Angle grinder stand

Project data

|

Category: Angle grinders URL (first publication): https://www.youtube.com/watch?v=l8SEEqtCDrc Keywords: grinder, angle, stand, diy, metal, machine, workshop, open source, cutting, disc License: CC BY-SA 4.0 Organization: OHO Project status: Active

Maturity of the project: prototype

Contains PDF-drawings: Yes CAD files are editable: Yes Assembly instructions are published: Yes Bill of materials is published: Yes

yes yes

|

Project details

Description

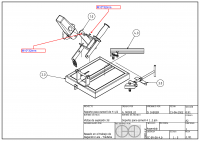

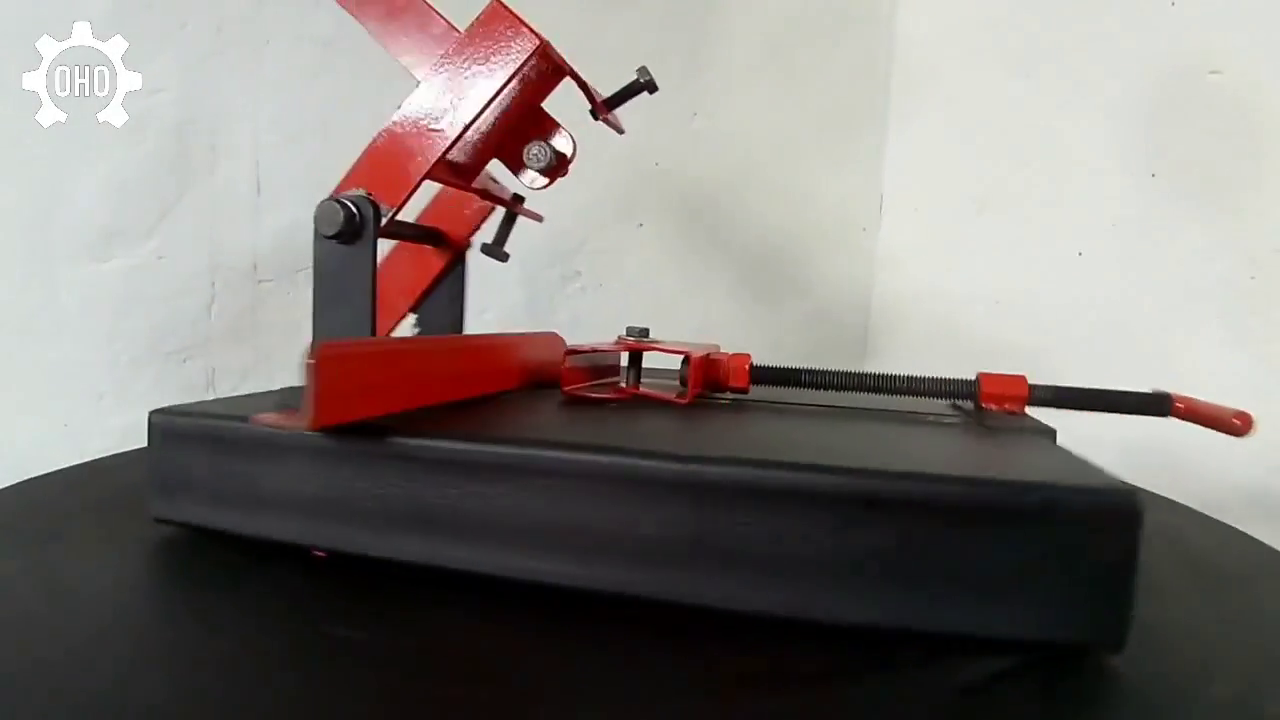

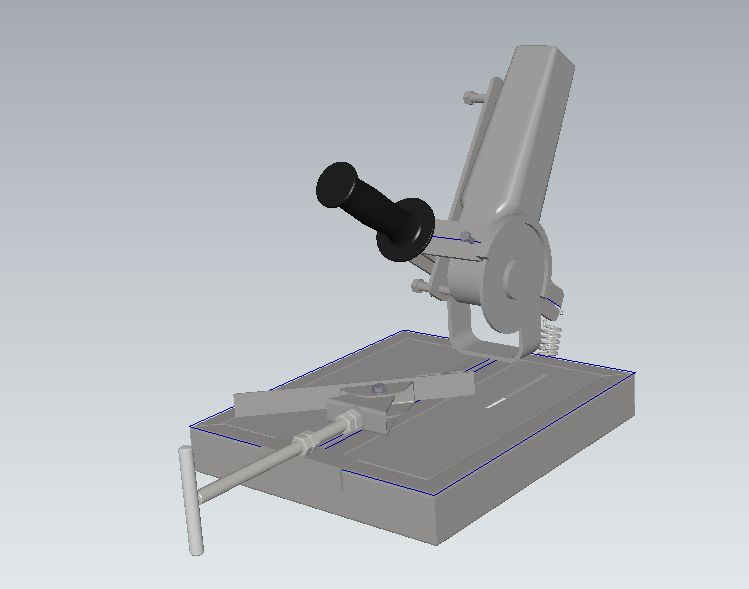

Within the line of devices and tools for the workshop, we present the Angle Grinder Support. This was designed and manufactured by our our technical team, based on the work of Alejandro Luis on YouTube. The OHO Angle Grinder Support is thought to provide a stable platform for the angle grinder during its operation.

It features a sturdy construction with an anchorable base to ensure stability and prevent slipping. The support also has an adjustable arm that can be adjusted to fit any size angle grinder, allowing to work with ease and confidence. With its easy-to-use design and reliable construction, the Angle Grinder Support is the perfect tool for any DIYer or professional looking for an efficient way to get their job done.

Project developer

This project has been analyzed and redesigned by the OHO technical team, based on an extensive review of similar technical solutions, planned by various entrepreneurs and enthusiasts, taking the work of developer Alejandro Luis, from YouTube, as the main reference.

Project objectives

Among some of the objectives set in the realization of this project, we can mention:

- Make workshop devices of great practical utility

- Improve methodologies for the development of Open Source projects

- Manage project certification according to the guidelines established by OHO

- Contribute to the promotion and development of Appropriate Technologies

Target groups

