matpartnumber=2.09 | ||

| Line 569: | Line 648: | ||

|matspec=Round iron pipe 1 1/2", sch40 (e 3.7mm) or similar, l 500mm | |matspec=Round iron pipe 1 1/2", sch40 (e 3.7mm) or similar, l 500mm | ||

|matpdffile=oho_tdc2_2.09_Guía de poste.pdf | |matpdffile=oho_tdc2_2.09_Guía de poste.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=2.10 | |matpartnumber=2.10 | ||

| Line 576: | Line 657: | ||

|matspec=Plate 1 1/2"*4mm*177mm | |matspec=Plate 1 1/2"*4mm*177mm | ||

|matpdffile=oho_tdc2_2.10_Soporte de poste.pdf | |matpdffile=oho_tdc2_2.10_Soporte de poste.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=2.11 | |matpartnumber=2.11 | ||

| Line 583: | Line 666: | ||

|matspec=Iron plate 450*450*5mm | |matspec=Iron plate 450*450*5mm | ||

|matpdffile=oho_tdc2_2.11_Soporte de estator.pdf | |matpdffile=oho_tdc2_2.11_Soporte de estator.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=2.12 | |matpartnumber=2.12 | ||

| Line 589: | Line 674: | ||

|matparttype=standard | |matparttype=standard | ||

|matspec=Hexagonal bolt 3/8*2 1/2" UNC, grade 5 | |matspec=Hexagonal bolt 3/8*2 1/2" UNC, grade 5 | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=2.13 | |matpartnumber=2.13 | ||

| Line 595: | Line 682: | ||

|matparttype=standard | |matparttype=standard | ||

|matspec=Hexagonal nut 3/8" UNC, grade 5 | |matspec=Hexagonal nut 3/8" UNC, grade 5 | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=3.00 | |matpartnumber=3.00 | ||

| Line 600: | Line 689: | ||

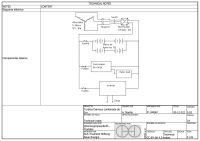

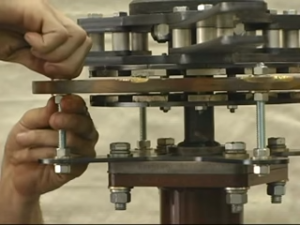

|matdesc=Alternator | |matdesc=Alternator | ||

|matpdffile=oho_tdc2_3.00_Alternador.pdf | |matpdffile=oho_tdc2_3.00_Alternador.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=3.01 | |matpartnumber=3.01 | ||

| Line 607: | Line 698: | ||

|matspec=Pre-mixed polyester resin with accelerator | |matspec=Pre-mixed polyester resin with accelerator | ||

|matpdffile=oho_tdc2_3.01_Casting del estator.pdf | |matpdffile=oho_tdc2_3.01_Casting del estator.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=3.02 | |matpartnumber=3.02 | ||

| Line 614: | Line 707: | ||

|matspec=Enameled copper cable, D 1.7 mm, 73 turns (for 12V), total weight: 3 kg | |matspec=Enameled copper cable, D 1.7 mm, 73 turns (for 12V), total weight: 3 kg | ||

|matpdffile=oho_tdc2_3.02_Coil.pdf | |matpdffile=oho_tdc2_3.02_Coil.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=3.03 | |matpartnumber=3.03 | ||

| Line 620: | Line 715: | ||

|matparttype=buy | |matparttype=buy | ||

|matspec=20A three-pole connector | |matspec=20A three-pole connector | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=3.04 | |matpartnumber=3.04 | ||

| Line 627: | Line 724: | ||

|matspec=Premixed polyester resin with accelerator | |matspec=Premixed polyester resin with accelerator | ||

|matpdffile=oho_tdc2_3.04_Casting del rotor.pdf | |matpdffile=oho_tdc2_3.04_Casting del rotor.pdf | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}}{{ProjektMaterials | }}{{ProjektMaterials | ||

|matpartnumber=3.05 | |matpartnumber=3.05 | ||

| Line 633: | Line 732: | ||

|matparttype=buy | |matparttype=buy | ||

|matspec=Ferrite magnet block, grade 3, pre magnetized, 30*46*10mm | |matspec=Ferrite magnet block, grade 3, pre magnetized, 30*46*10mm | ||

