Difference between revisions of "Angle grinder stand"

From OHO - search engine for sustainable open hardware projects

Inddigital (talk | contribs) ((by SublimeText.Mediawiker)) |

Inddigital (talk | contribs) ((by SublimeText.Mediawiker)) |

||

| Line 111: | Line 111: | ||

|cmpimg= | |cmpimg= | ||

<div width="100%"> | <div width="100%"> | ||

<table width="50%" style="border: solid;"> | <table width="50%" style="border: solid 1px !important;"> | ||

<tr style="visibility: collapse;"> | <tr style="visibility: collapse;"> | ||

<td width='50%'></td> | <td width='50%'></td> | ||

<td width='50%'></td> | <td width='50%'></td> | ||

</tr> | </tr> | ||

<tr style="border: solid;"> | <tr style="border: solid 1px !important;"> | ||

<th> Request | <th> Request | ||

</th> | </th> | ||

| Line 148: | Line 148: | ||

|cmpimg= | |cmpimg= | ||

<div width="100%"> | <div width="100%"> | ||

<table width="50%" style="border: solid;"> | <table width="50%" style="border: solid 1px !important;"> | ||

<tr style="visibility: collapse;"> | <tr style="visibility: collapse;"> | ||

<td width='50%'></td> | <td width='50%'></td> | ||

| Line 157: | Line 157: | ||

<th>Variants</th> | <th>Variants</th> | ||

</tr> | </tr> | ||

<tr style="border: solid;"> | <tr style="border: solid 1px !important;"> | ||

<td>Fastening to device</td> | <td>Fastening to device</td> | ||

<td>Double screw in hull plus stops</td> | <td>Double screw in hull plus stops</td> | ||

</tr> | </tr> | ||

<tr style="border: solid;"> | <tr style="border: solid 1px !important;"> | ||

<td>Equipment alignment</td> | <td>Equipment alignment</td> | ||

<td>Direct articulation with bolt</td> | <td>Direct articulation with bolt</td> | ||

</tr> | </tr> | ||

<tr style="border: solid;"> | <tr style="border: solid 1px !important;"> | ||

<td>Retraction mechanism</td> | <td>Retraction mechanism</td> | ||

<td>Traction spring on arm extension</td> | <td>Traction spring on arm extension</td> | ||

</tr> | </tr> | ||

<tr style="border: solid;"> | <tr style="border: solid 1px !important;"> | ||

<td>Drive</td> | <td>Drive</td> | ||

<td>Equipment's own handle fixed to the arm side</td> | <td>Equipment's own handle fixed to the arm side</td> | ||

</tr> | </tr> | ||

<tr style="border: solid;"> | <tr style="border: solid 1px !important;"> | ||

<td>Anchorage</td> | <td>Anchorage</td> | ||

<td>Optional ears for anchoring</td> | <td>Optional ears for anchoring</td> | ||

</tr> | </tr> | ||

<tr style="border: solid;"> | <tr style="border: solid 1px !important;"> | ||

<td>Disc protection cover</td> | <td>Disc protection cover</td> | ||

<td>Own equipment</td> | <td>Own equipment</td> | ||

</tr> | </tr> | ||

<tr style="border: solid;"> | <tr style="border: solid 1px !important;"> | ||

<td>Base structure construction</td> | <td>Base structure construction</td> | ||

<td>Tube or angle frame</td> | <td>Tube or angle frame</td> | ||

</tr> | </tr> | ||

<tr style="border: solid;"> | <tr style="border: solid 1px !important;"> | ||

<td>Part clamping and tilting mechanism</td> | <td>Part clamping and tilting mechanism</td> | ||

<td>Press with adjustable angle stop</td> | <td>Press with adjustable angle stop</td> | ||

</tr> | </tr> | ||

<tr style="border: solid;"> | <tr style="border: solid 1px !important;"> | ||

<td>Degrees of freedom of movement of the grinding wheel</td> | <td>Degrees of freedom of movement of the grinding wheel</td> | ||

