Difference between revisions of "Parts list"

Inddigital (talk | contribs) (Created page with " == Definición == Como primer paso para desarrollar el Proyecto, se debe elaborar la Lista de piezas con la información disponible de las partes y ensamblajes, dicha lista d...") |

Inddigital (talk | contribs) |

||

| (28 intermediate revisions by 4 users not shown) | |||

| Line 1: | Line 1: | ||

[[de:Stuecklisten]] | |||

[[es:Lista_de_piezas]] | |||

== Definition == | |||

As a first step in developing the Project, the Parts List should be developed with the available parts and assemblies information, containing all the tangible and functional components that can contribute to the cost of the Project. The components may be numbered in the form of a ''Simple Parts List'' or contain layers of hierarchy, in which case, it is a ''Structured Parts List''. | |||

== | == Guidelines == | ||

< | The following are some guidelines to keep in mind, when developing the Parts list:<br/><br/>. | ||

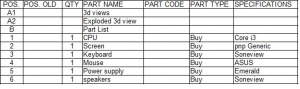

[[File:Partlist-simple.jpg|thumb|<small>'''[[Media:Oseg_simple_part-list.csv|Simple Parts List]]'''</small>]] | |||

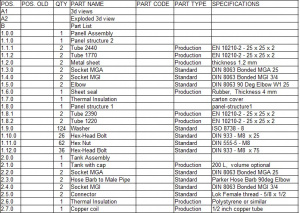

[[File:Partlist-structured.jpg|thumb|<thumb|<small>'''[[Media:Oseg_swh_part-list.csv|Structured Parts list]]'''</small>]] | |||

A | A Simple Parts List is used, when in the assembly or equipment, none of its components are disassembled or broken down into more basic parts by basic shop processes. | ||

A structured Parts List is used when, in the assembly or equipment, any of its components can be disassembled or broken down into more basic parts that can be manufactured or procured. | |||

*The Parts List must contain the following columns (column names must be exactly as indicated): | |||

* | *POS -> Is the number assigned to the part or assembly. | ||

* | **For each level of hierarchy, use Arabic numerals, cardinal and in ascending order 1, 2, 3.... | ||

* | **It is preferred to list the most important parts or assemblies first, according to criteria such as function, cost, size, among others. | ||

* | **For Structured Parts List, the assemblies and parts are numbered, separating the levels with dots, the higher level items are filled with as many zeros to the right as there are levels in the list (see examples). | ||

*POS. OLD -> If you have previous drawings of the assembly or equipment, it corresponds to the number assigned in these. | |||

*QTY -> It is the total quantity required for the part or assembly within the assembly to which it belongs. | |||

**Whole quantities are preferred, e.g. for two lengths of cable 1.5 meters each, the name would be '1.5 m cable', and the quantity 2. | |||

** | **There may be cases of approximate or non-integer quantities, in which case estimates are used, in these cases, specifications and Technical Notes may be included to indicate estimation methods and units used. | ||

** PART NAME -> | *PART NAME -> It is the unique name assigned to the part or assembly. | ||

*** | **It must be free of redundancies. | ||

*** | **Must be related to functionality. | ||

** | **It should not include detailed technical specifications. | ||

** | **It must be written only with the first letter capitalized, except when it includes proper names, international acronyms or relevant terms at Open Hardware level. | ||

**Do not include numbers or hyphens as spaces. | |||

**If necessary, you may include a suffix number for duplicate names. | |||

*PART CODE-> This field will be used later, leave it blank for now. | |||

*PART TYPE -> This is a classifier that applies to parts, not assemblies, it can have the following values: | |||

**Production -> for manufactured parts or parts undergoing some modification or forming process. | |||

**Standard -> for standardized or catalog parts, such as screws, connectors, standardized electrical components, among others. | |||

** | **Buy -> for purchased and non-standard parts, which must be purchased for the project. | ||

** | *SPECIFICATIONS -> Must be indicated, mainly on the parts, the information necessary for their manufacture or purchase: | ||

** | **For manufactured parts, indicate the [[#materials|material]], surface treatment, special manufacturing processes (if applicable); as well as, dimensions specific to the material, such as sheet thickness, profile section, bolt sizes, among others; exclude other measurable information in the drawings, such as profile length, pipe length, among others. | ||

**For standard parts, indicate DIN designation or similar information. | |||

**For purchased parts, indicate information such as technical data, supplier, order number, website, among others. | |||

* | Names of parts, assemblies, specifications and other technical information should be written in English, it is recommended to use [http://www.deepl.com deepl.com]. | ||

** | At the beginning of the Parts List, the following lines should be included: | ||

** | * One or more lines for the project overview pages, which includes all subassemblies or assemblies. | ||

** | **The initial pages showing the total assembled (non-explosion) assembly are all called A1. | ||

**All A1 pages can be grouped on a single line, indicating the page range in the SHEET column. | |||

* | **After the assembled set pages, a [https://en.wikipedia.org/wiki/Exploded-view_drawing explosion] view of the Project named A2 should be included. | ||