|status_rev_1=approved | |||

|status_rev_2=approved | |||

}} | }} | ||

|certificate_requested=No | |certificate_requested=No | ||

|certificate_status=approved | |||

|reviewer1=Xtech2020_review | |||

|reviewer2=Thehunter | |||

}} | }} | ||

Latest revision as of 14:17, 6 April 2023

|

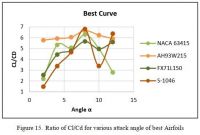

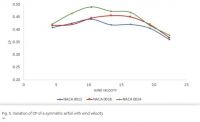

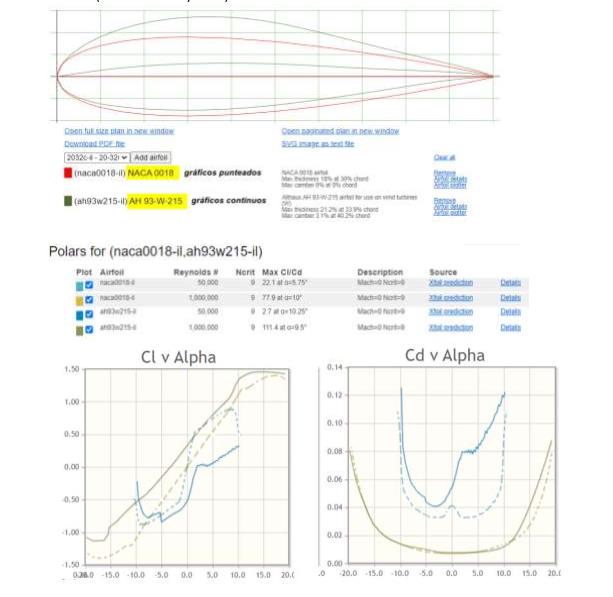

Darrieus Turbine - 2m combined Basic Data Category: Wind turbines URL (first publication): https://youtube.com/shorts/Alf6EOTmlHM?feature=share Keywords: wind turbine, vertical, vawt, blades, piggott, alternator, efficiency, lattice tower, airfoil, AH93W215, savonius, auto start License: CC BY-SA 4.0 Organization: OHO Project status: Active Certification status: Approved Technical documentation Maturity of the project: prototype

Contains PDF-drawings: Yes CAD files are editable: Yes Assembly instructions are published: Yes Bill of materials is published: Yes

yes yes

|

|

Description

Technical documentation

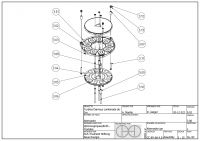

PDF plans | |

|

|

Files: | |

CAD files | |

|

|

Files: | |

Technical development | |

|

|

Files: | |

Project development | |

Based on the DIN 2221 standard, among others, OHO has established a series of stages in which the satisfactory completion of this project was carried out

1 Feasibility studyManufacturing as OSAT technology is possible?

2 Market analisis and requirements Functional and quantitative requirementsFunctional and quantitative requirements

3 Search & analisis DIY technologiesThe best technical solutions for all parts and components

4 Development and documentationPlans and specifications of all parts and components

5. Manufacturing, tests and improvementsTo date, this project is on hold for manufacturing

The purchasing, prototype manufacturing, testing, and documentation updating sub-processes, will be developed once the manufacturing stage is completed 6. Certification DIN Spec 3105

The project was reviewed by two reviewers from the OHO team. The review consisted of the following components:

Detail abot the review process: https://en.oho.wiki/wiki/Instructions_for_Reviewers Permanent Link: https://en.oho.wiki/index.php?title=Darrieus_Turbine_-_2m_combined&oldid=45791 | |

+ General Reviews

Parts list

| Pos. | Qty. | Part Name | Part code | Part Type | Specifications | Review Status | Show All Comments | |

|---|---|---|---|---|---|---|---|---|

| A1 | 1 | 3D Views |

REV1: Approved |

|||||

| A2 | 1 | 3D Explosion Views |

REV1: Approved |

|||||

| B | Parts list |

REV1: Approved |

||||||

| C | Technical notes |

REV1: Approved |

||||||

| 1.00 | 1 | Blade assembly |

REV1: Approved |

|||||

| 1.01 | 18 | Rib | Production | Cedar or pine wood, 350*74*12mm |

REV1: Approved |

|||

| 1.02 | 3 | Rib2 | Production | Cedar or pine wood, 500*500*500*12mm |

REV1: Approved |

|||

| 1.03 | 3 | Fiber layer1 | Production | Fiberglass and polyester resin, optional polyurethane filling. thickness: 3-5 mm |

REV1: Approved |

|||

| 1.04 | 3 | Fiber layer2 | Production | Fiberglass and polyester resin, optional polyurethane filler. thickness: 3-5 mm |

REV1: Approved |

|||

| 1.05 | 3 | Fiber layer3 | Production | Fiberglass and polyester resin, optional polyurethane filler. thickness: 3-5 mm. |