<td>Rotation only</td> | <td>Rotation only</td> | ||

| Line 211: | Line 211: | ||

|cmpimg= | |cmpimg= | ||

<div width="100%"> | <div width="100%"> | ||

<table border = "1" width="100%" style="border: solid;"> | <table border = "1" width="100%" style="border: solid 1px !important;"> | ||

<tr style="visibility: collapse;"> | <tr style="visibility: collapse;"> | ||

<td width='20%'></td> | <td width='20%'></td> | ||

| Line 218: | Line 218: | ||

<td width='20%'></td> | <td width='20%'></td> | ||

</tr> | </tr> | ||

<tr style="border: solid;"> | <tr style="border: solid 1px !important;"> | ||

<th style="border: solid;">Type of test</th> | <th style="border: solid 1px !important;">Type of test</th> | ||

<th style="border: solid;">Detail</th> | <th style="border: solid 1px !important;">Detail</th> | ||

<th style="border: solid;">Description</th> | <th style="border: solid 1px !important;">Description</th> | ||

<th style="border: solid;">Status</th> | <th style="border: solid 1px !important;">Status</th> | ||

</tr> | </tr> | ||

<tr style="border: solid;"> | <tr style="border: solid 1px !important;"> | ||

<td style="border: solid !important;" rowspan="4">Initial preparation</td> | <td style="border: solid 1px !important;" rowspan="4">Initial preparation</td> | ||

<td style="border: solid !important;">Anchoring</td> | <td style="border: solid 1px !important;">Anchoring</td> | ||

<td style="border: solid;">Securely anchor the equipment with clamps</td> | <td style="border: solid 1px !important;">Securely anchor the equipment with clamps</td> | ||

<td style="border: solid;">-</td> | <td style="border: solid 1px !important;">-</td> | ||

</tr> | </tr> | ||

<tr style="border: solid;"> | <tr style="border: solid 1px !important;"> | ||

<td style="border: solid;">Grinder installation</td> | <td style="border: solid 1px !important;">Grinder installation</td> | ||

<td style="border: solid;">Install the equipment in the clamp</td> | <td style="border: solid 1px !important;">Install the equipment in the clamp</td> | ||

<td style="border: solid;">-</td> | <td style="border: solid 1px !important;">-</td> | ||

</tr> | </tr> | ||

<tr style="border: solid;"> | <tr style="border: solid 1px !important;"> | ||

<td style="border: solid;">Sample part</td> | <td style="border: solid 1px !important;">Sample part</td> | ||

<td style="border: solid;" rowspan="2">Cut an angle of 1 /4"*40 cm</td> | <td style="border: solid 1px !important;" rowspan="2">Cut an angle of 1 /4"*40 cm</td> | ||

<td style="border: solid;" rowspan="2">-</td> | <td style="border: solid 1px !important;" rowspan="2">-</td> | ||

</tr> | </tr> | ||

<tr style="border: solid;"> | <tr style="border: solid 1px !important;"> | ||

<td style="border: solid;">preparation</td> | <td style="border: solid 1px !important;">preparation</td> | ||

</tr> | </tr> | ||

<tr> | <tr> | ||

<td style="border: solid;" rowspan="4">Adjustments on assemblies (no load test)</td> | <td style="border: solid 1px !important;" rowspan="4">Adjustments on assemblies (no load test)</td> | ||

<td style="border: solid;" rowspan="2">Clamping of the angle grinder</td> | <td style="border: solid 1px !important;" rowspan="2">Clamping of the angle grinder</td> | ||

<td style="border: solid;">Keep the handle of the equipment immobilized.</td> | <td style="border: solid 1px !important;">Keep the handle of the equipment immobilized.</td> | ||

<td style="border: solid;" rowspan="2">Done</td> | <td style="border: solid 1px !important;" rowspan="2">Done</td> | ||