** | *One or more lines for the pages corresponding to the Parts List. | ||

** | **It is identified in the POS field with the letter B. | ||

** | **In case more than one page is required to display the entire Part list, these are identified with a sequential number: B1, B2.... | ||

**In case of several lines, they can be summarized in a single row identified as B. | |||

* | For validation in OHO, the developer must deliver The Parts List preferably in CSV format, with UTF8 encoding, however, it can be an excel spreadsheet with the required information, this allows highlighting the data with comments, cell colors, among others. | ||

** | *The name of the Parts List file is unique, must be in lower case and must be composed of: | ||

** | **Organization abbreviation, example: ''oseg'' for [https://opensourceecology.de/ Open Source Ecology]. | ||

** | **Underscore separator '_' | ||

*** | **Project abbreviation, e.g. ''sp'' for [https://en.oho.wiki/wiki/Screw_Press Screw Press] | ||

** | **Underscore separator | ||

** | **Underscore separator '_' | ||

**Project name without spaces, example screw-press | |||

*Complete example for the name: ''oseg_sp_screw-press'' | |||

*The file name for the first file of the project, e.g. ''oseg_sp_screw-press''. | |||

*The file name for the first version submitted must end in _0.1, for the second version it will be _0.2 and so on. | |||

*When a file is approved, OHO will name it as _1.0 as the first approved version, _2.0 as the second approved version and so on. | |||

== Additional notes == | |||

* In terms of hierarchy, fully assembled equipment is considered level 0. | |||

* In a first exploded view, the resulting components are level 1. | |||

* If the level 1 components are not disassemblable, it is a simple list (1 level). | |||

* If the level 1 components are disassemblable, a second exploded view will generate level 2 components (structured list). | |||

* If level 2 components are disassemblable, a third exploded view will generate level 3 components (3-level structured list). | |||

* A maximum of 3 levels of hierarchy is established<!-- , for very complex assemblies, requiring 4 levels, OHO must review and approve these cases -->. | |||

* Any assembly of a given level may contain a maximum of 15 components, otherwise, these components must be grouped together to form sub-assemblies of the next level. | |||

* In case of a simple parts list, the developer can start the CAD modeling even before the approval of the csv document or its similar in excel. | |||

* For projects with a structured parts list, it is preferred that the developer starts the CAD modeling after the csv document has been approved by OHO, in such cases, the deliverable may include a freehand image or sketch, indicating the part numbers and/or components. | |||

* If there are identical components in the same assembly, they must be grouped in a single item, with a name that helps to identify them, for example, length of a profile, and the total quantity must be indicated for this item. | |||

* In Structured List, certain elements common to several sub-assemblies such as bolts, pipe fittings, among others, should not have the highest level of hierarchy, but should belong to the most important assembly to which they are related. | |||

<div id="materials"></div> | |||

According to the application, the following materials are preferred: | |||

{| class = "wikitable" | |||

|- | |||

!| Material | |||

!| Class | |||

!| Preferred use | |||

|- | |||

| rowspan="4" | Steel | |||

| Steel A36 | |||

| Structural and general purpose profiles | |||

|- | |||

| Steel C45 | |||

| Machined parts, sheet metal | |||

|- | |||

| Steel 9260<br> quenched and tempered | |||

| | Cutting blades (spring steel)<br> also DIN 60SiCr7 | |||

|- | |||

| Steel A53<br> Black iron | |||

| Black iron pipes | |||

|- | |||

| rowspan="3" | Timber and wood by-products | |||

| Kiln-dried wood | |||

| General use | |||

|- | |||

| Hardwood | |||

| | High dimensional stability | |||

|- | |||

| MDF / plywood | |||

| | General purpose, low humidity | |||

|} | |||

=== Commercial and standard components === | |||

For standard components such as fasteners, pipe fittings, among others, search in the following order: | |||

