Difference between revisions of "Certification instructions"

| Line 162: | Line 162: | ||

* Approval and signature of Authorities by the external certification body for validation according to [[DIN Spec 3105]]. | * Approval and signature of Authorities by the external certification body for validation according to [[DIN Spec 3105]]. | ||

== | == Reviewers == | ||

The [[Certifcation platform#reviewers|Reviewers]] have the task to technically analyse all the Project documentation, for which, they must have gone through the [[#sing-up|registration process]] in the same way as for the [[Certifcation platform#applicant|Applicant]]. It must also have the role of ''certificarion_reviewer'', as indicated in [[#reviewers-designation|Reviewer designation]]. | |||

Each [[Certifcation platform#reviewers|Reviewer]] must comply with the aspects mentioned below: | |||

=== | === Analysis of Technical Documentation === | ||

* | * Enter the [[#project_page|project page]]. | ||

* | * Analyse all available information, especially the assembly instructions, which includes: | ||

** | ** Correct references between parts in the [[Technical drawings]] and the [[Parts list]] . | ||

** | ** Well explained manufacturing processes for special parts or joining means. | ||

** | ** Consistency in the information shown, it must make sense in technical and [[https://es.wikipedia.org/wiki/Hardware_libre Open Hardware]] terms. | ||

=== | === Release of non-conformities === | ||

[[File:Project comments.JPG|thumb|<small>''' | [[File:Project comments.JPG|thumb|<small>'''Comments in a project'''</small>]] | ||

[[File:Project action required.JPG|thumb|<small>'''Item | [[File:Project action required.JPG|thumb|<small>'''Item marked as ''Action required'''''</small>]] | ||

On the [[#project_page|project page]], comments on technical aspects can be made, these comments are the channel in which non-conformities are issued. | |||

A comment or non-conformity must be issued in the following cases: | |||

* Information is missing in order to be able to classify or recognise a part or assembly. | |||

* Information about a supplier is missing (links to websites tend to be modified). | |||

* Missing information on a purchased part, in order to be able to locate it in current markets. | |||

* Missing measurements or other specifications in the [[Technical drawings]]. | |||

* Lack of coherence in the specifications, with respect to the assembly of the parts. | |||

* Missing fields in the [[#part_list|Parts list]]. | |||

* Depending on the type of assembly: | |||

** There must exist for each part, a [[Technical drawings|plan in PDF]] and its respective [[CAD files|CAD file]] (the latter, with the purpose of being able to review the 3D information in other CAD systems different from the one that has generated the parts). | |||

** The 3D printing parts must be accompanied by their STL file, in addition to their [[Technical drawings|PDF drawing]] and their [[CAD files|CAD file]]. | |||

** For printed circuit boards (PCB), the addresses of their components must be included. | |||

* In case of confusing information or obvious mistakes, a friendly comment should be left, pointing out the mistake in the corresponding item. | |||

* In case of problems regarding the Project in general, there is an extra field in the [[#part_list|Parts list]], where comments can be added | |||

* Those items that require some correction by the [[Certifcation platform#applicant|Applicant]], must be marked as ''Action required'', in the [[#project_page|Project page]], action ''Edit'', tab ''Part list''. | |||

* This process can be repeated as long as there are comments or non-conformities with corrections to be made and not all the items of the [[#part_list|Part list]] are approved, through which, communication with the [[Certifcation platform#applicant|Applicant]] must always be maintained. | |||

=== Project Approval === | |||

[[File:Project aproved.JPG|thumb|<small>'''Item marked as ''Approved'''''</small>]] | |||

After all non-conformities have been resolved, you should: | |||

* Mark each item in the [[#part_list|Part list]] as ''Approved'', on the [[#project_page|Project page]], action ''Edit'', tab ''Part list''. | |||

* Add a final comment including ''OK, FINISHED''. | |||

* Notify the [[Certifcation platform#coordinator|Coordinator|Coordinator]], about the Project Approval. | |||

== Equipo de evaluación de conformidad (CAB) == | == Equipo de evaluación de conformidad (CAB) == | ||

El [[Certifcation platform#cab-team|Equipo CAB]] tiene acceso los datos de contacto de los [[Certifcation platform#reviewers|Revisores]] y del [[Certifcation platform#applicant|Aplicante]], pudiendo siempre intervenir en la resolución de no coformidades y obteniendo información directa para la emisión del [[Certification processes#obs|Documento de Certificación]]. | El [[Certifcation platform#cab-team|Equipo CAB]] tiene acceso los datos de contacto de los [[Certifcation platform#reviewers|Revisores]] y del [[Certifcation platform#applicant|Aplicante]], pudiendo siempre intervenir en la resolución de no coformidades y obteniendo información directa para la emisión del [[Certification processes#obs|Documento de Certificación]]. | ||

Revision as of 16:48, 23 February 2021

Overview of instructions according to the role in the OHO

The instructions to follow for the Certification processes, will depend on the participant and his role in the process.