</tr> | </tr> | ||

<tr style="border: solid;"> | <tr style="border: solid 1px !important;"> | ||

<td style="border: solid;">Apply moderate force on the grinding wheel, from side to side and from top to bottom.</td> | <td style="border: solid 1px !important;">Apply moderate force on the grinding wheel, from side to side and from top to bottom.</td> | ||

</tr> | </tr> | ||

<tr style="border: solid;"> | <tr style="border: solid 1px !important;"> | ||

<td style="border: solid;" rowspan="2">Press grip</td> | <td style="border: solid 1px !important;" rowspan="2">Press grip</td> | ||

<td style="border: solid;">Mount and tighten the sample firmly in the press at 90°.</td> | <td style="border: solid 1px !important;">Mount and tighten the sample firmly in the press at 90°.</td> | ||

<td style="border: solid;" rowspan="2">Done</td> | <td style="border: solid 1px !important;" rowspan="2">Done</td> | ||

</tr> | </tr> | ||

<tr style="border: solid;"> | <tr style="border: solid 1px !important;"> | ||

<td style="border: solid;">Attempt to remove the sample by hand, applying moderate force.</td> | <td style="border: solid 1px !important;">Attempt to remove the sample by hand, applying moderate force.</td> | ||

</tr> | </tr> | ||

<tr style="border: solid;"> | <tr style="border: solid 1px !important;"> | ||

<td style="border: solid;" rowspan="3">Cut</td> | <td style="border: solid 1px !important;" rowspan="3">Cut</td> | ||

<td style="border: solid;" rowspan="3">Main test</td> | <td style="border: solid 1px !important;" rowspan="3">Main test</td> | ||

<td style="border: solid;">Cutting only the edge of the sample (reflowing)</td> | <td style="border: solid 1px !important;">Cutting only the edge of the sample (reflowing)</td> | ||

<td style="border: solid;" rowspan="3">- Done</td> | <td style="border: solid 1px !important;" rowspan="3">- Done</td> | ||

</tr> | </tr> | ||

<tr style="border: solid;"> | <tr style="border: solid 1px !important;"> | ||

<td style="border: solid;">Loosen the press and adjust to 45°(check that the work piece is aligned with the cutting area).</td> | <td style="border: solid 1px !important;">Loosen the press and adjust to 45°(check that the work piece is aligned with the cutting area).</td> | ||

</tr> | </tr> | ||

<tr style="border: solid;"> | <tr style="border: solid 1px !important;"> | ||

<td style="border: solid;">Make a 45° cut</td> | <td style="border: solid 1px !important;">Make a 45° cut</td> | ||

</tr> | </tr> | ||

<tr style="border: solid;"> | <tr style="border: solid 1px !important;"> | ||

<td style="border: solid;" rowspan="3">Accuracy of the result</td> | <td style="border: solid 1px !important;" rowspan="3">Accuracy of the result</td> | ||

<td style="border: solid;" rowspan="3">Measurement of cuts</td> | <td style="border: solid 1px !important;" rowspan="3">Measurement of cuts</td> | ||

<td style="border: solid;">Remove the sample, to detail:</td> | <td style="border: solid 1px !important;">Remove the sample, to detail:</td> | ||

<td style="border: solid;" rowspan="3">Done</td> | <td style="border: solid 1px !important;" rowspan="3">Done</td> | ||

</tr> | </tr> | ||

<tr style="border: solid;"> | <tr style="border: solid 1px !important;"> | ||

<td style="border: solid;">Appearance of the cut</td> | <td style="border: solid 1px !important;">Appearance of the cut</td> | ||

</tr> | </tr> | ||

<tr> | <tr> | ||

<td style="border: solid;">Accuracy of cutting angles</td> | <td style="border: solid 1px !important;">Accuracy of cutting angles</td> | ||