This project is mainly aimed at people and small businesses that work with metals in the production of non-industrialized goods, oriented towards community development and sustainable production, among these we can mention:

- Small workshops

- Small and medium businesses

- Individuals from the metalworking and blacksmithing sector

- Non-governmental educational entities

Achievements, promotion

The product will be offered to the community near its manufacture, to give continuity to the process of evaluation and continuous improvement.

To date, this device has been used for the manufacture of other equipment, showing excellent performance.

Sustainable development goals

The design and manufacture of a DIY angle grinder stand can contribute to several of the United Nations' Sustainable Development Goals, including:

- Goal 9: Industry, Innovation, and Infrastructure: Innovation in industry and infrastructure is being fostered, and the use of safer and more efficient tools and techniques for workers is being promoted.

- Goal 12: Responsible Production and Consumption: More sustainable materials and processes can be used, which can reduce the environmental impact of production and consumption. It can also promote the maintenance and repair of existing tools, rather than discarding and replacing them.

- Goal 8: Decent Work and Economic Growth: The manufacture of the stand can create employment opportunities and promote local economic growth, especially if local materials and resources are used.

- Goal 3: Good Health and Well-being: The use of the angle grinder stand can improve the safety and health of workers by reducing the risk of injuries and occupational accidents.

- Goal 11: Sustainable Cities and Communities: The creation and use of the angle grinder stand can improve working conditions in local communities by providing safer and more efficient tools for workers. Additionally, the manufacture of the stand can foster the creation of a local circular economy and reduce the need to import manufactured goods from other regions.

Note: This project was supported by the german Foundation E.ON Stiftung.