Here are the specific procedures for each role in the certification of a project:

Applicant

The Applicant initiates and terminates the Certification processes, for which it must comply with the following procedures:

Registration on the Certification Platform

The applicant|Applicant must be registered with OHO, via:

https://en.oho.wiki/wiki/Special:CreateAccount

Project data upload

For the project to exist in the platform, you must start by uploading its basic information and then the rest of the documentation. This is done by logging in at: https://en.oho.wiki/wiki/Special:FormEdit/Project

.

Here the user must upload the following information:

- Basic data - The following information must be entered:

- Project name in three languages.

- Project Category - select from the levels offered by the system.

- One or more images of the project:

- They must be clear images, which can be understood.

- Without distortions.

- With a suitable resolution, preferably around 600 to 800 pixels wide.

- Keywords:

- Must not contain redundancies.

- They must be related to technical aspects of the project.

- At least five keywords.

- URL (first publication): Web address from which the information on the project was obtained, if available.

- Status of the translation - Select from the options:

- No translation.

- Automatic translation.

- In process.

- Manual.

- Description of the project:

- Briefly explain what it consists of.

- Technologies used.

- Some important materials

- Highlight advantages such as cost, innovation, efficiency, etc.

- Additional fields - These are initially optional fields, consisting mainly of the following aspects.

- Licence.

- Source.

- Organisation.

- Project Status.

- Project Maturity.

- Contains Mechanical Hardware.

- Licence for mechanical hardware.

- Contains electronic hardware.

- Contains original software.

- Published assembly instructions.

- BOM published.

- Conflict management system in place.

- Versioning system in place.

- Contains PDF drawings.

- Technology Readiness Level (TRL).

- When this information is saved, a page is created in OHO with the name of the Project that has been entered.

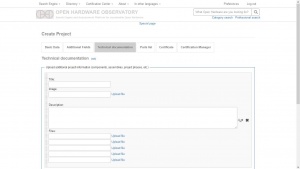

Uploading technical documentation

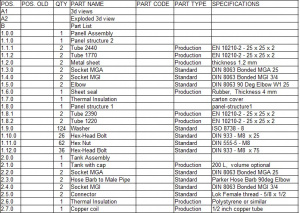

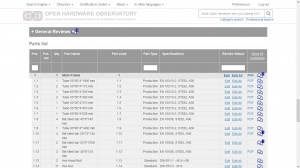

- Parts list: It is important to enter each part and assembly correctly, with the right information and in the right order. The Parts list is loaded in the Part List tab.

- It can be entered manually by filling in each information field for each item in the list.

- It can be entered manually by filling in each information field for each item in the list.

- The Part list can also be uploaded by accessing the Import from CSV option, through which the already defined CSV file can be uploaded.

- The Part list can also be uploaded by accessing the Import from CSV option, through which the already defined CSV file can be uploaded.

- CAD files, Technical drawings and Other documents:

- Upload a PDF file containing the Project drawings, already defined in Technical drawings.

- Upload the compressed folder with the files, already defined in CAD files.

- Similarly, upload the compressed folder with the exchange files, also defined in CAD files.

- Upload also each technical document of importance for the development of the Project.

- When uploading this information, an image or view representing the set of plans or documents being uploaded must be included in the same form, this can be one of the images previously uploaded as indicated in Basic data.

Request certification for the Project

After uploading the Technical documentation of the Project, the Applicant must make the Request certification for your project of the Project, which will then be contacted by OHO to formalise the process, the following is highlighted:

- The user assigned to the Applicant must have all the required information in order to be contacted and verified.

- The Project must have all the fields corresponding to Basic data entered.

- The Parts list must have been entered correctly.

Project Corrections

If during the review of the Project documentation, the Reviewers team issues any non-conformities (Reviews), the applicant|Applicant must proceed to make the necessary corrections and edit the project information in the same way the information was entered.

- The communication channel to receive the non-conformities is the same Project page, in which the Applicant must log in regularly, these are displayed as comments superimposed on the Parts list.

- Non-conformities on those items marked as Action Required must be addressed by the Reviewers.

- Corrections must be made in a timely manner, in order to expedite the certification process.

- The Applicant, may comment on the Reviews or add further comments in order to communicate any issue resolution issues.

Receipt of the Certification Document

The final step of the Certification processes, is the reception by the Applicant, of the Certification Document, for which it is contacted by the established channels.

- The applicant must read in detail the document to be received.

- The applicant must accept the terms of the document.

- Finally, the applicant, is directed to a page where he/she can download the document and fill in some fields about his/her experience during the Certification processes.

Coordinador

El Coordinador, como ente rector por parte de OHO, es responsable del Certification processes ya que monitorea, habilita e impulsa todas las etpas. Sus principales actividades son:

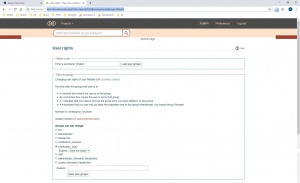

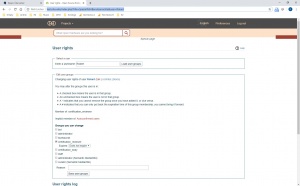

Designation of the Conformity Assessment Body (CAB)

]]

The CAB-team must be designated and activated, once the Applicant performs the Request certification for your project of the Project, as this team must participate, among others, in the designation of the Reviewers.