* DIN libraries of the CAD systems used | |||

* Other libraries of the CAD systems used | |||

* Links provided by OHO | |||

* Internet libraries, mainly in metric system | |||

* Wikipedia | |||

* Other | |||

Here are some useful links for commercial and standard components: | |||

* Woods and derivatives: | |||

**https://www.dlubal.com/en/cross-section-properties/timber-rectangles | |||

**https://harpertimber.com.au/industry-standard-timber-sizes/ | |||

**https://theplywoodspecifiersguide.co.uk/wp-content/uploads/2018/11/Hanson-Plywood_Product-Guide-2019_Digital.pdf | |||

**https://translate.google.com/translate?sl=auto&tl=en&u=https://www.holz-faulhaber.de/holzhandel/schnittholz/ | |||

*Screws: | |||

**https://boltport.com/weights/din-933/ | |||

**https://www.lederer-online.com/en/products/overview-normedstandardized-parts/screws-bolts-thread-rods/ | |||

**https://www.engineeringtoolbox.com/wood-screw-shank-diameter-pilot-hole-d_1460.html | |||

**https://www.fasteners.eu/standards/DIN/97/ | |||

**https://www.reddit.com/r/woodworking/comments/2takxv/wood_magazines_screw_chart_traditional_wood/ | |||

*Metal profiles: | |||

**https://www.dlubal.com/en/cross-section-properties/ | |||

**https://estructurando.net/2015/05/05/tablas-de-perfiles-metalicos-de-varios-paises/ | |||

*Metal or plastic drums: | |||

**http://generalsteeldrum.com/wp-content/uploads/2017/04/iso_th_steel_drums.pdf | |||

**https://www.schuetz-packaging.net/downloads/broschueren/broschuere-schuetz-kunststofffaesser-stahlfaesser/brochure-schuetz-pe-drums-steel-drums-en.pdf?cid=a0y | |||

*Nails | |||

**https://en.wikipedia.org/wiki/Nail_(fastener) | |||

*Hinges | |||

**https://www.schraubenbude.de/beschlaege-und-verbinder/scharniere/breite-scharniere-din-7954-d-verzinkt/ | |||

**https://www.impaconsumables.com/product/492525-hinge-stainless-steel-72x100mm-schwepper-8001/?v=a99877f71bd9 | |||

*Sheet metal gauge | |||

**https://en.wikipedia.org/wiki/Sheet_metal#Gauge | |||

*Corrugated sheet metal | |||

**https://www.cladco.co.uk/13-3-0-7-thick-galvanised-corrugated-roofing-sheets | |||

*Ropes | |||

**https://www.aliexpress.com/i/32961955694.html | |||

*Wire gauges | |||

**https://en.wikipedia.org/wiki/Standard_wire_gauge | |||

*Ceramic tiles | |||

**https://theconstructor.org/question/what-are-the-standard-sizes-of-tiles-available-in-the-market/ | |||

Latest revision as of 18:53, 19 April 2022

Definition

As a first step in developing the Project, the Parts List should be developed with the available parts and assemblies information, containing all the tangible and functional components that can contribute to the cost of the Project. The components may be numbered in the form of a Simple Parts List or contain layers of hierarchy, in which case, it is a Structured Parts List.

Guidelines

The following are some guidelines to keep in mind, when developing the Parts list:

.

A Simple Parts List is used, when in the assembly or equipment, none of its components are disassembled or broken down into more basic parts by basic shop processes. A structured Parts List is used when, in the assembly or equipment, any of its components can be disassembled or broken down into more basic parts that can be manufactured or procured.

- The Parts List must contain the following columns (column names must be exactly as indicated):

- POS -> Is the number assigned to the part or assembly.

- For each level of hierarchy, use Arabic numerals, cardinal and in ascending order 1, 2, 3....

- It is preferred to list the most important parts or assemblies first, according to criteria such as function, cost, size, among others.

- For Structured Parts List, the assemblies and parts are numbered, separating the levels with dots, the higher level items are filled with as many zeros to the right as there are levels in the list (see examples).

- POS. OLD -> If you have previous drawings of the assembly or equipment, it corresponds to the number assigned in these.

- QTY -> It is the total quantity required for the part or assembly within the assembly to which it belongs.

- Whole quantities are preferred, e.g. for two lengths of cable 1.5 meters each, the name would be '1.5 m cable', and the quantity 2.

- There may be cases of approximate or non-integer quantities, in which case estimates are used, in these cases, specifications and Technical Notes may be included to indicate estimation methods and units used.

- PART NAME -> It is the unique name assigned to the part or assembly.

- It must be free of redundancies.

- Must be related to functionality.

- It should not include detailed technical specifications.

- It must be written only with the first letter capitalized, except when it includes proper names, international acronyms or relevant terms at Open Hardware level.

- Do not include numbers or hyphens as spaces.

- If necessary, you may include a suffix number for duplicate names.

- PART CODE-> This field will be used later, leave it blank for now.

- PART TYPE -> This is a classifier that applies to parts, not assemblies, it can have the following values:

- Production -> for manufactured parts or parts undergoing some modification or forming process.

- Standard -> for standardized or catalog parts, such as screws, connectors, standardized electrical components, among others.

- Buy -> for purchased and non-standard parts, which must be purchased for the project.

- SPECIFICATIONS -> Must be indicated, mainly on the parts, the information necessary for their manufacture or purchase:

- For manufactured parts, indicate the material, surface treatment, special manufacturing processes (if applicable); as well as, dimensions specific to the material, such as sheet thickness, profile section, bolt sizes, among others; exclude other measurable information in the drawings, such as profile length, pipe length, among others.

