Difference between revisions of "Darrieus Turbine - 2m combined"

From OHO - search engine for sustainable open hardware projects

Inddigital (talk | contribs) ((by SublimeText.Mediawiker)) |

Inddigital (talk | contribs) ((by SublimeText.Mediawiker)) |

||

| Line 98: | Line 98: | ||

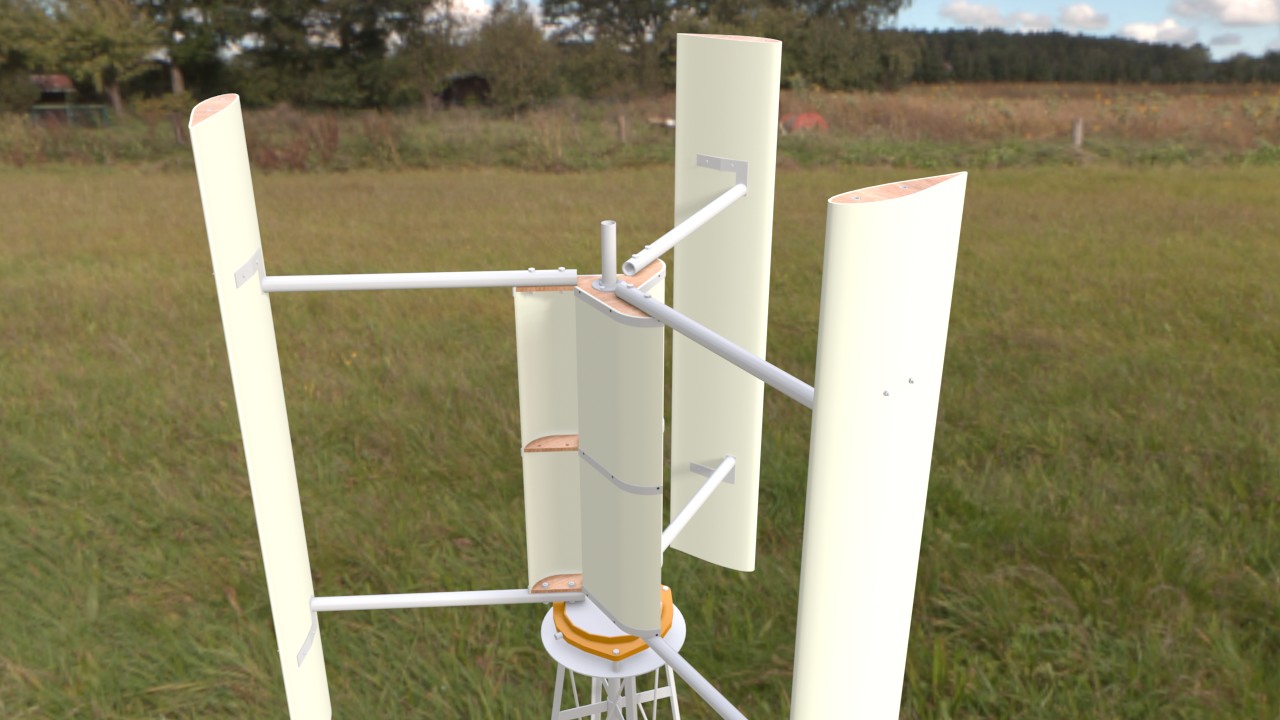

[[File:Oho_teh2_W9KErFi.jpeg|300px|thumb]] | [[File:Oho_teh2_W9KErFi.jpeg|300px|thumb]] | ||

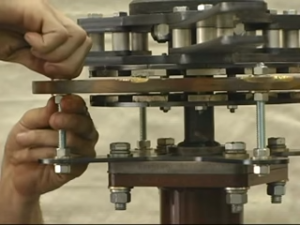

:: Even in the manufacture of the generator, the tasks can be carried out by personnel with general training in workshop processes | :: Even in the manufacture of the generator, the tasks can be carried out by personnel with general training in workshop processes | ||