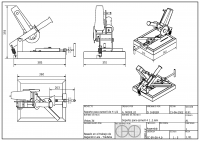

Technical data

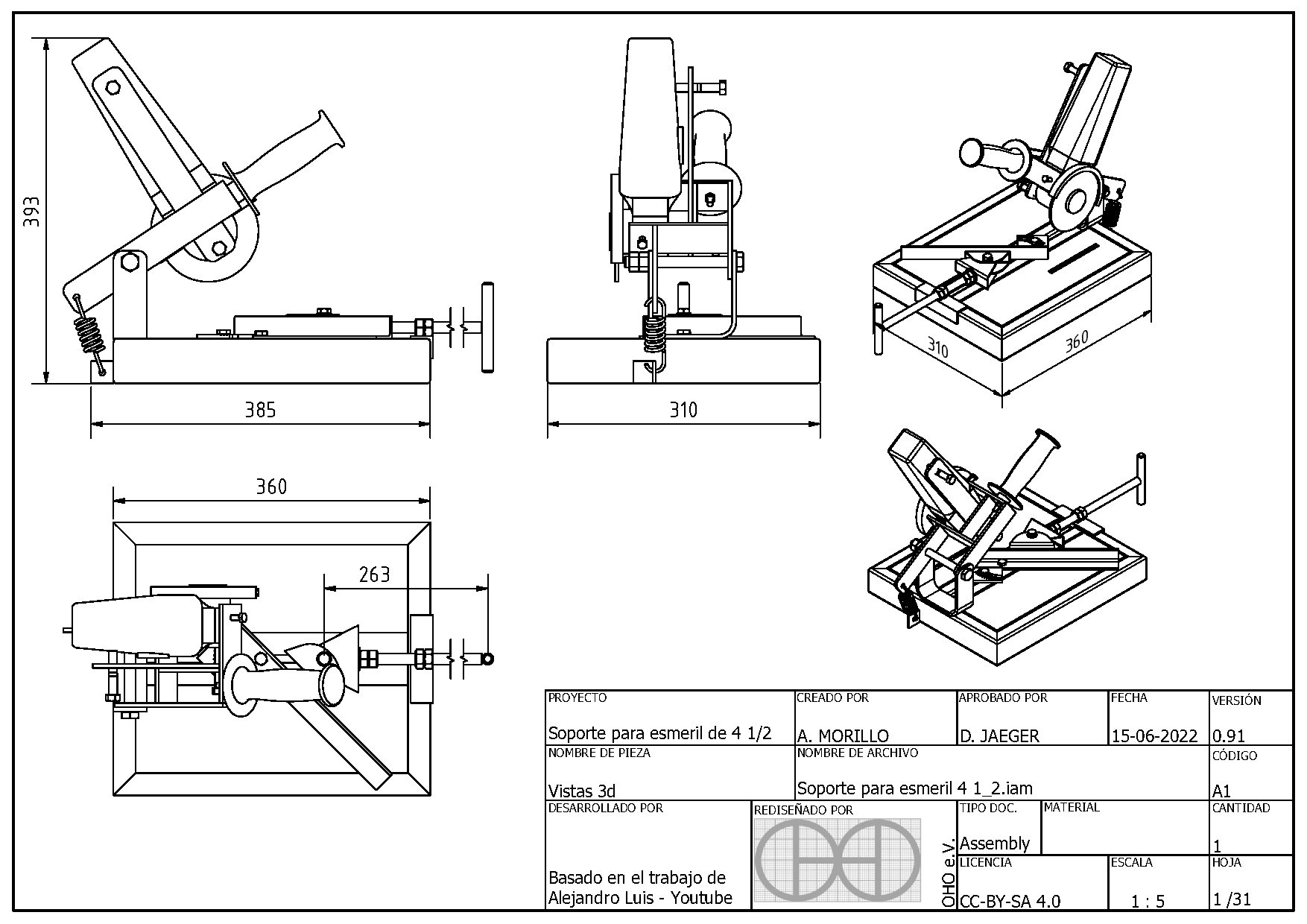

| Request | Detail |

|---|---|

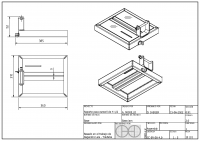

| Base size [mm] | 360x310 |

| Preferred grinder size | 4-1/2" |

| Cutting angle [°] | 0 - 45 |

| Press arm [mm] | 250 |

Additional features

| Detail evaluated | Variants |

|---|---|

| Fastening to device | Double screw in hull plus stops |

| Equipment alignment | Direct articulation with bolt |

| Retraction mechanism | Traction spring on arm extension |

| Drive | Equipment's own handle fixed to the arm side |

| Anchorage | Optional ears for anchoring |

| Disc protection cover | Own equipment |

| Base structure construction | Tube or angle frame |

| Part clamping and tilting mechanism | Press with adjustable angle stop |

| Degrees of freedom of movement of the grinding wheel | Rotation only |

Technical documentation

| |

|

|

Files: | |

| |

|

|

Files: | |

| |

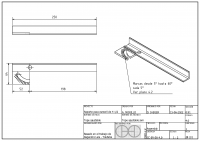

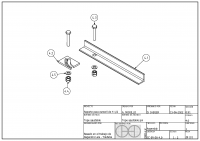

| Here are some plans with the assembly sets and pieces, which can be detailed at this link | |

Tests, practical applications