- For standard parts, indicate DIN designation or similar information.

- For purchased parts, indicate information such as technical data, supplier, order number, website, among others.

Names of parts, assemblies, specifications and other technical information should be written in English, it is recommended to use deepl.com. At the beginning of the Parts List, the following lines should be included:

- One or more lines for the project overview pages, which includes all subassemblies or assemblies.

- The initial pages showing the total assembled (non-explosion) assembly are all called A1.

- All A1 pages can be grouped on a single line, indicating the page range in the SHEET column.

- After the assembled set pages, a explosion view of the Project named A2 should be included.

- One or more lines for the pages corresponding to the Parts List.

- It is identified in the POS field with the letter B.

- In case more than one page is required to display the entire Part list, these are identified with a sequential number: B1, B2....

- In case of several lines, they can be summarized in a single row identified as B.

For validation in OHO, the developer must deliver The Parts List preferably in CSV format, with UTF8 encoding, however, it can be an excel spreadsheet with the required information, this allows highlighting the data with comments, cell colors, among others.

- The name of the Parts List file is unique, must be in lower case and must be composed of:

- Organization abbreviation, example: oseg for Open Source Ecology.

- Underscore separator '_'

- Project abbreviation, e.g. sp for Screw Press

- Underscore separator

- Underscore separator '_'

- Project name without spaces, example screw-press

- Complete example for the name: oseg_sp_screw-press

- The file name for the first file of the project, e.g. oseg_sp_screw-press.

- The file name for the first version submitted must end in _0.1, for the second version it will be _0.2 and so on.

- When a file is approved, OHO will name it as _1.0 as the first approved version, _2.0 as the second approved version and so on.

Additional notes

- In terms of hierarchy, fully assembled equipment is considered level 0.

- In a first exploded view, the resulting components are level 1.

- If the level 1 components are not disassemblable, it is a simple list (1 level).

- If the level 1 components are disassemblable, a second exploded view will generate level 2 components (structured list).

- If level 2 components are disassemblable, a third exploded view will generate level 3 components (3-level structured list).

- A maximum of 3 levels of hierarchy is established.

- Any assembly of a given level may contain a maximum of 15 components, otherwise, these components must be grouped together to form sub-assemblies of the next level.

- In case of a simple parts list, the developer can start the CAD modeling even before the approval of the csv document or its similar in excel.

- For projects with a structured parts list, it is preferred that the developer starts the CAD modeling after the csv document has been approved by OHO, in such cases, the deliverable may include a freehand image or sketch, indicating the part numbers and/or components.

- If there are identical components in the same assembly, they must be grouped in a single item, with a name that helps to identify them, for example, length of a profile, and the total quantity must be indicated for this item.

- In Structured List, certain elements common to several sub-assemblies such as bolts, pipe fittings, among others, should not have the highest level of hierarchy, but should belong to the most important assembly to which they are related.

According to the application, the following materials are preferred:

| Material | Class | Preferred use |

|---|---|---|

| Steel | Steel A36 | Structural and general purpose profiles |

| Steel C45 | Machined parts, sheet metal | |

| Steel 9260 quenched and tempered |

Cutting blades (spring steel) also DIN 60SiCr7 | |

| Steel A53 Black iron |

Black iron pipes | |

| Timber and wood by-products | Kiln-dried wood | General use |

| Hardwood | High dimensional stability | |

| MDF / plywood | General purpose, low humidity |

Commercial and standard components

For standard components such as fasteners, pipe fittings, among others, search in the following order:

- DIN libraries of the CAD systems used

- Other libraries of the CAD systems used

- Links provided by OHO

- Internet libraries, mainly in metric system

- Wikipedia

- Other

Here are some useful links for commercial and standard components:

- Woods and derivatives:

- https://www.dlubal.com/en/cross-section-properties/timber-rectangles

- https://harpertimber.com.au/industry-standard-timber-sizes/

- https://theplywoodspecifiersguide.co.uk/wp-content/uploads/2018/11/Hanson-Plywood_Product-Guide-2019_Digital.pdf

- https://translate.google.com/translate?sl=auto&tl=en&u=https://www.holz-faulhaber.de/holzhandel/schnittholz/

- Screws:

- https://boltport.com/weights/din-933/

- https://www.lederer-online.com/en/products/overview-normedstandardized-parts/screws-bolts-thread-rods/

- https://www.engineeringtoolbox.com/wood-screw-shank-diameter-pilot-hole-d_1460.html

- https://www.fasteners.eu/standards/DIN/97/

- https://www.reddit.com/r/woodworking/comments/2takxv/wood_magazines_screw_chart_traditional_wood/

- Metal profiles:

- Metal or plastic drums:

- Hinges

- Sheet metal gauge

- Corrugated sheet metal