REV1: Approved |

|||

| 1.06 | 6 | Blade reinforcement1 | Production | Round tube 3/8", sch40 or similar, aluminum. |

REV1: Approved |

|||

| 1.07 | 2 | Bearing | Buy | SKF 61808 2RZ bearing, 40*52*7mm, with double seal, double stuffing box HM4R and flanged housing |

REV1: Approved |

|||

| 1.08 | 3 | Blade arm1 | Production | Round tube 1 1/4", sch40 or similar, Iron |

REV1: Approved |

|||

| 1.09 | 3 | Blade support1 | Production | Plate 1 1/2"*4mm*117mm |

REV1: Approved |

|||

| 1.10 | 3 | Blade bracket21 | Production | Plate 1 1/2"*4mm*190mm |

REV1: Approved |

|||

| 1.11 | 6 | Blade bolt2 | Standard | Hexagonal bolt 3/8*2 1/2", UNC, grade5 |

REV1: Approved |

|||

| 1.12 | 6 | Blade nut2 | Standard | Hex nut 3/8", UNC, grade 5 |

REV1: Approved |

|||

| 1.13 | 6 | Blade washer2 | Standard | Flat washer for 3/8 |

REV1: Approved |

|||

| 1.14 | 18 | Blade bolt1 | Standard | Hexagonal bolt 1/4*4*1" UNC, grade 5 |

REV1: Approved |

|||

| 1.15 | 18 | Blade nut1 | Standard | Hex Nut, 1/4", UNC, Grade 5 |

REV1: Approved |

|||

| 1.16 | 18 | Washer washer washer1 | Standard | Flat washer for 1/4 |

REV1: Approved |

|||

| 1.17 | 63 | Blade reinforcement bolt1 | Standard | Drywall screw 1 1/2"#8 |

REV1: Approved |

|||

| 1.18 | 9 | Blade band | Production | Plate 1*1/8"*340mm |

REV1: Approved |

|||

| 2.00 | 1 | Tower structure |

REV1: Approved |

|||||

| 2.01 | 4 | Main prop | Production | Angle 1*1"*3mm*2422mm |

REV1: Approved |

|||

| 2.02 | 4 | Cross member1 | Production | Angle 1*1"*3mm*616mm |

REV1: Approved |

|||

| 2.03 | 4 | Crossbeam2 | Production | Angle 1*1"*3mm*425mm |

REV1: Approved |

|||

| 2.04 | 4 | Crossbeam3 | Production | Angle 1*1"*3mm*233mm |

REV1: Approved |

|||

| 2.05 | 4 | Truss1 | Production | Round iron bar D3/8"*1100mm |

REV1: Approved |

|||

| 2.06 | 4 | Truss2 | Production | Round iron bar D3/8"*1030mm |

REV1: Approved |

|||

| 2.07 | 4 | Anchor eye | Production | Flat bar 1 1/2"* 4mm*60mm |

REV1: Approved |

|||

| 2.08 | 1 | Central post | Production | Round iron pipe 1 1/4" sch40 (e 3.5mm)*2100mm, Cylindrical |

REV1: Approved |

|||

| 2.09 | 1 | Post guide | Production | Round iron pipe 1 1/2", sch40 (e 3.7mm) or similar, l 500mm |

REV1: Approved |

|||

| 2.10 | 8 | Post support | Production | Plate 1 1/2"*4mm*177mm |

REV1: Approved |

|||

| 2.11 | 1 | Stator support | Production | Iron plate 450*450*5mm |

REV1: Approved |

|||

| 2.12 | 2 | Post bolt | Standard | Hexagonal bolt 3/8*2 1/2" UNC, grade 5 |

REV1: Approved |

|||

| 2.13 | 2 | Post nut | Standard | Hexagonal nut 3/8" UNC, grade 5 |

REV1: Approved |

|||

| 3.00 | 1 | Alternator |

REV1: Approved |

|||||

| 3.01 | 1 | Stator Casting | Production | Pre-mixed polyester resin with accelerator |

REV1: Approved |

|||

| 3.02 | 9 | Coil | Production | Enameled copper cable, D 1.7 mm, 73 turns (for 12V), total weight: 3 kg |

REV1: Approved |

|||

| 3.03 | 1 | Connector1 | Buy | 20A three-pole connector |

REV1: Approved |

|||

| 3.04 | 2 | Rotor casting | Production | Premixed polyester resin with accelerator |

REV1: Approved |

|||

| 3.05 | 24 | Ferrite magnet | Buy | Ferrite magnet block, grade 3, pre magnetized, 30*46*10mm |

REV1: Approved |

|||