| Type of test | Detail | Description | Status |

|---|---|---|---|

| Initial preparation | Anchoring | Securely anchor the equipment with clamps | - |

| Grinder installation | Install the equipment in the clamp | - | |

| Sample part | Cut an angle of 1 /4"*40 cm | - | |

| Preparation | |||

| Adjustments on assemblies (no load test) | Clamping of the angle grinder | Keep the handle of the equipment immobilized. | ✓ Done |

| Apply moderate force on the grinding wheel, from side to side and from top to bottom. | |||

| Press grip | Mount and tighten the sample firmly in the press at 90°. | ✓ Done | |

| Attempt to remove the sample by hand, applying moderate force. | |||

| Cut | Main test | Cutting only the edge of the sample (reflowing) | ✓ Done |

| Loosen the press and adjust to 45°(check that the work piece is aligned with the cutting area). | |||

| Make a 45° cut | |||

| Accuracy of the result | Measurement of cuts | Remove the sample, to detail: | ✓ Done |

| Appearance of the cut | |||

| Accuracy of cutting angles |

+ General Reviews

Reviews

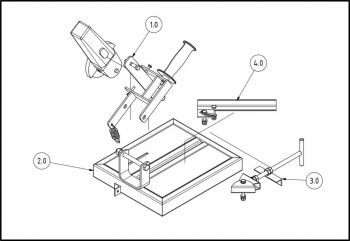

| Pos. | Qty. | Part Name | Part code | Part Type | Specifications | Review Status | Show All Comments | |