<div style="margin: | <div style="margin:180px"></div> | ||

[[File:Oho_tdc2_wMM2m5Lkslw.jpg|300px|thumb]] | |||

* Specific training | * Specific training | ||

:: Is specific training for manufacturing necessary and can be provided? | :: Is specific training for manufacturing necessary and can be provided? | ||

:: ✗ No | :: ✗ No | ||

Revision as of 15:58, 24 January 2023

|

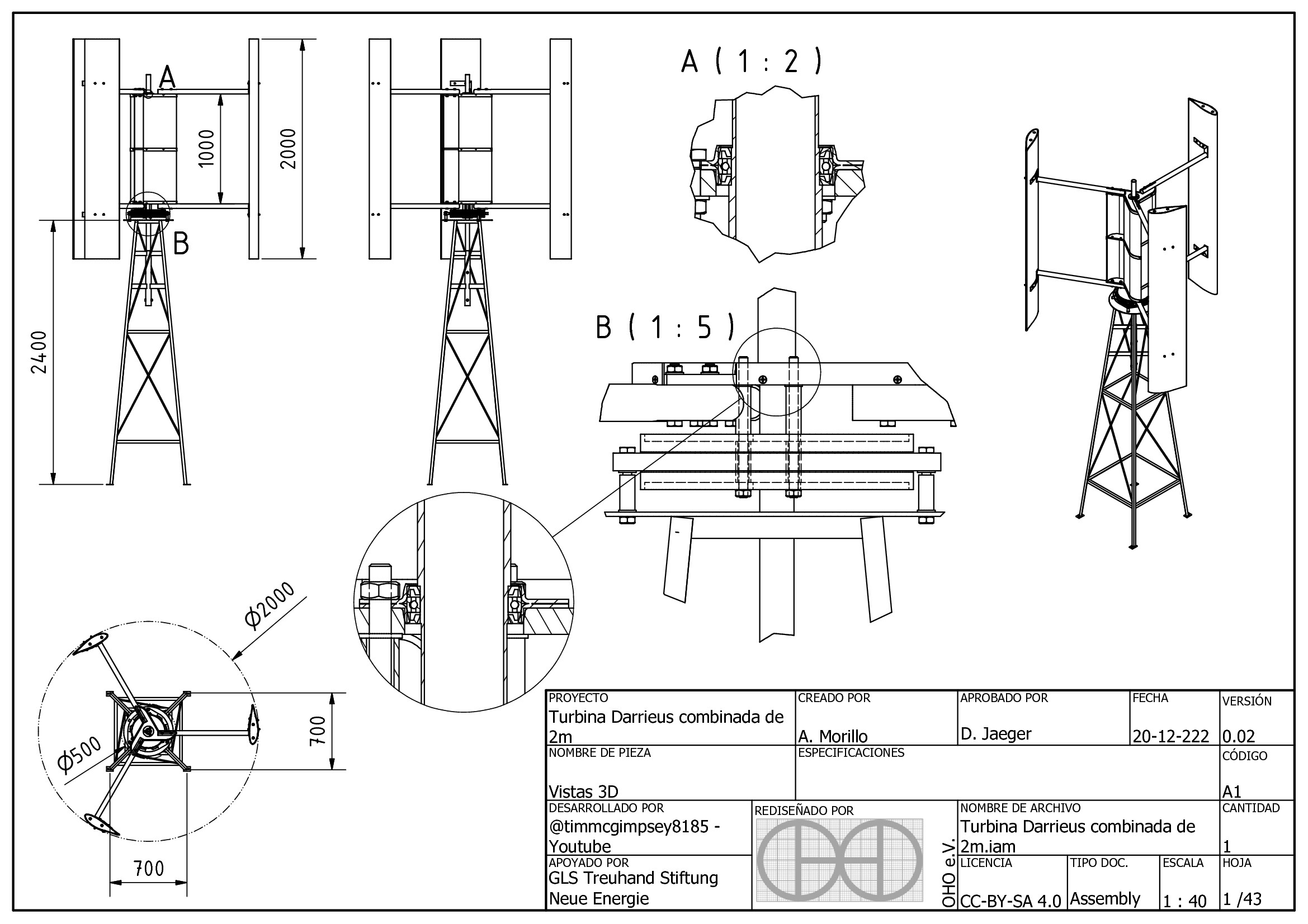

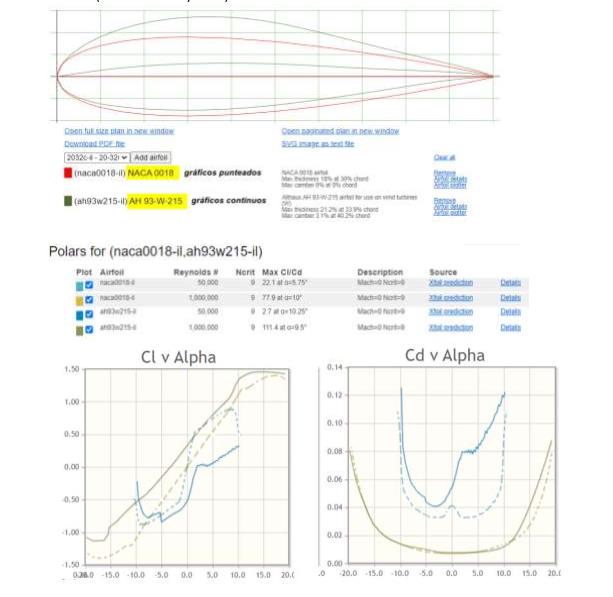

Darrieus Turbine - 2m combined Basic Data Category: Wind turbines URL (first publication): https://youtube.com/shorts/Alf6EOTmlHM?feature=share Keywords: wind turbine, vertical, vawt, blades, piggott, alternator, efficiency, lattice tower, airfoil, AH93W215, savonius, auto start License: CC BY-SA 4.0 Organization: OHO Project status: Active

Technical documentation Maturity of the project: prototype

Contains PDF-drawings: Yes CAD files are editable: Yes Assembly instructions are published: Yes Bill of materials is published: Yes

yes yes

|

|

Description

Technical documentation

PDF plans | |

|

|

Files: | |

CAD files | |

|

|

Files: | |

Technical development | |

|

|

Files: | |

Project development | |