</tr> | </tr> | ||

</table> | </table> | ||

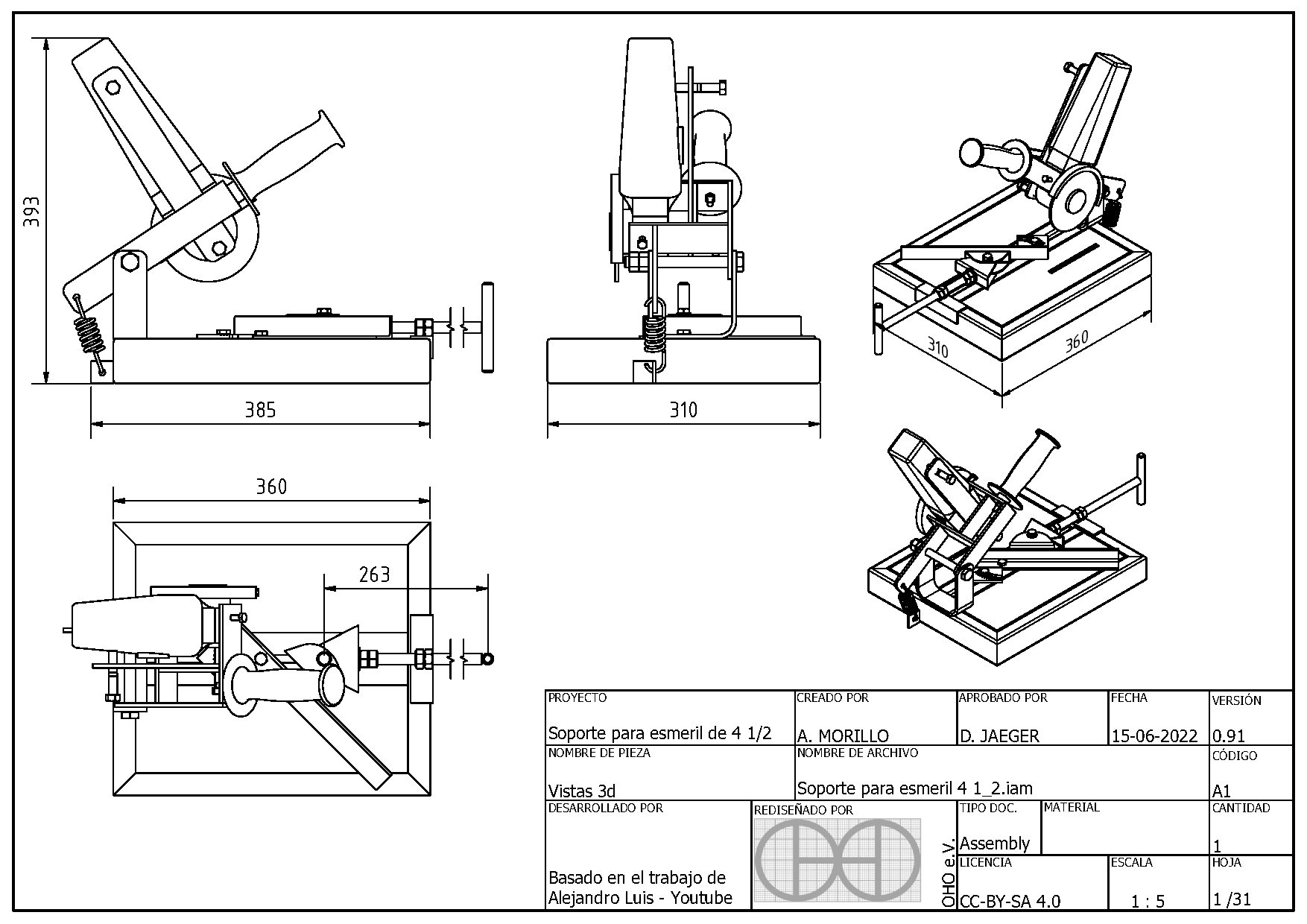

Revision as of 01:49, 12 April 2023

Project data

|

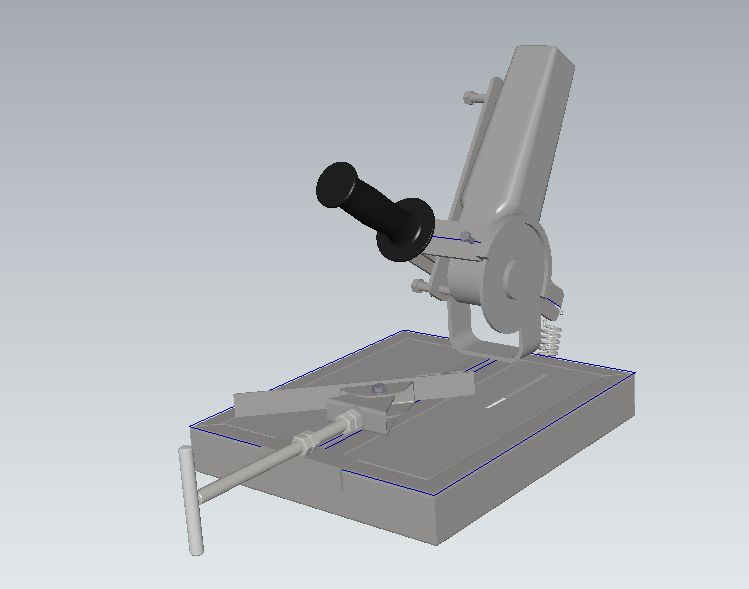

Category: Angle grinders URL (first publication): https://www.youtube.com/watch?v=l8SEEqtCDrc Keywords: grinder, angle, stand, diy, metal, machine, workshop, open source, cutting, disc License: CC BY-SA 4.0 Organization: OHO Project status: Active

Maturity of the project: prototype

Contains PDF-drawings: Yes CAD files are editable: Yes Assembly instructions are published: Yes Bill of materials is published: Yes

yes yes

|

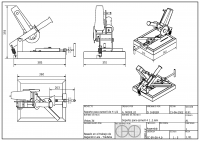

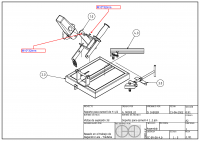

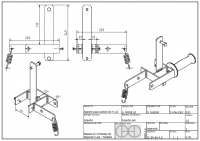

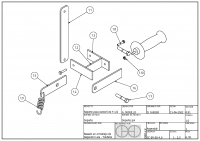

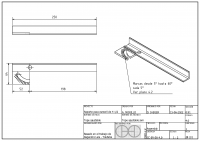

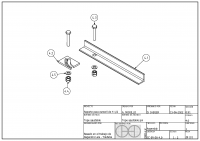

Technical documentation

PDF plans | |

|

|

Files: | |

CAD files | |