For each member of the CAB-team, the following must be fulfilled:

- If the Evaluator user does not have the required role:

- Login to the special page User Rights.

- Enter the user's name and access their role information, under Load user groups.

- Activate the certification_body checkbox.

- Save the changes in Save user groups.

- The Coordinator must contact each member of the CAB-team, to notify them about their responsibilities as Assessor and thus give continuity to the certification.

Designation of Reviewers

- If the Reviewers|Reviewer user does not have the required role:

- Login to the special page User Rights]

- Enter the user's name and access their role information, under Load user groups.

Activate the checkbox certification_reviewer ** Save the changes in Save user groups. Save the changes in Save user groups ** Save the changes in Save user groups.

- Go to the Project page, action Edit, tab Certification Manager.

- In the Reviewer 1 to 3 fields, select the user that will be Reviewer.

- Save the changes in Save page.

Approval of the Certification Document

After the CAB-team, has issued the Certification Document, the Coordinator must carry out the respective steps for the approval of this document, which includes:

- Approval and signature of Authorities by OHO.

- Approval and signature of Authorities by the external certification body for validation according to DIN Spec 3105.

Reviewers

The Reviewers have the task to technically analyse all the Project documentation, for which, they must have gone through the registration process in the same way as for the Applicant. It must also have the role of certificarion_reviewer, as indicated in Reviewer designation.

Each Reviewer must comply with the aspects mentioned below:

Analysis of Technical Documentation

- Enter the project page.

- Analyse all available information, especially the assembly instructions, which includes:

- Correct references between parts in the Technical drawings and the Parts list .

- Well explained manufacturing processes for special parts or joining means.

- Consistency in the information shown, it must make sense in technical and [Open Hardware] terms.

Release of non-conformities

On the project page, comments on technical aspects can be made, these comments are the channel in which non-conformities are issued.

A comment or non-conformity must be issued in the following cases:

- Information is missing in order to be able to classify or recognise a part or assembly.

- Information about a supplier is missing (links to websites tend to be modified).

- Missing information on a purchased part, in order to be able to locate it in current markets.

- Missing measurements or other specifications in the Technical drawings.

- Lack of coherence in the specifications, with respect to the assembly of the parts.

- Missing fields in the Parts list.

- Depending on the type of assembly:

- There must exist for each part, a plan in PDF and its respective CAD file (the latter, with the purpose of being able to review the 3D information in other CAD systems different from the one that has generated the parts).

- The 3D printing parts must be accompanied by their STL file, in addition to their PDF drawing and their CAD file.

- For printed circuit boards (PCB), the addresses of their components must be included.

- In case of confusing information or obvious mistakes, a friendly comment should be left, pointing out the mistake in the corresponding item.

- In case of problems regarding the Project in general, there is an extra field in the Parts list, where comments can be added

- Those items that require some correction by the Applicant, must be marked as Action required, in the Project page, action Edit, tab Part list.

- This process can be repeated as long as there are comments or non-conformities with corrections to be made and not all the items of the Part list are approved, through which, communication with the Applicant must always be maintained.

Project Approval

After all non-conformities have been resolved, you should:

- Mark each item in the Part list as Approved, on the Project page, action Edit, tab Part list.

- Add a final comment including OK, FINISHED.

- Notify the Coordinator|Coordinator, about the Project Approval.

Equipo de evaluación de conformidad (CAB)

El Equipo CAB tiene acceso los datos de contacto de los Revisores y del Aplicante, pudiendo siempre intervenir en la resolución de no coformidades y obteniendo información directa para la emisión del Documento de Certificación.

Validación de información del Aplicante y los Revisores

Entre algunas de las actividades del Equipo CAB, se tiene:

- Verifica algunas formalidades del Proyecto.

- En conjunto con el Coordinador Apertura el Certification processes ya que participa en la Designación de Revisores.

Emisión del Documento de Certificación

Una vez que el Aplicante haya ingresado toda la Documentación técnica, al menos dos veces, el Equipo CAB puede emitir una certificación donde se valide el cumplimiento de la DIN Spec 3105. Esto culmina el proceso de revisión, el cual pudiera ser abierto si:

- Alguna persona presenta quejas ante el Equipo CAB por:

- La publicación de la documentación ya no es accesible total o parcialmente.

- Los términos de la licencia se han modificado y ya no cumplen con los requisitos de la norma DIN Spec 3105.

- Cualquier información relevante ha sido alterada o eliminada de la Certifcation platform.

- Teniendo en cuenta la importancia de las quejas presentadas, el Equipo CAB puede anular la certificación en curso y volver a abrir el Certification processes una nueva revisión de la Technical documentation.

- El Aplicante puede subir nuevamente documentación que ya ha sido certificada y aprobada, en este caso, la misma no requiere ser revisada otra vez.