Based on the DIN 2221 standard, among others, OHO has established a series of stages in which the satisfactory completion of this project was carried out

1 Feasibility studyManufacturing as OSAT technology is possible?

| |

+ General Reviews

Parts list

| Pos. | Qty. | Part Name | Part code | Part Type | Specifications | Review Status | Show All Comments | |

|---|---|---|---|---|---|---|---|---|

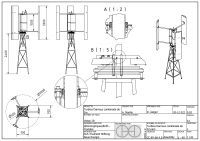

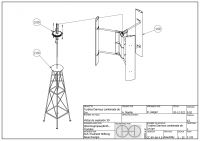

| A1 | 1 | 3D Views | ||||||

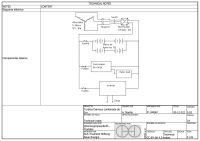

| A2 | 1 | 3D Explosion Views | ||||||

| B | Parts list | |||||||

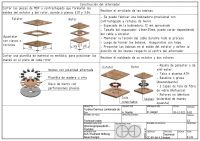

| C | Technical notes | |||||||

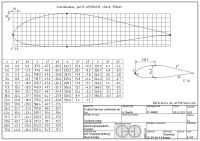

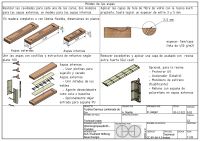

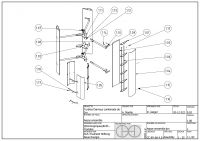

| 1.00 | 1 | Blade assembly | ||||||

| 1.01 | 18 | Rib | Production | Cedar or pine wood, 350*74*12mm | ||||

| 1.02 | 3 | Rib2 | Production | Cedar or pine wood, 500*500*500*12mm | ||||

| 1.03 | 3 | Fiber layer1 | Production | Fiberglass and polyester resin, optional polyurethane filling. thickness: 3-5 mm | ||||

| 1.04 | 3 | Fiber layer2 | Production | Fiberglass and polyester resin, optional polyurethane filler. thickness: 3-5 mm | ||||