|

|

Files: | |

Tests, practical applications | |||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||

Files: | |||||||||||||||||||||||||||||||||||||||||

+ General Reviews

Reviews

| Pos. | Qty. | Part Name | Part code | Part Type | Specifications | Review Status | Show All Comments | |

|---|---|---|---|---|---|---|---|---|

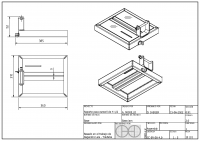

| A1 | 1 | 3D views | ||||||

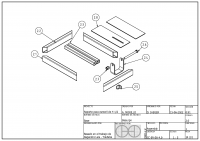

| A2 | 1 | Exploded 3D views | ||||||

| B | Parts list | |||||||

| 1.0 | 1 | Support | ||||||

| 1.1 | 1 | Seat | Production | Plate 1 1/2*3/16", A36 Steel | ||||

| 1.2 | 1 | Crossbar | Production | Plate 1 1/2*3/16", A36 Steel | ||||

| 1.3 | 1 | Side1 | Production | Plate 1 1/2*3/16", A36 Steel | ||||

| 1.4 | 1 | Side2 | Production | Plate 1 1/2*3/16", Stainless Steel A36 | ||||

| 1.5 | 1 | Extension1 | Production | Plate 1 1/2*3/16", Stainless Steel A36 | ||||