|---|---|---|---|---|---|---|---|---|

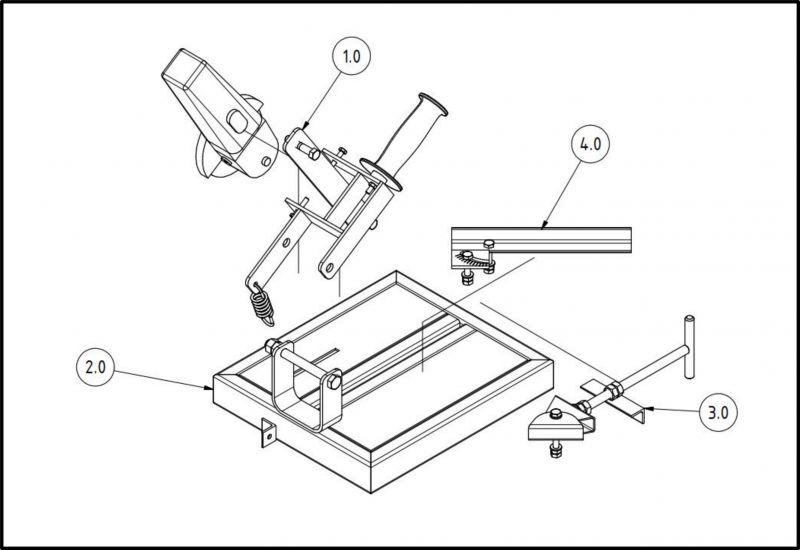

| A1 | 1 | 3D views | ||||||

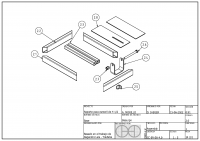

| A2 | 1 | Exploded 3D views | ||||||

| B | Parts list | |||||||

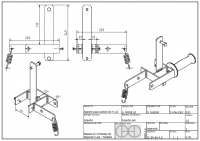

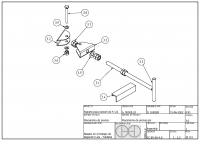

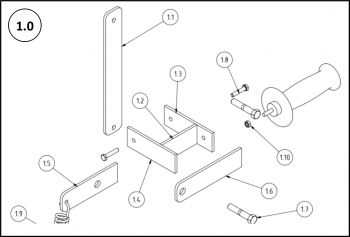

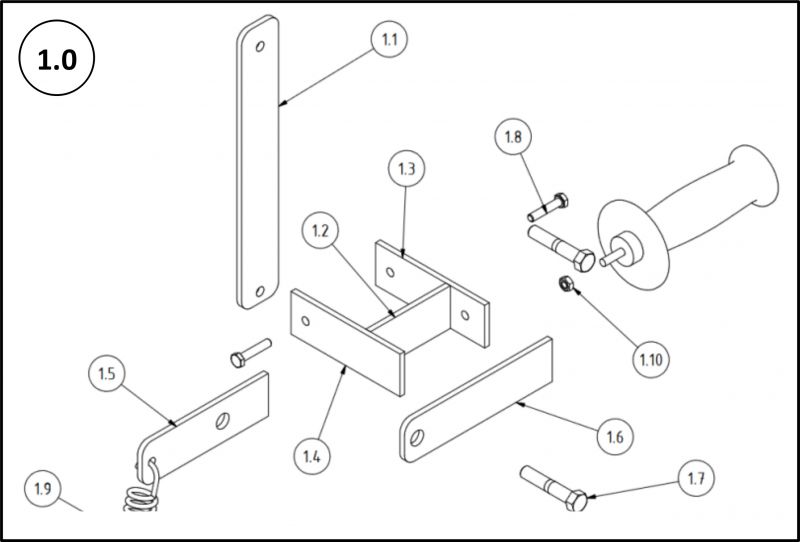

| 1.0 | 1 | Support | ||||||

| 1.1 | 1 | Seat | Production | Plate 1 1/2*3/16", A36 Steel | ||||

| 1.2 | 1 | Crossbar | Production | Plate 1 1/2*3/16", A36 Steel | ||||

| 1.3 | 1 | Side1 | Production | Plate 1 1/2*3/16", A36 Steel | ||||

| 1.4 | 1 | Side2 | Production | Plate 1 1/2*3/16", Stainless Steel A36 | ||||

| 1.5 | 1 | Extension1 | Production | Plate 1 1/2*3/16", Stainless Steel A36 | ||||

| 1.6 | 1 | Extension2 | Production | Plate 1 1/2*3/16", Steel A36 | ||||

| 1.7 | 2 | Rear stop | Standard | Hexagonal screw 3/8*2", Steel A36 | ||||

| 1.8 | 2 | Retaining screw | Standard | Hexagonal bolt 1/4*1". | ||||

| 1.9 | 1 | Retraction spring | Buy | Tension spring L: 90 mm, F 20 kg, D: 23mm | ||||

