Wind Mill Pump

From OHO - search engine for sustainable open hardware projects

|

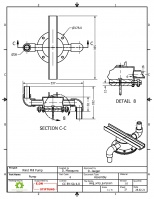

Wind Mill Pump Basic Data Category: Savonius wind turbines URL (first publication): https://www.youtube.com/watch?v=DfHtDeaLkGg Keywords: savonius, rotor, cheap, blueprints, construction, wind turbine, vawt, Brace Research Institute, oil drum, diaphragm pump, water License: CC BY-SA 4.0 Organization: Brace Research Institute Project status: Active Certification status: In process Technical documentation

Contains PDF-drawings: Yes CAD files are editable: Yes Assembly instructions are published: Yes Bill of materials is published: Yes

yes yes

|

Description

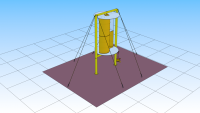

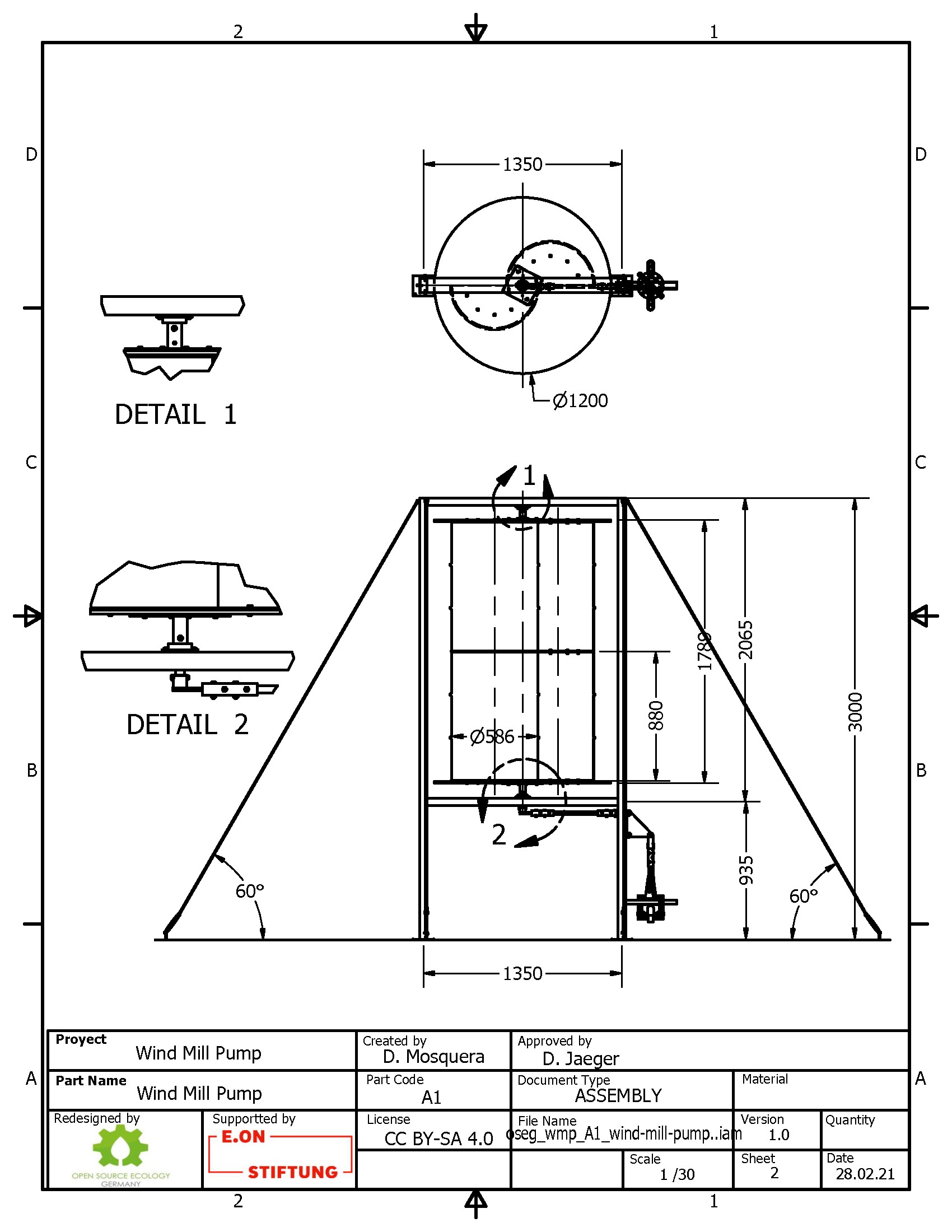

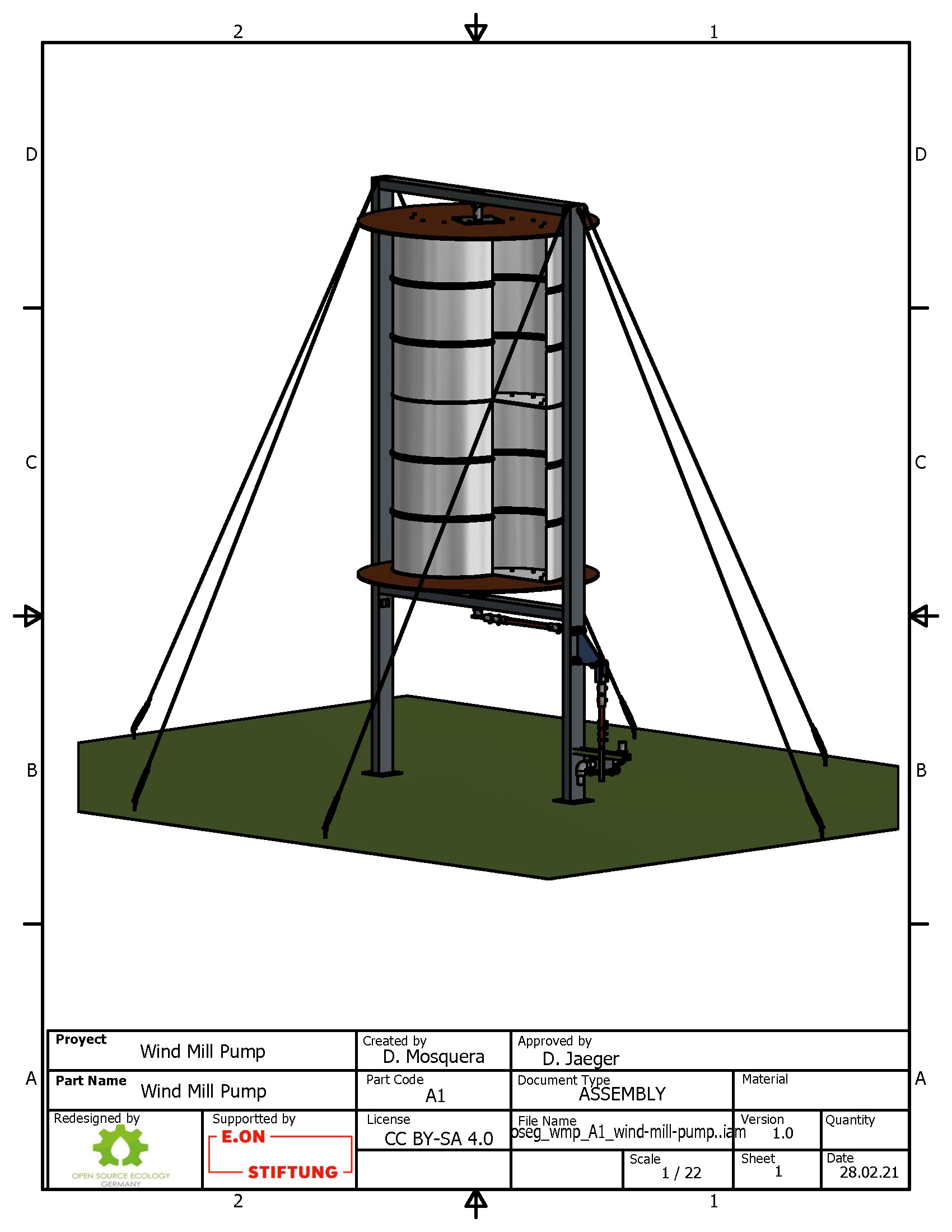