| 1.05 | 3 | Fiber layer3 | Production | Fiberglass and polyester resin, optional polyurethane filler. thickness: 3-5 mm. | ||||

| 1.06 | 6 | Blade reinforcement1 | Production | Round tube 3/8", sch40 or similar, aluminum. | ||||

| 1.07 | 2 | Bearing | Buy | SKF 61808 2RZ bearing, 40*52*7mm, with double seal, double stuffing box HM4R and flanged housing | ||||

| 1.08 | 3 | Blade arm1 | Production | Round tube 1 1/4", sch40 or similar, Iron | ||||

| 1.09 | 3 | Blade support1 | Production | Plate 1 1/2"*4mm*117mm | ||||

| 1.10 | 3 | Blade bracket21 | Production | Plate 1 1/2"*4mm*190mm | ||||

| 1.11 | 6 | Blade bolt2 | Standard | Hexagonal bolt 3/8*2 1/2", UNC, grade5 | ||||

| 1.12 | 6 | Blade nut2 | Standard | Hex nut 3/8", UNC, grade 5 | ||||

| 1.13 | 6 | Blade washer2 | Standard | Flat washer for 3/8 | ||||

| 1.14 | 18 | Blade bolt1 | Standard | Hexagonal bolt 1/4*4*1" UNC, grade 5 | ||||

| 1.15 | 18 | Blade nut1 | Standard | Hex Nut, 1/4", UNC, Grade 5 | ||||

| 1.16 | 18 | Washer washer washer1 | Standard | Flat washer for 1/4 | ||||

| 1.17 | 63 | Blade reinforcement bolt1 | Standard | Drywall screw 1 1/2"#8 | ||||

| 1.18 | 9 | Blade band | Production | Plate 1*1/8"*340mm | ||||

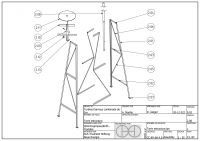

| 2.00 | 1 | Tower structure | ||||||

| 2.01 | 4 | Main prop | Production | Angle 1*1"*3mm*2422mm | ||||

| 2.02 | 4 | Cross member1 | Production | Angle 1*1"*3mm*616mm | ||||

| 2.03 | 4 | Crossbeam2 | Production | Angle 1*1"*3mm*425mm | ||||

| 2.04 | 4 | Crossbeam3 | Production | Angle 1*1"*3mm*233mm | ||||

| 2.05 | 4 | Truss1 | Production | Round iron bar D3/8"*1100mm | ||||

| 2.06 | 4 | Truss2 | Production | Round iron bar D3/8"*1030mm | ||||

| 2.07 | 4 | Anchor eye | Production | Flat bar 1 1/2"* 4mm*60mm | ||||

| 2.08 | 1 | Central post | Production | Round iron pipe 1 1/4" sch40 (e 3.5mm)*2100mm, Cylindrical | ||||

| 2.09 | 1 | Post guide | Production | Round iron pipe 1 1/2", sch40 (e 3.7mm) or similar, l 500mm | ||||

| 2.10 | 8 | Post support | Production | Plate 1 1/2"*4mm*177mm | ||||

| 2.11 | 1 | Stator support | Production | Iron plate 450*450*5mm | ||||

| 2.12 | 2 | Post bolt | Standard | Hexagonal bolt 3/8*2 1/2" UNC, grade 5 | ||||

| 2.13 | 2 | Post nut | Standard | Hexagonal nut 3/8" UNC, grade 5 | ||||

| 3.00 | 1 | Alternator | ||||||

| 3.01 | 1 | Stator Casting | Production | Pre-mixed polyester resin with accelerator | ||||

| 3.02 | 9 | Coil | Production | Enameled copper cable, D 1.7 mm, 73 turns (for 12V), total weight: 3 kg | ||||

| 3.03 | 1 | Connector1 | Buy | 20A three-pole connector | ||||

| 3.04 | 2 | Rotor casting | Production | Premixed polyester resin with accelerator | ||||

| 3.05 | 24 | Ferrite magnet | Buy | Ferrite magnet block, grade 3, pre magnetized, 30*46*10mm | ||||