| 1.10 | 1 | Nut for handle | Standard | Hex nut 1/4", optional | ||||

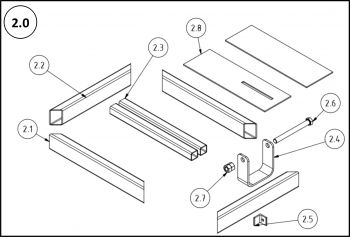

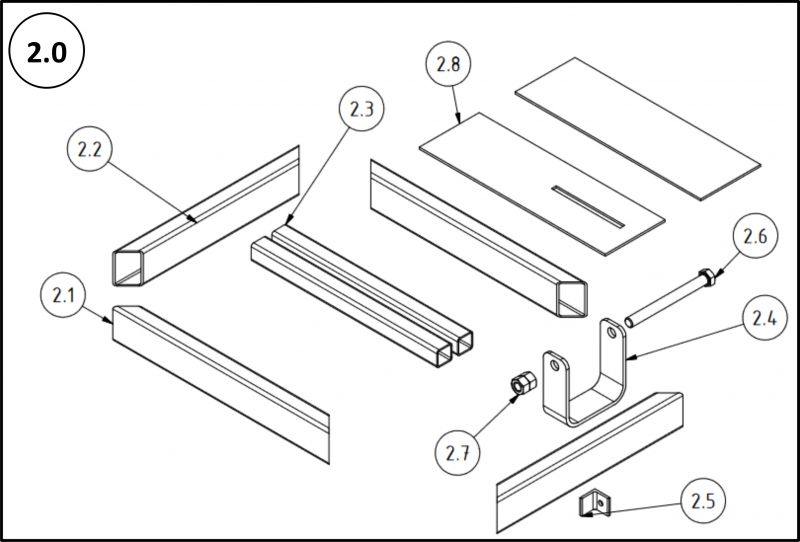

| 2.0 | 1 | Base | ||||||

| 2.1 | 2 | Base frame1 | Production | 2*1" rectangular tube 14 gauge, A36 Steel | ||||

| 2.2 | 2 | Base frame2 | Production | Rectangular tube 2*1" 14 gauge, A36 Steel | ||||

| 2.3 | 2 | Guide base | Production | 1*1" 14-gauge rectangular tubing, A36 steel | ||||