Plans and 3d models to build a DIY equipment to pump water using a Savonius turbine and a diaphragm pump.

Original design by Brace Research Institute, published under a CC-BY-SA 4.0 license.

This project was supported by the german Foundation E.ON Stiftung.

Technical documentation

PDF Plans | |

|

|

Files: | |

CAD Files | |

|

|

Files: | |

+ General Reviews

Parts list

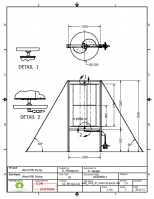

| Pos. | Qty. | Part Name | Part code | Part Type | Specifications | Review Status | Show All Comments | |

|---|---|---|---|---|---|---|---|---|

| A1 | wind mill pump | A1 | ||||||

| A2 | wind mill pump | A2 | ||||||

| B | Part list | B | ||||||

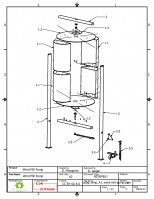

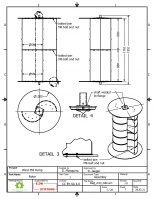

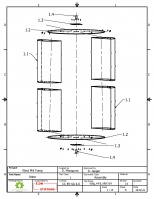

| 1 | The Rotor | 1 | ||||||

| 1.1 | 4 | 1/2 oil drum | 1.1 | Production | 200-litre drum 867 height x 584 diam | |||