| 1.6 | 1 | Extension2 | Production | Plate 1 1/2*3/16", Steel A36 | ||||

| 1.7 | 2 | Rear stop | Standard | Hexagonal screw 3/8*2", Steel A36 | ||||

| 1.8 | 2 | Retaining screw | Standard | Hexagonal bolt 1/4*1". | ||||

| 1.9 | 1 | Retraction spring | Buy | Tension spring L: 90 mm, F 20 kg, D: 23mm | ||||

| 1.10 | 1 | Nut for handle | Standard | Hex nut 1/4", optional | ||||

| 2.0 | 1 | Base | ||||||

| 2.1 | 2 | Base frame1 | Production | 2*1" rectangular tube 14 gauge, A36 Steel | ||||

| 2.2 | 2 | Base frame2 | Production | Rectangular tube 2*1" 14 gauge, A36 Steel | ||||

| 2.3 | 2 | Guide base | Production | 1*1" 14-gauge rectangular tubing, A36 steel | ||||

| 2.4 | 1 | Fork1 | Production | Plate 1 1/2*3/16", A36 Steel | ||||

| 2.5 | 1 | Spring lug | Production | Angle 2*2*1/8", A36 Steel | ||||

| 2.6 | 1 | Articulation screw | Standard | Hex bolt 1/2*5", A36 Steel | ||||

| 2.7 | 2 | Articulation nut | Standard | Hex Nut 1/2 | ||||

| 2.8 | 2 | Base plate | Production | Sheet 3mm, Steel C45 | ||||

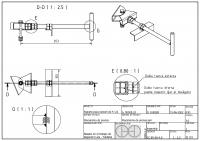

| 3.0 | 1 | Press mechanism | ||||||

| 3.1 | 1 | Power screw | Production | Threaded rod 1/2", A36 Steel | ||||

| 3.2 | 1 | Vice | Production | Rectangular pipe 2*1" 14 gauge, A36 Steel | ||||

| 3.3 | 1 | Vice holder | Production | 2*1" 14-gauge rectangular pipe, A36 Steel | ||||

| 3.4 | 1 | Press support | Production | Angle 1*1*1*-1/8", A36 Steel | ||||

| 3.5 | 1 | Handle | Production | 1/2" round bar, A36 Steel | ||||

| 3.6 | 4 | Stop nut | Standard | Hex Nut 5/16" Hex Nut | ||||

| 3.7 | 4 | Power nut | Standard | Hex Nut 1/2" Hex Nut | ||||

| 3.8 | 1 | Vise bolt | Standard | 5/16*3" Hex Bolt | ||||

| 3.9 | 2 | Jaw washer | Standard | Washer 3/8 | ||||

| 3.11 | 1 | Power Washer | Standard | Washer 1/2" Washer | ||||

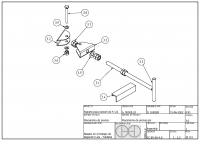

| 4.0 | 1 | Adjustable stop | ||||||

| 4.1 | 1 | Stop | Production | Angle 1*1*1/8", Steel A36 | ||||

| 4.2 | 1 | Stop pivot guide | Production | Plate 1 1/2*3/16, Steel A36 | ||||

| 4.3 | 2 | Press screw | Standard | Hexagonal Screw 5/16*2 | ||||

| 4.4 | 4 | Press nut | Standard | Hex Nut 5/16" Hex Nut | ||||

| 4.5 | 2 | Press washer | Standard | Washer 3/8" | ||||