| 2.4 | 1 | Fork1 | Production | Plate 1 1/2*3/16", A36 Steel | ||||

| 2.5 | 1 | Spring lug | Production | Angle 2*2*1/8", A36 Steel | ||||

| 2.6 | 1 | Articulation screw | Standard | Hex bolt 1/2*5", A36 Steel | ||||

| 2.7 | 2 | Articulation nut | Standard | Hex Nut 1/2 | ||||

| 2.8 | 2 | Base plate | Production | Sheet 3mm, Steel C45 | ||||

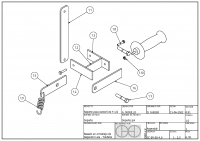

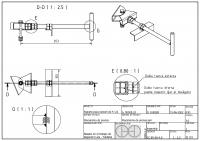

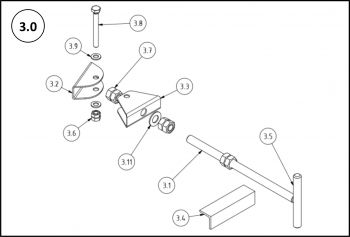

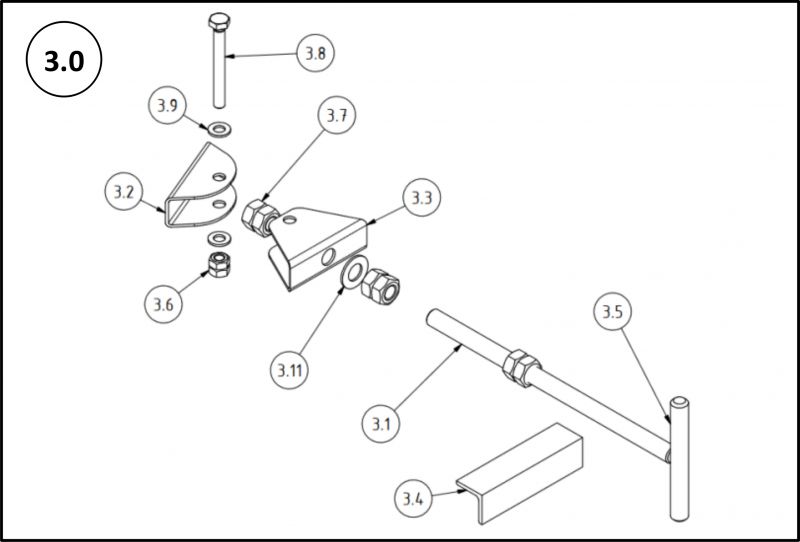

| 3.0 | 1 | Press mechanism | ||||||

| 3.1 | 1 | Power screw | Production | Threaded rod 1/2", A36 Steel | ||||

| 3.2 | 1 | Vice | Production | Rectangular pipe 2*1" 14 gauge, A36 Steel | ||||

| 3.3 | 1 | Vice holder | Production | 2*1" 14-gauge rectangular pipe, A36 Steel | ||||

| 3.4 | 1 | Press support | Production | Angle 1*1*1*-1/8", A36 Steel | ||||

| 3.5 | 1 | Handle | Production | 1/2" round bar, A36 Steel | ||||

| 3.6 | 4 | Stop nut | Standard | Hex Nut 5/16" Hex Nut | ||||

| 3.7 | 4 | Power nut | Standard | Hex Nut 1/2" Hex Nut | ||||

| 3.8 | 1 | Vise bolt | Standard | 5/16*3" Hex Bolt | ||||

| 3.9 | 2 | Jaw washer | Standard | Washer 3/8 | ||||

| 3.11 | 1 | Power Washer | Standard | Washer 1/2" Washer | ||||

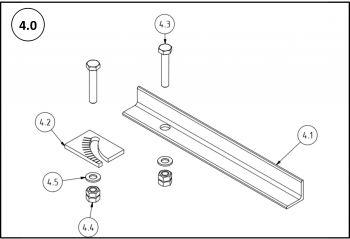

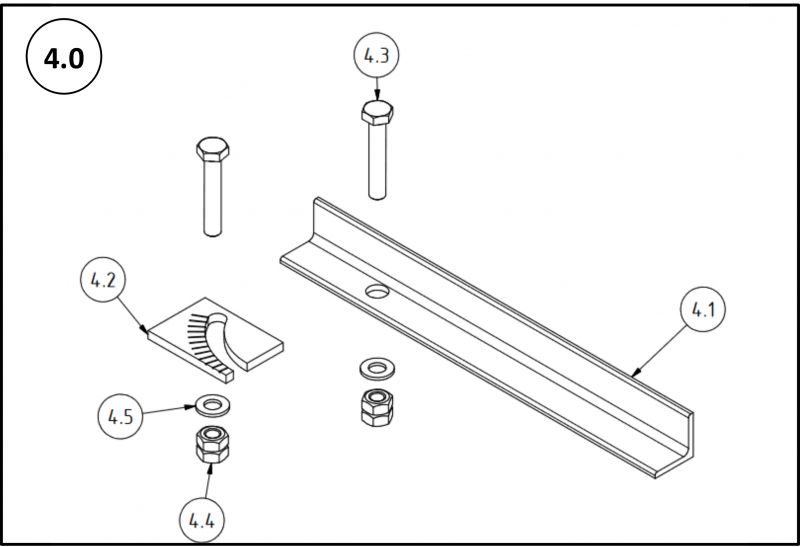

| 4.0 | 1 | Adjustable stop | ||||||

| 4.1 | 1 | Stop | Production | Angle 1*1*1/8", Steel A36 | ||||

| 4.2 | 1 | Stop pivot guide | Production | Plate 1 1/2*3/16, Steel A36 | ||||

| 4.3 | 2 | Press screw | Standard | Hexagonal Screw 5/16*2 | ||||

| 4.4 | 4 | Press nut | Standard | Hex Nut 5/16" Hex Nut | ||||

| 4.5 | 2 | Press washer | Standard | Washer 3/8" | ||||