| 1.2 | 2 | plates plywood | 1.2 | Production | plywood | |||

| 1.3 | 2 | flange support | 1.3 | Production | structural steel A36 | |||

| 1.4 | 2 | rotor shaft | 1.4 | Production | steel C45 | |||

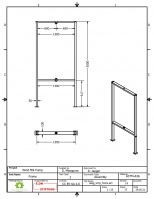

| 2 | Frame | 2 | ||||||

| 2.1 | 2 | supporting laths 50x25x3000 | 2.1 | structural steel A36 | ||||

| 2.2 | 2 | supporting laths 50x25x1300 | 2.2 | structural steel A36 | ||||

| 2.3 | 1 | top adaptor | 2.3 | Production | steel C45 | |||

| 2.4 | 1 | bottom adaptor | 2.4 | Production | steel C45 | |||

| 2.5 | 2 | self alighing bearing | 2.5 | Standard | bearing 6205 - 25x56x15 | |||

| 2.6 | 2 | bearing support | 2.6 | Production | steel C45 | |||

| 2.7 | 2 | rectangular flancher | 2.7 | Production | steel C45 | |||

| 2.8 | 3 | securing bolt | 2.8 | Standard | round head screw, galvanized steel | |||

| 2.9 | 3 | securing nut | 2.9 | Standard | galvanized steel | |||

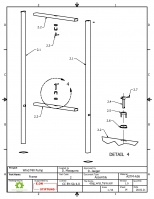

| 3 | drive | 3 | Production | |||||

| 3.1 | 1 | Excentric | 3.1 | Production | steel C45 | |||

| 3.2 | horizontal connecting rod | 3.2 | ||||||

| 3.2.1 | connecting rod | 3.2.1 | Standard | connecting rod of a motorcycle or small car engine | ||||

| 3.2.2 | 2 | water pipe 1"x150 | 3.2.2 | Standard | galvanized pipe 1" | |||

| 3.2.3 | rod horizont 1x1x 600 | 3.2.3 | Production | wood strip | ||||

| 3.2.4 | 1 | nipple 1" | 3.2.4 | Standard | galvanized pipe 1" fitting | |||

| 3.2.5 | 2 | Sheet metal bracket | 3.2.5 | Production | steel C45 | |||

| 3.3 | bell crank | 3.3 | Production | steel C45 | ||||

| 3.4 | pivot plate | 3.4 | Production | sheet steel C45 | ||||

| 3.5 | adjustable pumprod forkend | 3.5 | ||||||

| 3.5.1 | 2 | Sheet metal bracket | 3.5.1 | Production | sheet steel C45 | |||

| 3.5.2 | 1 | nipple 1" | 3.5.2 | Standard | galvanized pipe 1" fitting | |||

| 3.5.3 | 1 | water pipe 1"x150 | 3.5.3 | Standard | galvanized pipe 1" | |||

| 3.5.4 | 1 | rod vert 1x1x 600 | 3.5.4 | Production | wood strip | |||

| 3.5.5 | 1 | stirrup | 3.5.5 | Production | structural steel A36 | |||

| 3.5.6 | 2 | sheet metal bracket | 3.5.6 | Production | ||||

| 3.6 | 16 | bolts M6x30 | 3.6 | Standard | round head screw, galvanized steel | |||

| 3.7 | 16 | nut M6 | 3.7 | Standard | galvanized steel | |||

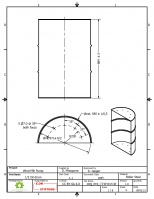

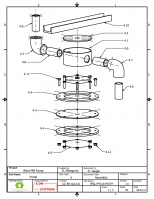

| 4 | 1 | pump | 4 | |||||

| 4.1 | 1 | pumpbody oring | 4.1 | Production | steel C45 | |||

| 4.2 | 1 | pumpbody disk | 4.2 | Production | steel C45 | |||

| 4.3 | 1 | rubber diafphragm | 4.3 | Production | rubber | |||

| 4.4 | 2 | flange ring | 4.4 | Production | steel C45 | |||

| 4.5 | 2 | spacer | 4.5 | Production | wood | |||

| 4.6 | 4 | galvanised pipe 1" x 50 | 4.6 | Standard | galvanized pipe 1" | |||

| 4.7 | 2 | galvanised elbow 1"-90º | 4.7 | Standard | galvanized pipe 1" fitting | |||

| 4.8 | 1 | inlet valve | 4.8 | Standard | galvanized check valve 1" fitting | |||

| 4.9 | 1 | outlet valve | 4.9 | Standard | galvanized check valve 1" fitting | |||

| 4.10 | 1 | Mounting bar - U1"x2"x6x 350 | 4.10 | Standard | structural steel profile | |||

| 4.11 | 8 | bolts M6x30 | 4.11 | Standard | hexagonal head screw, galvanized steel | |||

| 4.12 | 8 | nut M6 | 4.12 | Standard | galvanized steel | |||